Wire harness stripping device in low-voltage box

A wire harness and low-voltage technology, which is applied in the field of wire harness stripping devices in low-voltage boxes, can solve problems such as unsustainable operations, increase labor costs, and prolong the production cycle of wire harnesses, so as to achieve the effects of improving efficiency, shortening production cycle, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

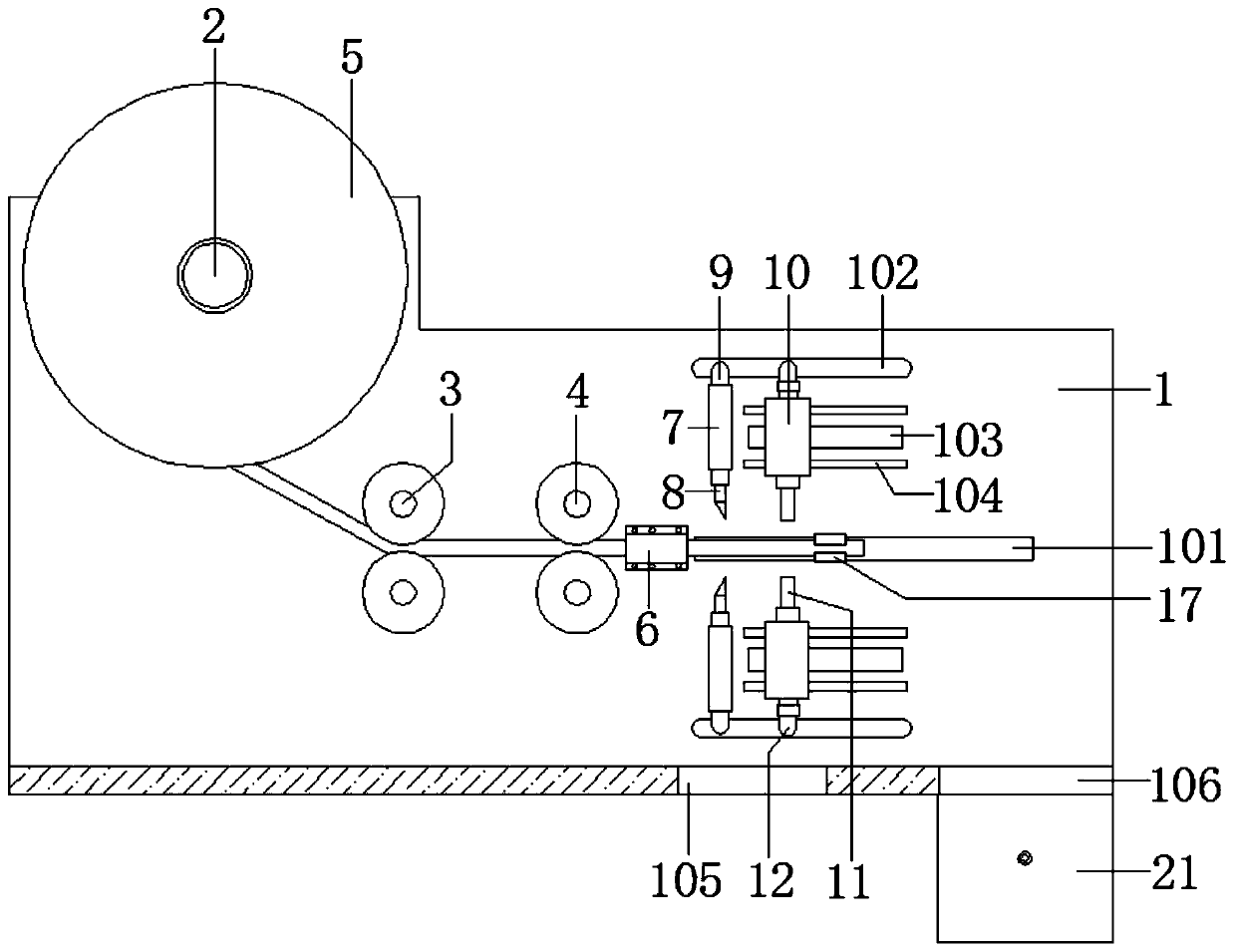

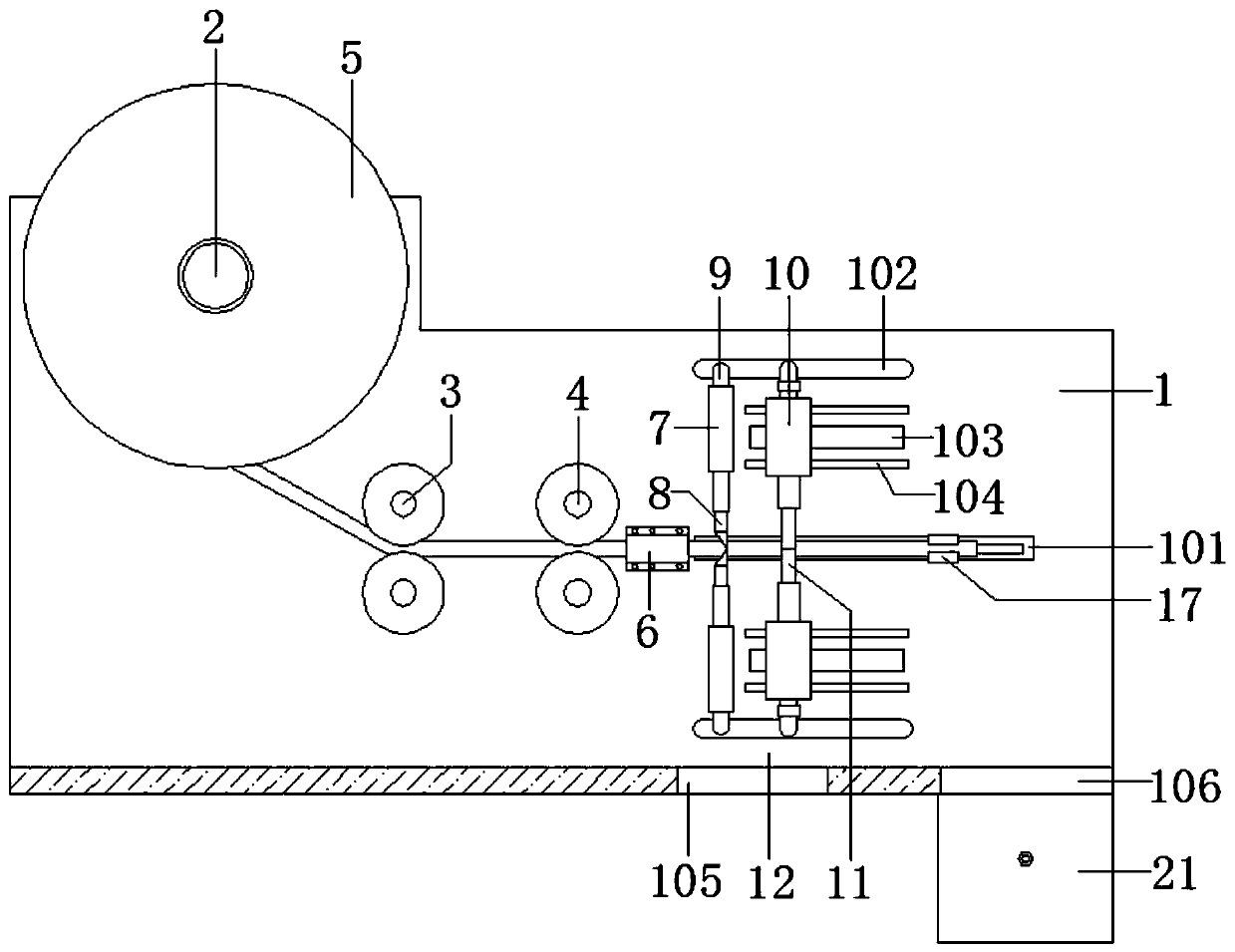

