Welding fixture for electronics manufacturing and operating method thereof

A welding tooling and electronic technology, applied in manufacturing tools, separation methods, welding equipment, etc., can solve the problems of dry smoke inhaling the human body, not having a dry smoke absorption device, harming the human body, etc., to reduce the use of wires, convenient storage and placement, convenient The effect of powered lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

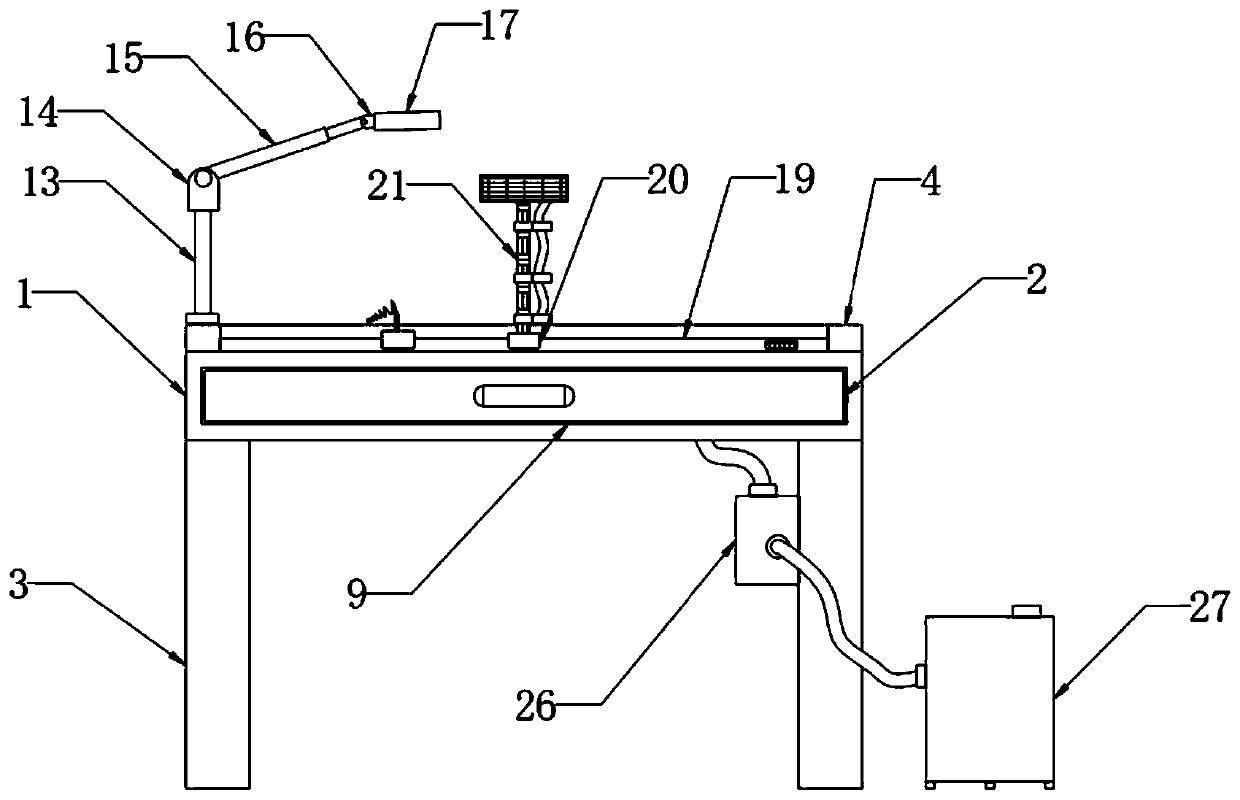

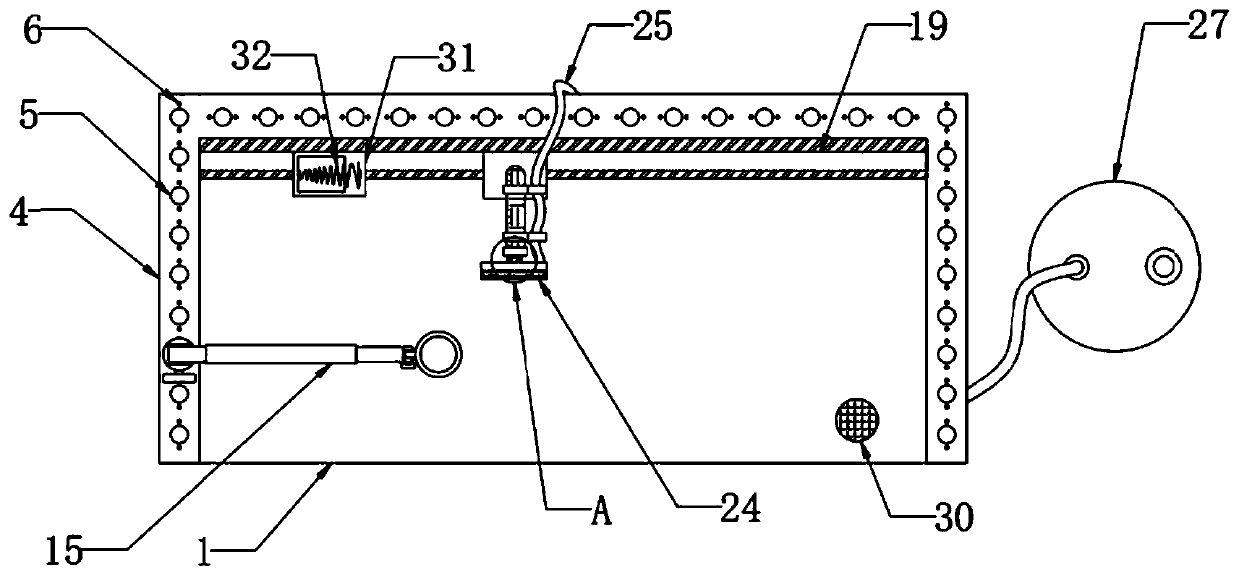

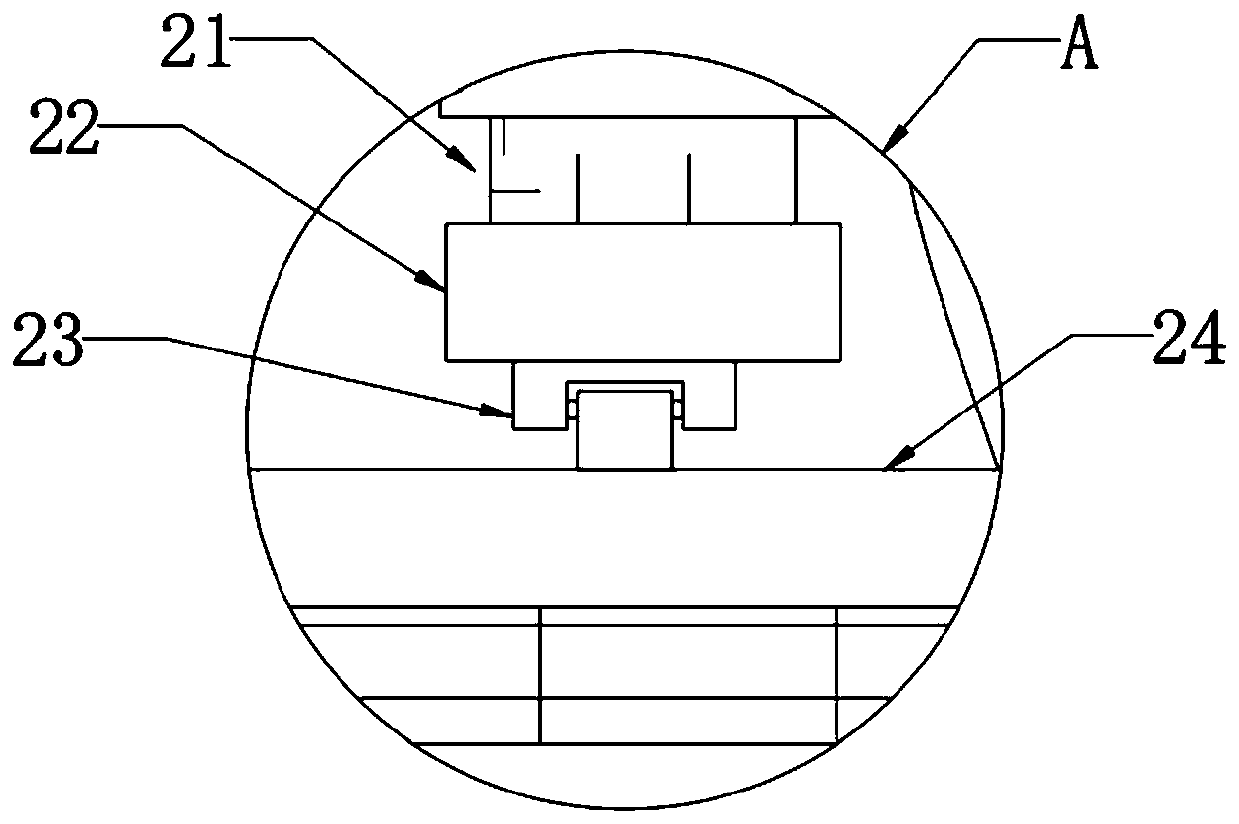

[0042] Embodiment 1: When using this device to solder electronic products, first slide the first sliding seat 20 and move the gooseneck 21 to move the smoking box 24 to the position where dry smoke needs to be absorbed, and then adjust the smoking box 24 up and down, left and right , so as to more accurately and adjust the suction position and angle of the smoking box 24, and then turn the control knob 30 to turn on the air pump 26, so that the dry smoke is first absorbed into the smoke guide pipe 25 through the smoking box 24, and then the dry smoke passes through the air pump 26, guides The smoke pipe 25 is finally discharged into the alum water inside the filter box 27 through the smoke exhaust box 28, and then the toxic gas in the dry tobacco is filtered and dissolved through the alum water, and the filtered gas leaves the alum water and finally is discharged through the gas outlet 29 Filter the inside of the box 27, and adjust the control knob 30 by turning it, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com