Machine tool for grinding glass drill

A glass and machine tool technology, applied in the field of glass drilling and grinding machine tools, can solve the problems of low efficiency of manual screening, unpleasant smell, pollution, etc., and achieve the effects of high production efficiency, low labor cost, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

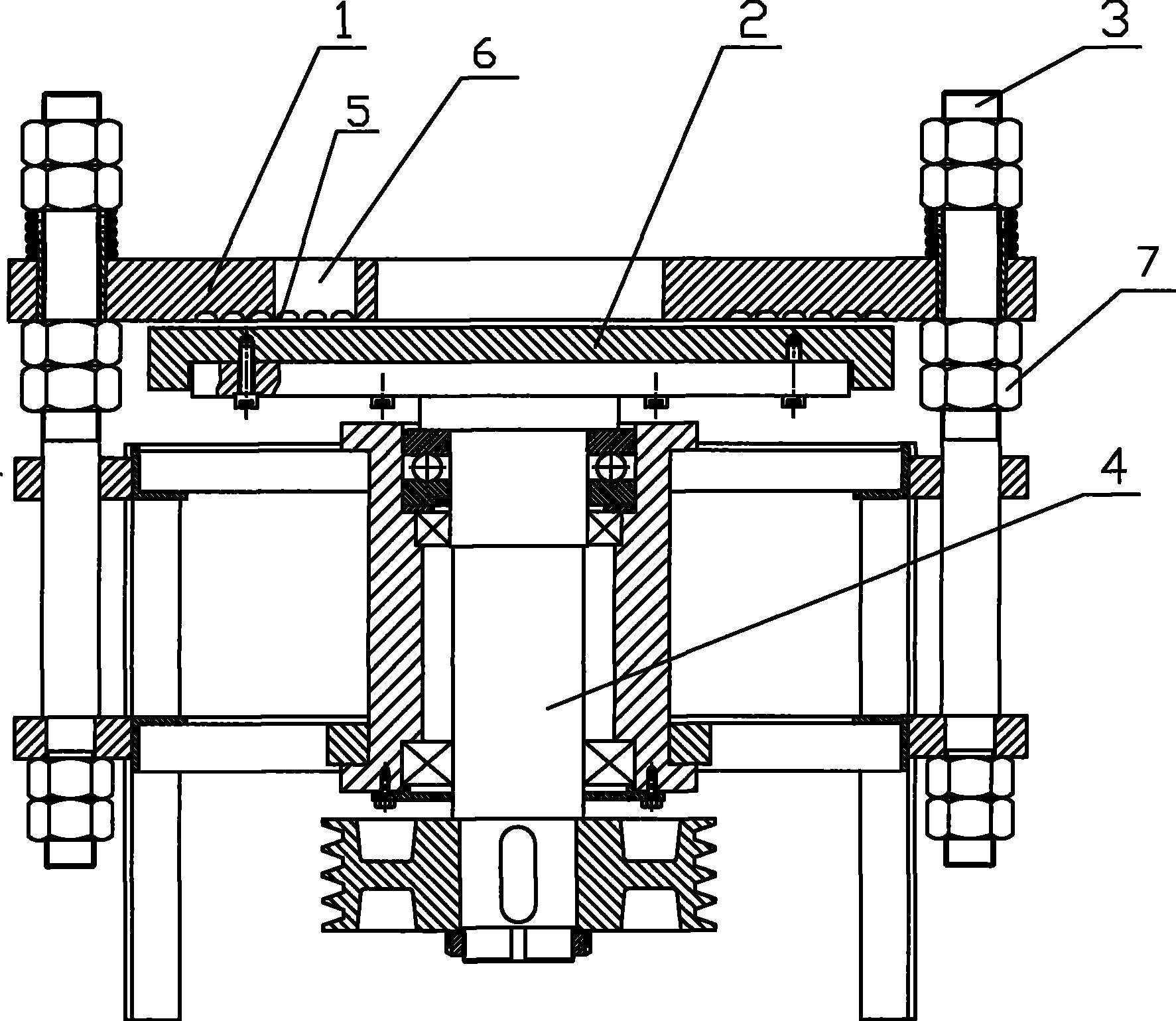

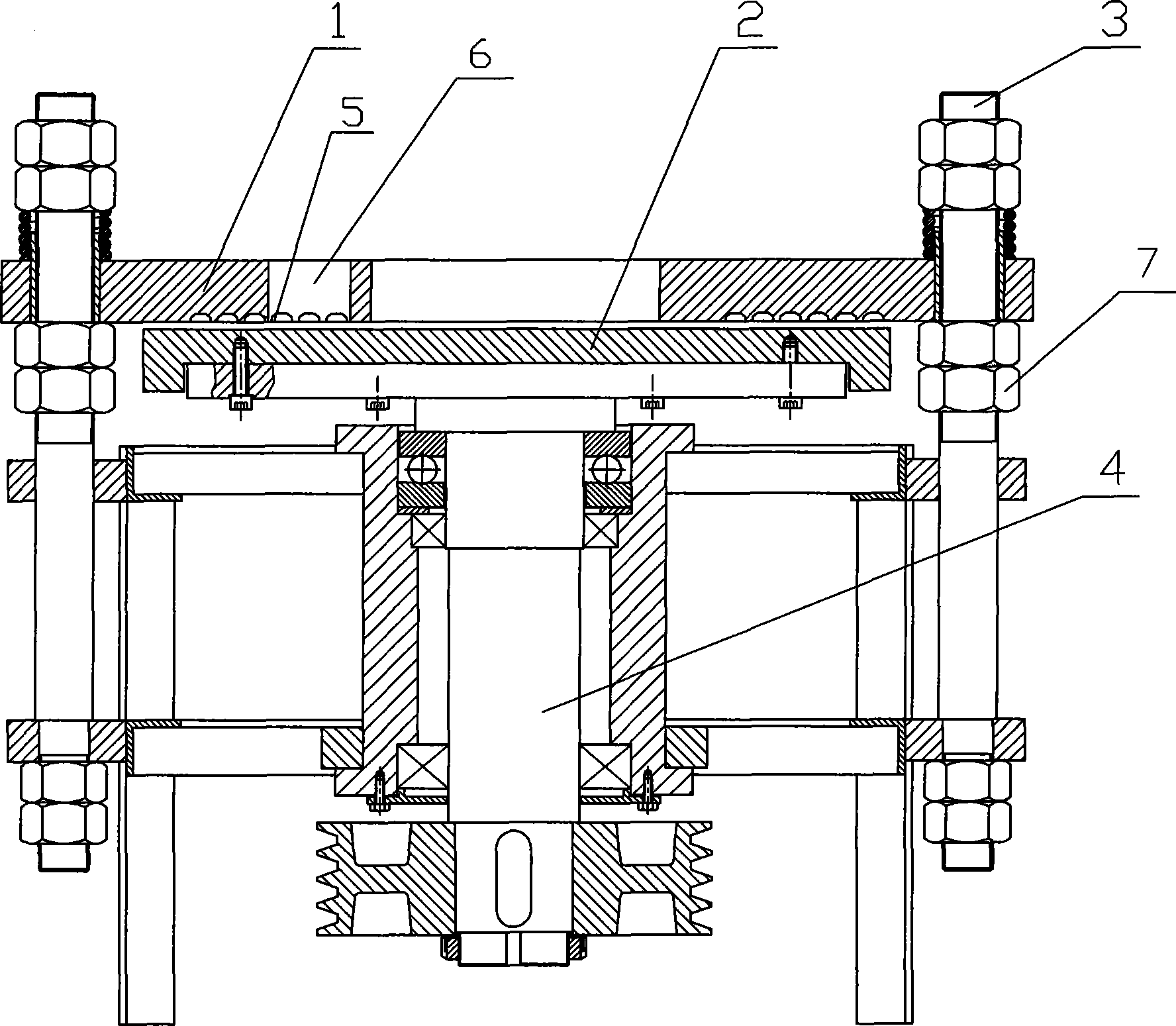

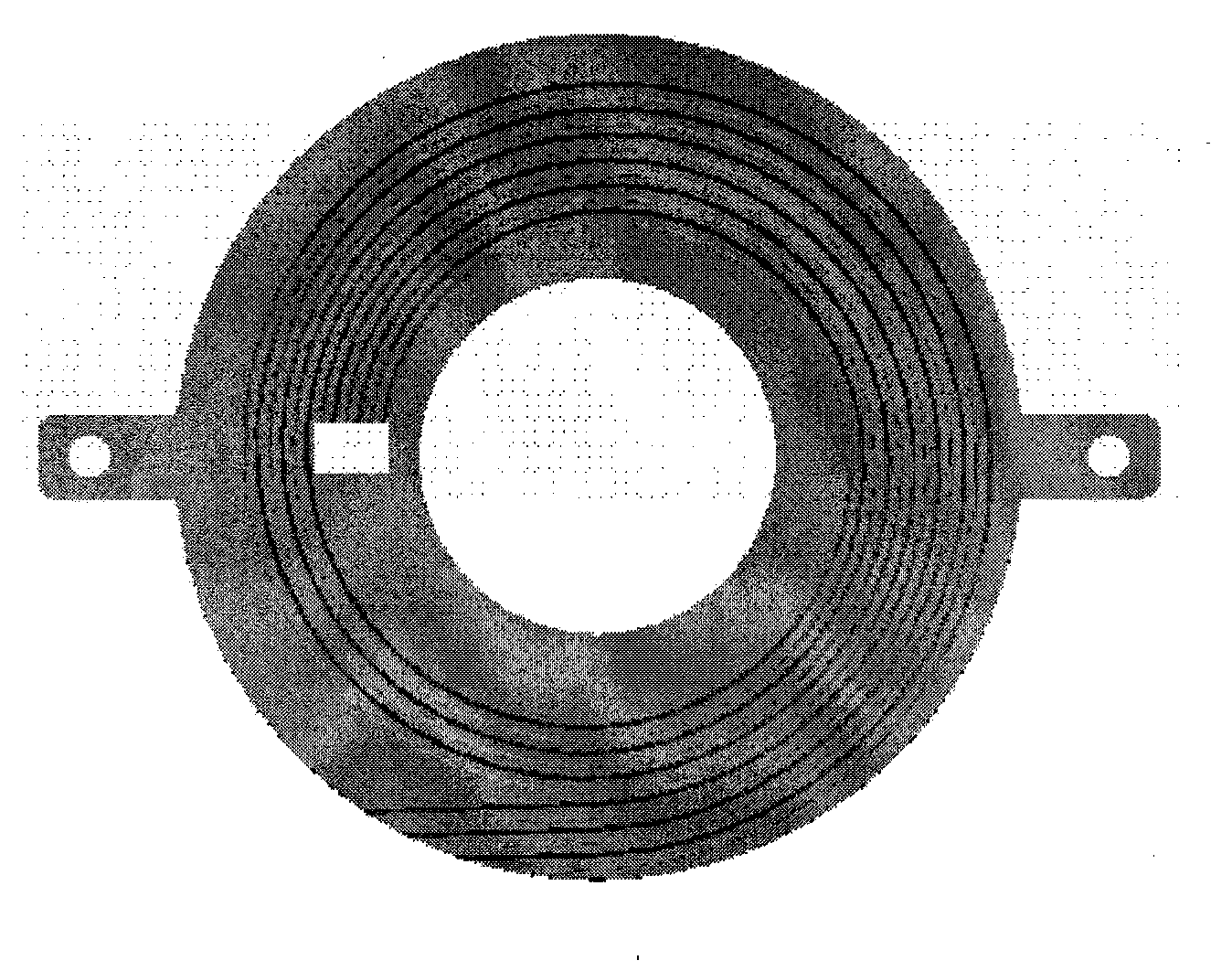

[0014] Referring to Figure 1-2: a glass drilling and grinding machine tool, including a frame, and a main shaft 4 rotatably arranged in the frame. The material guide plate 1 of the material opening 6, the height of the material guide plate 1 is adjustable on the frame, the gap between the material guide plate 1 and the grinding disc 2 constitutes the grinding work area, and the material guide plate 1 faces the grinding disc 2 One side is provided with a helical track 5 whose section is suitable for the glass drill, the inlet of the helical track 5 communicates with the feed port 6 , and the outlet of the helical track 5 extends to the outer edge of the material guide plate 1 . The spiral track 5 is an equidistant spiral line.

[0015] Both sides of the frame are separately provided with columns 3, and the material guide plate 1 is sleeved on the column 3, and height a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com