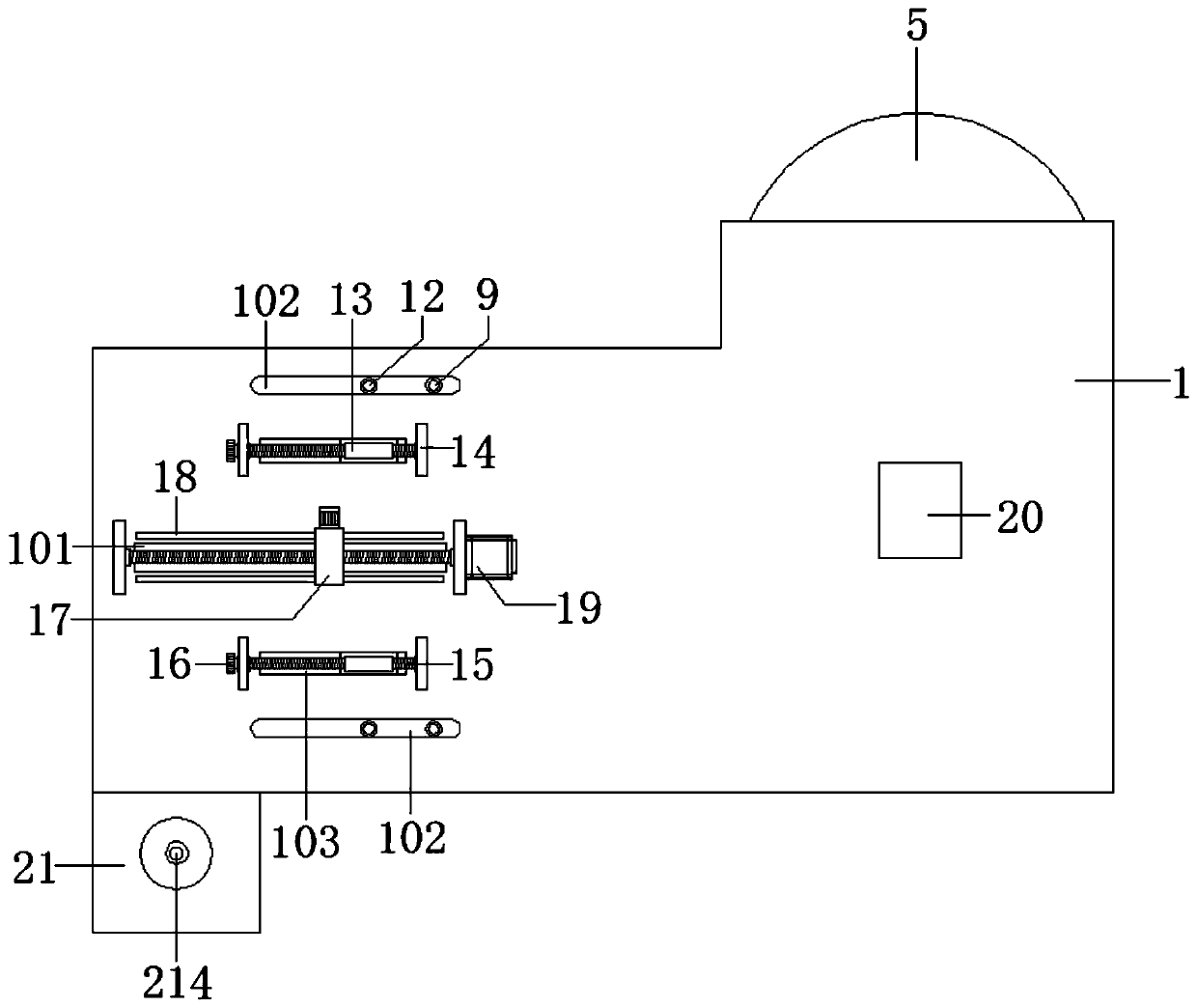

[0030] A wire harness stripping device in the low-voltage box of this embodiment, combined with the attached Figure 2-9 See attached figure 1 : A wire harness peeling device in a low-voltage box, including an L-shaped base plate 1, an installation shaft 2 is rotated on the left side of the L-shaped base plate 1, and a guide roller group 3 and a conveying roller group 4 are respectively arranged on the lower right side of the installation shaft 2, The guide roller set 3 and the conveying roller set 4 are arranged horizontally and are both rotatably connected to the side wall of the L-shaped base plate 1, and the rear side wall of the L-shaped base plate 1 is installed to drive one of the rollers in the conveying roller set 4 to rotate. The right side of the conveying roller set 4 is provided with a positioning block 6, and the side wall of the L-shaped base plate 1 is provided with an opening 101, the opening 101, the positioning block 6 are aligned with the horizontal positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com