Data line stripping device based on current heating principle

A data cable and principle technology, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of easy loosening of nylon data cable cuts and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

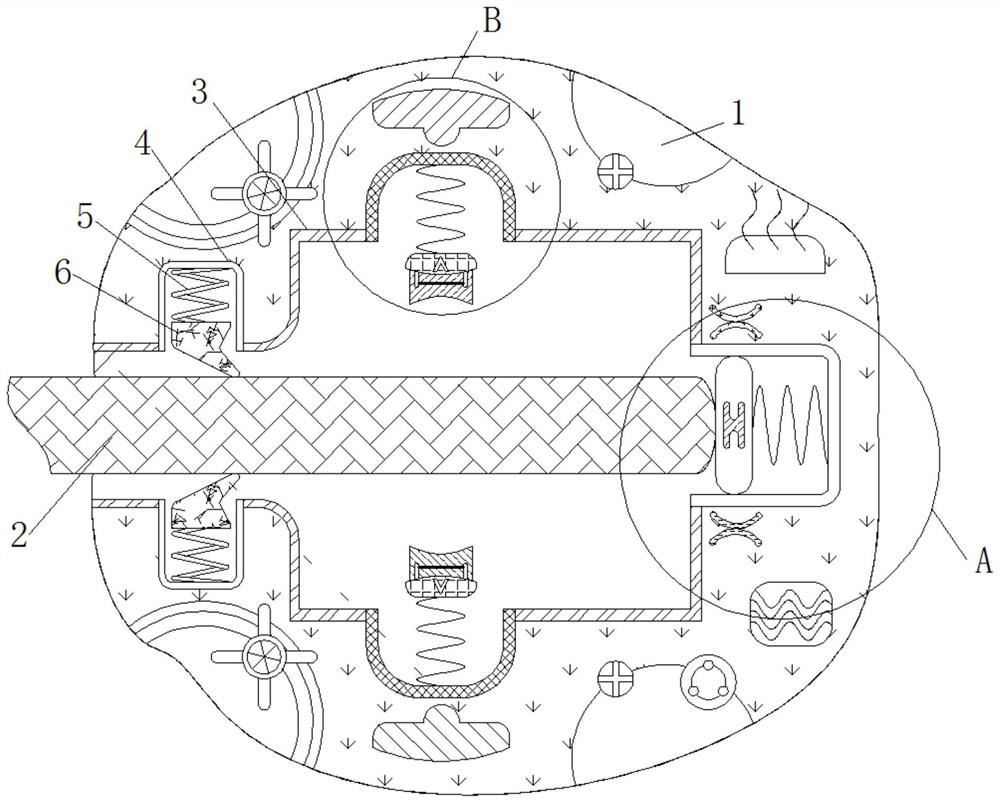

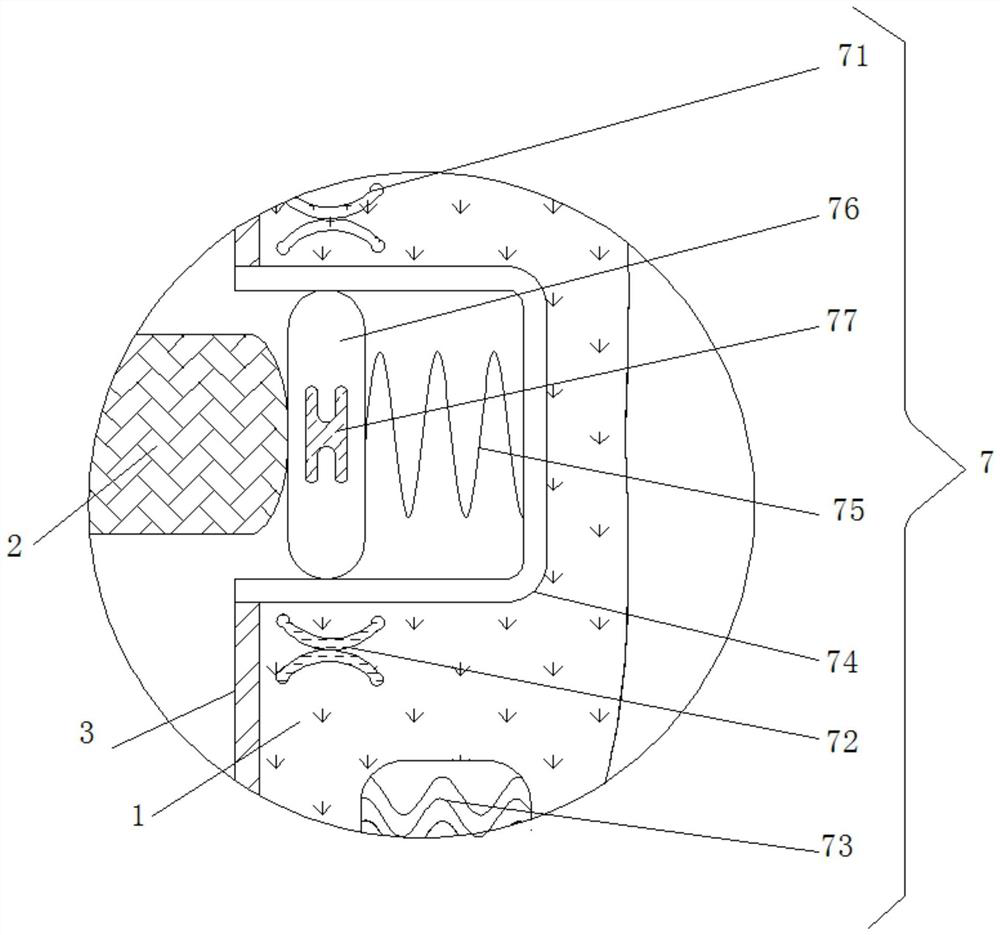

[0026] see figure 1 and figure 2 , a data line stripping device based on the principle of current heating, comprising a housing 1 and a nylon cable 2, the inner wall of the housing 1 is fixedly connected with a cutting chamber 3, the inner wall of the housing 1 and the outer side near the cutting chamber 3 is fixedly connected with The fixed groove 4, the outside of the fixed groove 4 inner wall is fixedly connected with a spring one 5, the inner side of the spring one 5 is fixedly connected with a pressing block 6, the cross section of the bottom of the pressing block 6 is triangular, and the pressing block 6 is a hard high-strength material, The triangular design of the pressing block 6 can make the cut skin of the nylon cable 2 can be easily pressed and peeled off when the nylon cable 2 is pulled out. The inner wall of the housing 1 and the right side close to the cutting cavity 3 are fixedly connected with the extrusion assembly 7. The housing The inner wall of 1 and the...

Embodiment 2

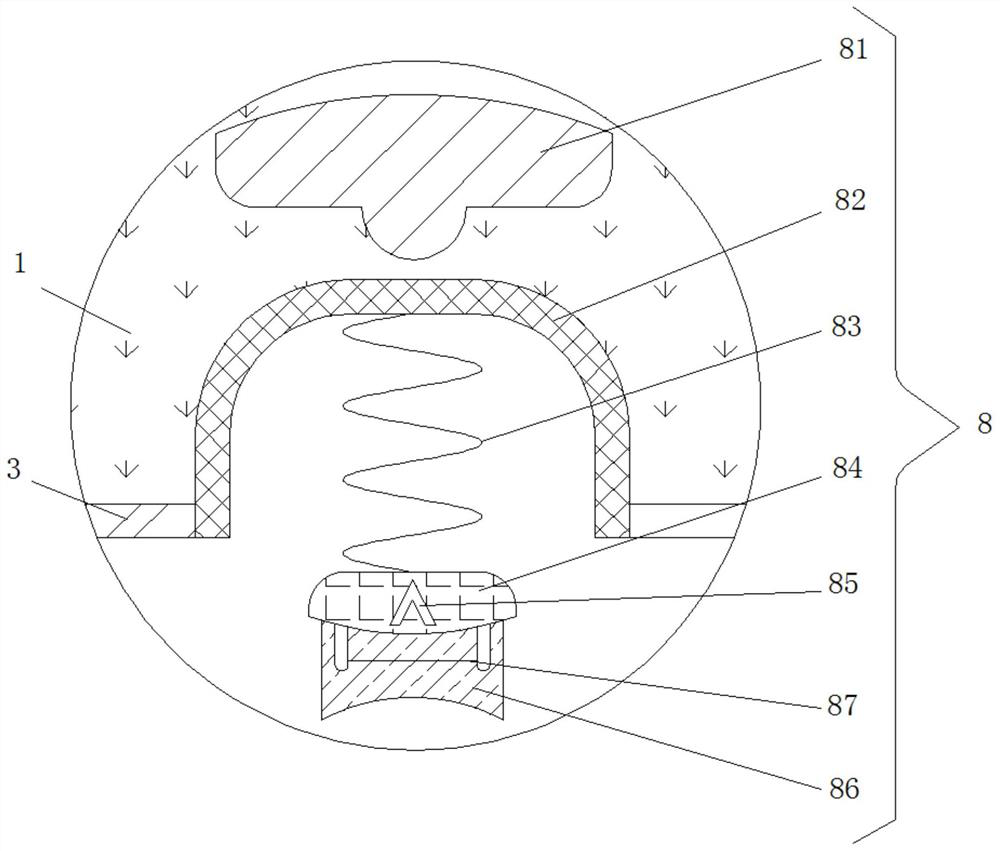

[0029] see figure 1 and image 3 , a data line stripping device based on the principle of current heating, comprising a housing 1 and a nylon cable 2, the inner wall of the housing 1 is fixedly connected with a cutting chamber 3, the inner wall of the housing 1 and the outer side near the cutting chamber 3 is fixedly connected