Clean glass column circular head grinding device

A grinding device and glass column technology, applied in grinding devices, grinding/polishing safety devices, grinding machine tools, etc., can solve the problems of not meeting the needs of processing, being too rough, and expensive, achieving low cost, maintaining The effect of cleaning and preventing the spread of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be further described in detail below.

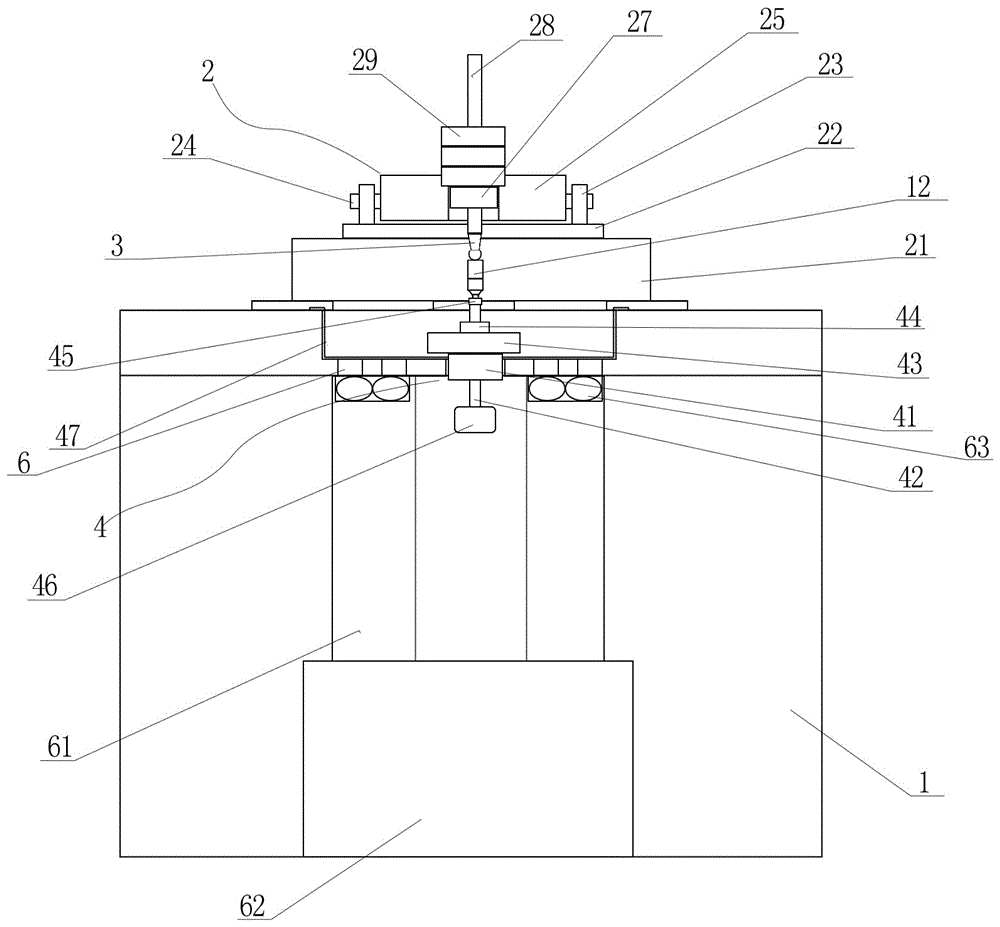

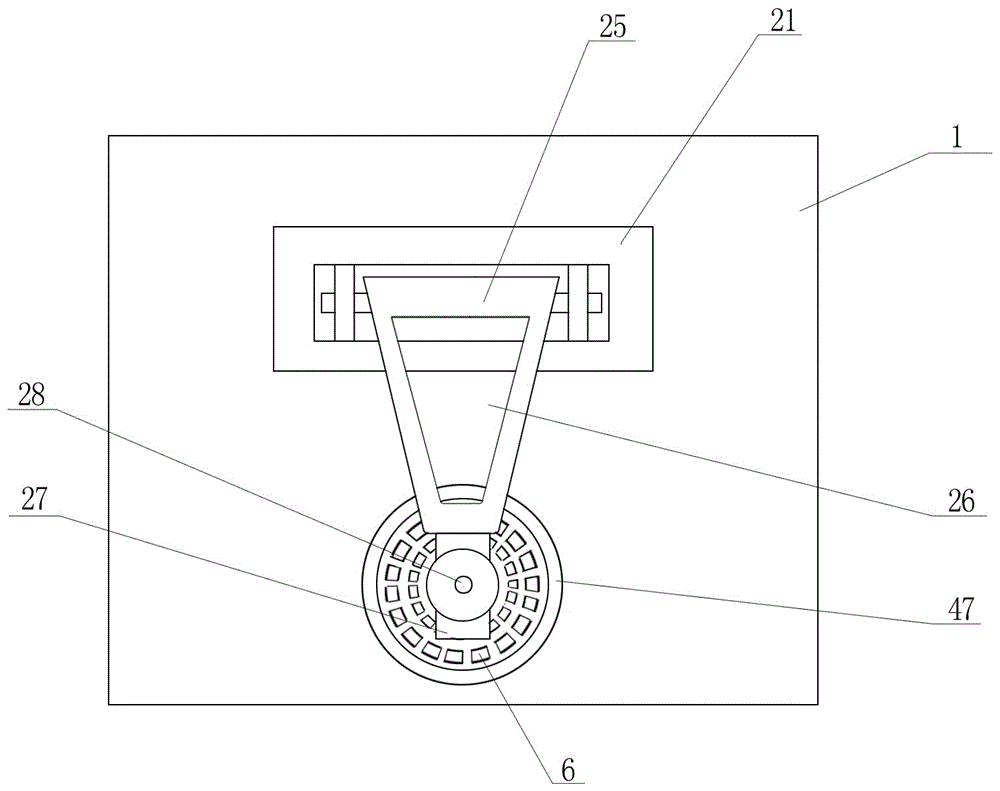

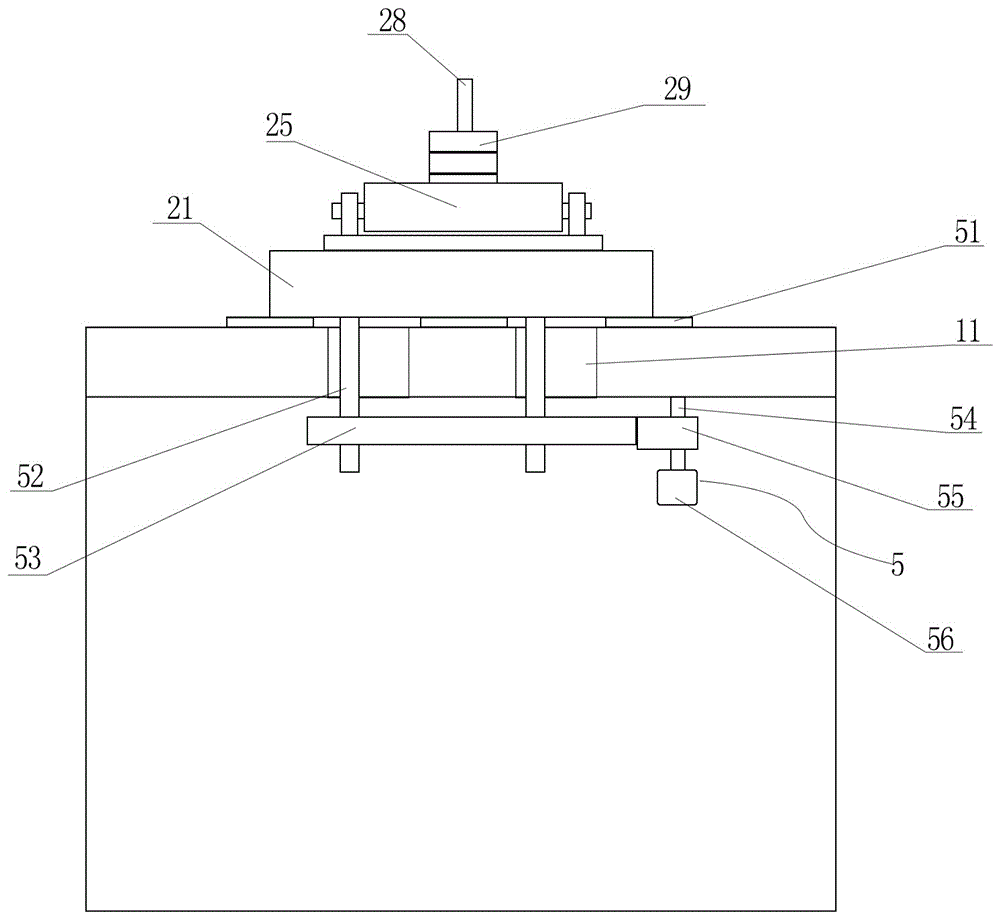

[0015] Such as Figure 1 to Figure 3 As shown, a clean type glass column round head grinding device of the present invention includes a frame 1, which is characterized in that: a fixed assembly 2 and a grinding assembly 4 are correspondingly arranged on the frame 1, and a driving and fixing assembly is arranged in the frame 1. Component 2 drives component 5 for reciprocating movement.

[0016] The fixing assembly 2 includes a support 21, and a fixing plate 22 is arranged on the support 21. A vertical plate 23 is arranged vertically at both ends of the fixing plate 22, and a through hole is correspondingly arranged on the vertical plate 23, and a roller is connected between the two through holes. Axle 24, a tripod 25 that can rotate with the roller shaft 24 is socketed on the roller shaft 24, and the front end of the tripod 25 is connected with a fixed block 27, and a vertical bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com