Special grinding aid for calcium carbonate powder and use method of special grinding aid

A technology of calcium carbonate powder and grinding aid, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of single performance, poor adaptability, easy desorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

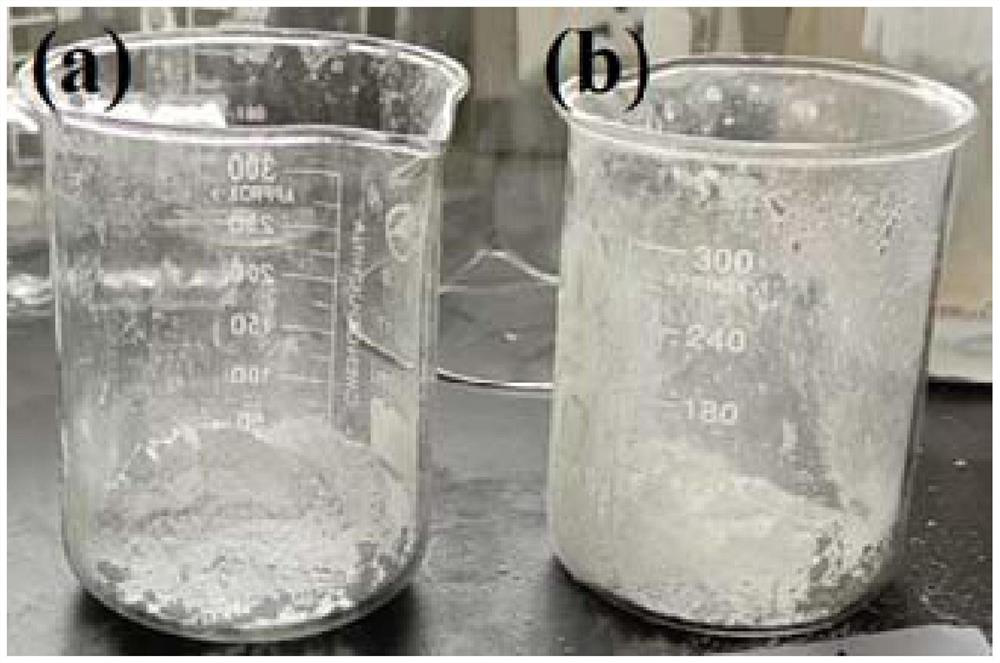

Image

Examples

Embodiment 1

[0024] First mix sodium dodecylbenzenesulfonate and monoethanolamine evenly, then add water, the mass ratio of sodium dodecylbenzenesulfonate, monoethanolamine and water is 1:0.5:1, stir evenly, and stand still until there is no Foam is prepared to obtain component A; then cryogenic crushing process is used to crush triglycerides, and after crushing, the powder is collected through a 150-mesh vibrating sieve, and then γ-aminopropyltriethoxysilane with a mass of 0.1% of the powder is added, and stirred Evenly prepared component B.

[0025] Before using the grinding aid prepared by the present invention, add a certain proportion of component A and component B into water and stir, wherein the mass of water is 20 times the sum of the mass of component A and component B, and spray it on the calcite ore after stirring Surface (addition is 0.1% of ore quality), adopt vertical mill to pulverize and prepare 2200 order calcium carbonate powder, the calcium carbonate powder parameter tha...

Embodiment 2

[0041]First, mix sodium benzenesulfonate and diethanolamine evenly, then add water, the mass ratio of sodium benzenesulfonate, diethanolamine and water is 1:10:100, stir evenly, and wait until there is no foam on the surface to prepare component A; then Stearic acid was pulverized by cryogenic pulverization, and the powder was collected through a 150-mesh vibrating sieve, then 0.5% of the powder mass was added to the stearic acid, and the component B was prepared by stirring evenly.

[0042] Before using the grinding aid prepared by the present invention, add a certain proportion of component A and component B into water and stir, wherein the mass of water is 100 times the sum of the mass of component A and component B, and spray it on the calcite after stirring The surface of the ore (the addition amount is 0.2% of the mass of the ore) was pulverized by a jet mill to prepare 3000 mesh calcium carbonate powder.

[0043] Adding the grinding aid increases the output by about 11%...

Embodiment 3

[0048] First, mix sodium lignosulfonate and diglycolamine evenly, then add water, the mass ratio of sodium lignosulfonate, diglycolamine and water is 1:2:8, stir evenly, and let it stand until there is no foam on the surface. Prepare component A; then crush glyceryl monostearate by cryogenic crushing process, collect the powder through a 150-mesh vibrating sieve after crushing, then add γ-aminopropyltriethoxysilane with a mass of 0.2% of the powder, and stir Evenly prepare component B.

[0049] Before using the grinding aid prepared by the present invention, add a certain proportion of component A and component B into water and stir, wherein the mass of water is 50 times the sum of the mass of component A and component B, and spray it on the calcite after stirring The surface of the ore (the addition amount is 0.15% of the mass of the ore) was pulverized by a vertical mill to prepare 2800 mesh calcium carbonate powder.

[0050] Adding the grinding aid increases the output by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com