with The fixed groove 4, the outside of the fixed groove 4 inner wall is fixedly connected with a spring one 5, the inner side of the spring one 5 is fixedly connected with a pressing block 6, the cross section of the bottom of the pressing block 6 is triangular, and the pressing block 6 is a hard high-strength material, The triangular design of the pressing block 6 can make the cut skin of the nylon cable 2 can be easily pressed and peeled off when the nylon cable 2 is pulled out. The inner wall of the housing 1 and the right side close to the cutting cavity 3 are fixedly connected with the extrusion assembly 7. The housing The inner wall of 1 and the ...

Embodiment 3

[0033] see Figure 1-4 , a data line stripping device based on the principle of current heating, comprising a housing 1 and a nylon cable 2, the inner wall of the housing 1 is fixedly connected with a cutting chamber 3, the inner wall of the housing 1 and the outer side near the cutting chamber 3 is fixedly connected with The fixed groove 4, the outside of the fixed groove 4 inner wall is fixedly connected with a spring one 5, the inner side of the spring one 5 is fixedly connected with a pressing block 6, the cross section of the bottom of the pressing block 6 is triangular, and the pressing block 6 is a hard high-strength material, The triangular design of the pressing block 6 allows the cut skin to be easily pressed and peeled off when the nylon cable 2 is pulled out;

[0034] The inner wall of the housing 1 and the right side close to the cutting chamber 3 are fixedly connected with an extruding assembly 7, and the inner wall of the housing 1 and near the top and bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com