Wafer grinding head and wafer adsorption method

A grinding head and wafer technology, which is applied in the directions of grinding machine tools, grinding tools, grinding devices, etc., can solve the problems of further improving the grinding quality of wafers and increasing the manufacturing cost of grinding heads without explanation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

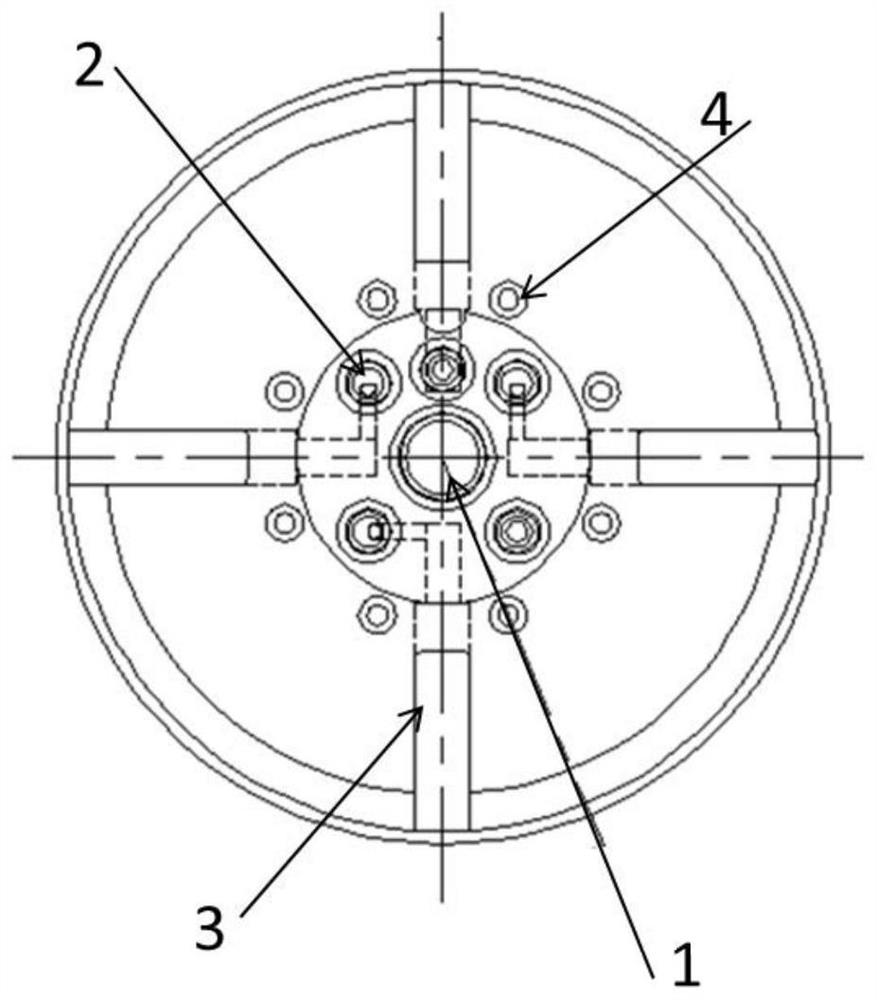

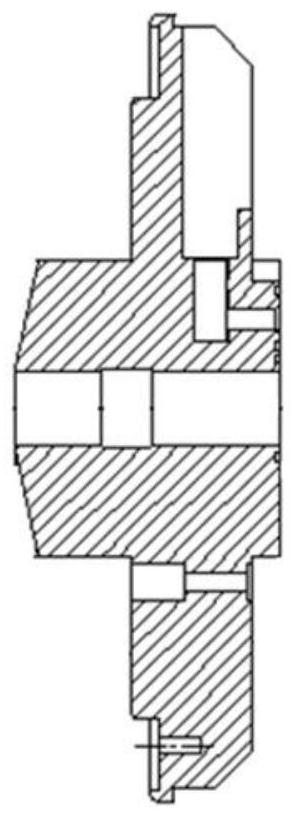

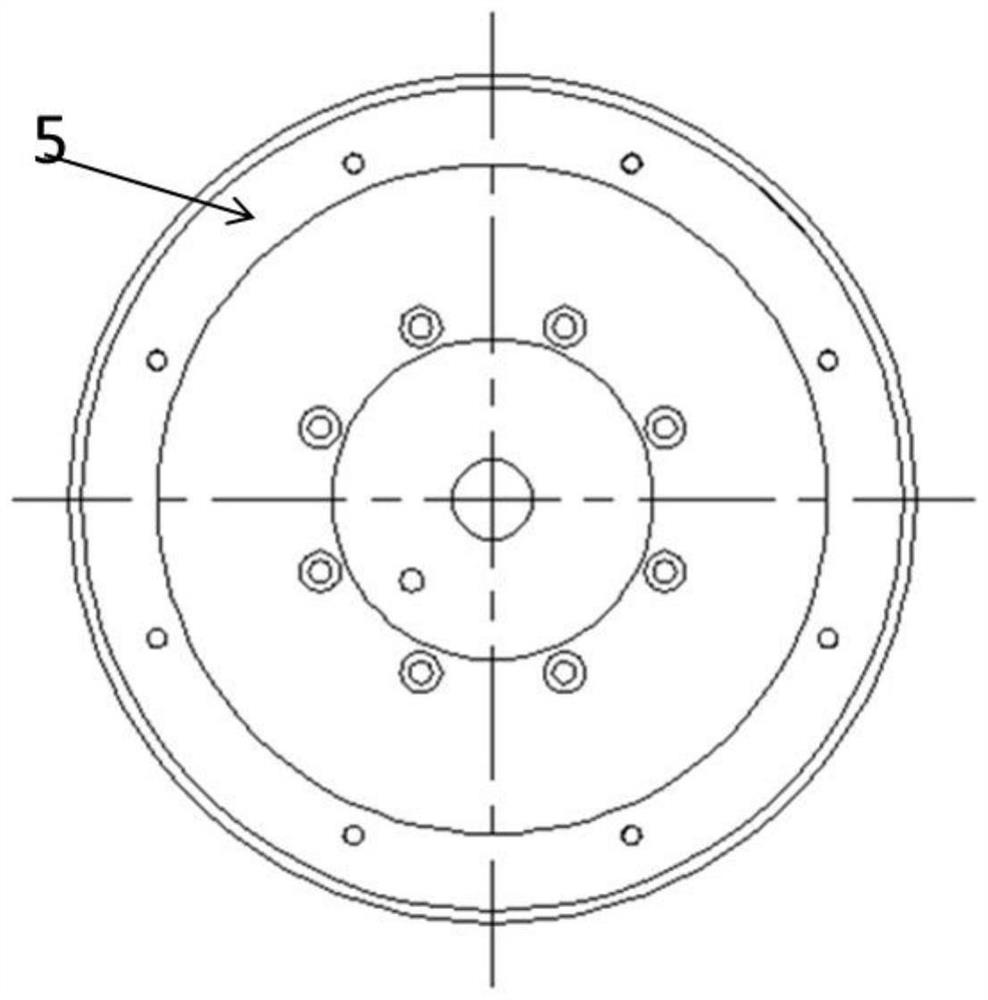

[0064] This embodiment provides a wafer grinding head, the front top view of the wafer grinding head is as follows figure 1 As shown, the top view of the bottom surface is shown as image 3 As shown, the side sectional view is shown as figure 2 shown.

[0065] The wafer grinding head provided by this embodiment includes a grinding head body and a fixing device surrounding the periphery of the grinding head body; the fixing device includes a closely arranged first ring and a second ring; the grinding head body, the first The ring remains concentric with the second ring; the grinding head body is provided with a first air path 1 and a second air path 2; the first ring is evenly provided with a ventilation groove 3; the ventilation groove 3 communicates with the second gas path 2.

[0066] The shape of the grinding head body includes a cylinder; the diameter of the grinding head body is 76.2 mm; the height of the grinding head body is 67.85 mm.

[0067] The first gas path 1 ...

Embodiment 2

[0073] This embodiment provides a wafer grinding head, the difference between the wafer grinding head and Embodiment 1 is that the ring groove is omitted in this embodiment.

Embodiment 3

[0075] This embodiment provides a wafer grinding head, the difference between the wafer grinding head and Embodiment 1 is that this embodiment is provided with three ventilation grooves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com