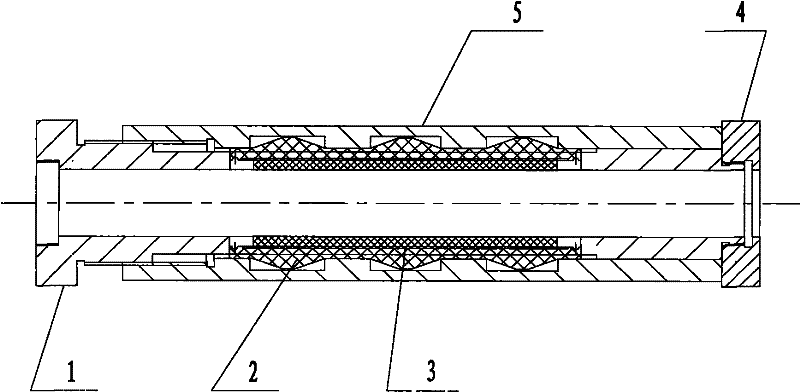

Cylindrical grinding device

A technology of cylindrical grinding and outer casing, which is applied in the direction of grinding/polishing equipment, grinding machines, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problems of low production efficiency, length constraints of workpieces, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

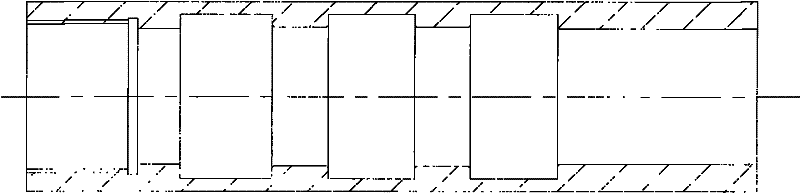

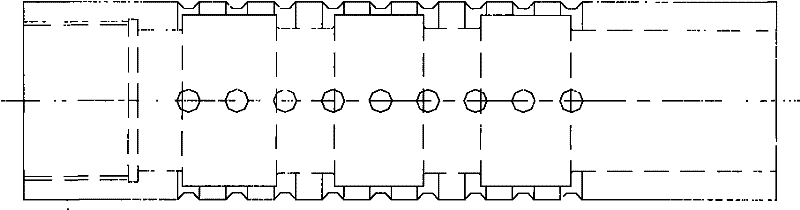

[0019] In the cylindrical grinding device, the inner casing is sleeved in the outer casing and one end of the inner casing and the outer casing are connected by threads, the other end of the inner casing is connected with a retaining ring, and the retaining ring presses the outer casing. Four rows of circular through holes are evenly distributed on the outer surface of the outer casing, and four stepped through grooves are evenly distributed in the circumferential direction on the side wall of the inner casing. The circular through holes and the stepped through grooves are arranged in a staggered arrangement. The circular through holes are used to remove grinding waste during processing, and the four rows of circular through holes should be staggered with the four through grooves of the inner casing when the device is installed. The sand bar is fixed on the sand bar frame, and the sand bar frame is fixed in the stepped channel on the inner casing. Grooves are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com