High-speed machining and automatic measuring integrated equipment

An automatic measurement and high-speed technology, applied in metal processing equipment, working carrier, grinding/polishing equipment, etc., can solve the problems of low production efficiency and low removal efficiency of hard and brittle materials, and achieve high processing efficiency and good chip removal effect , the effect of not easy to scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

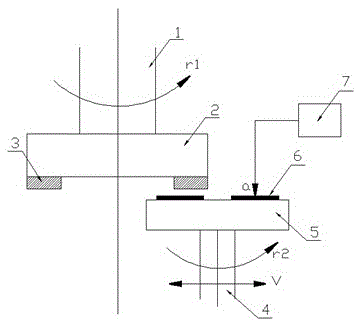

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. combine figure 1 , the positions marked in the figure are spindle 1, grinding wheel 2, diamond layer 3 on the surface of the grinding wheel, workpiece shaft 4, porous ceramic disc 5, workpiece 6, and online thickness measuring instrument 7. The most obvious difference between the structure of this equipment and the traditional grinding and polishing equipment is that the upper and lower discs are not on the same axis. The main structure includes: main shaft 1, diamond grinding wheel 2, workpiece shaft 4 and porous ceramic disc 5. An ultrasonic vibration device is connected to the workpiece shaft 1, which can perform ultrasonic vibration along the axial direction, and the vibration is transmitted to the grinding wheel 2, which can speed up the removal rate of the material 6. The diamond layer 3 on the surface of the grinding wheel is an agglomerated structure, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com