Cement grinding aid and preparation method thereof

A cement grinding aid and solution technology, which is applied in the field of cement additives, can solve the problem that the grinding effect of grinding materials cannot be maximized, and achieve the effect of improving the adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

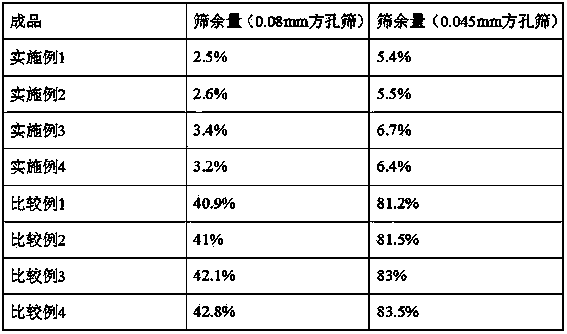

Examples

Embodiment 1

[0016] Embodiment 1 - the preparation method of cement grinding aid

[0017] It uses the following raw materials:

[0018] 20kg of triethanolamine, 12kg of calcium formate solution, 5kg of supersaturated urea solution, 4kg of polyethylene glycol, 1kg of sodium citrate, 2kg of molasses, and 20kg of water;

[0019] Its preparation method is as follows: first stir and mix triethanolamine, calcium formate solution, sodium citrate, molasses and water, then heat to 105°C, and stir at constant temperature for 60 minutes; then, cool down to 40°C, add supersaturated urea solution and polyethylene glycol Diol, and continue stirring at constant temperature for 30min.

Embodiment 2

[0024] Embodiment 2——the preparation method of cement grinding aid

[0025] It uses the following raw materials:

[0026] 22kg of triethanolamine, 11kg of calcium formate solution, 2kg of supersaturated urea solution, 1kg of polyethylene glycol, 3kg of sodium citrate, 3kg of molasses, and 22kg of water;

[0027] Its preparation method is as follows: first stir and mix triethanolamine, calcium formate solution, sodium citrate, molasses and water, then heat to 110°C, and stir at constant temperature for 50 minutes; then, cool down to 45°C, add supersaturated urea solution and polyethylene glycol Diol, and continue stirring at constant temperature for 20min.

Embodiment 3

[0032] Embodiment 3——the preparation method of cement grinding aid

[0033] It uses the following raw materials:

[0034] Triethanolamine 25kg, calcium formate solution 10kg, supersaturated urea solution 4kg, polyethylene glycol 2kg, sodium citrate 2kg, molasses 2.5kg, water 28kg;

[0035] Its preparation method is as follows: first stir and mix triethanolamine, calcium formate solution, sodium citrate, molasses and water, then heat to 120°C, and stir at constant temperature for 40 minutes; then, cool down to 48°C, add supersaturated urea solution and polyethylene glycol Diol, and continue stirring at constant temperature for 25min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com