Manufacturing method of electronic product case

A manufacturing method and technology of electronic products, which are applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of inability to effectively guarantee the electroplating process, difficult laser activation process, time-consuming and labor-intensive grooves, etc. The effect of enhancing competitiveness and reducing manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

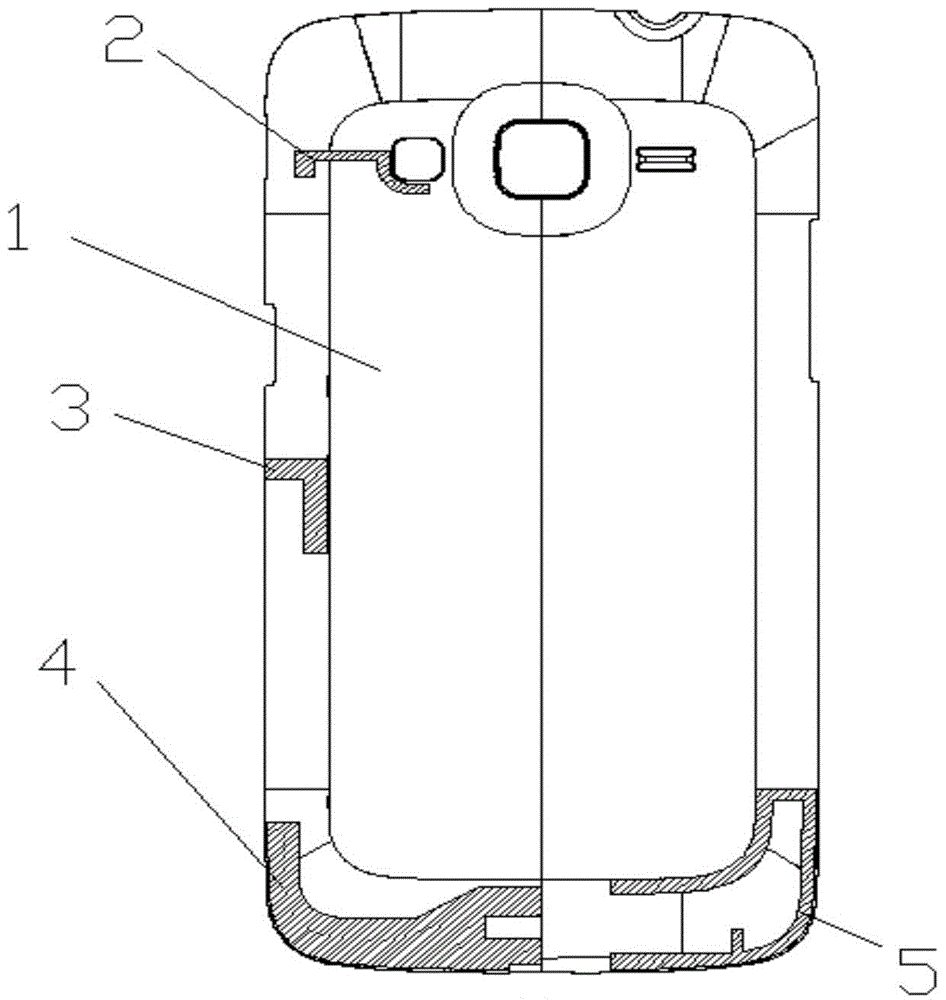

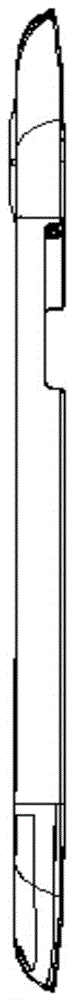

[0016] The manufacturing method of the electronic product shell of the present embodiment is: provide one or more sets of mobile phone antennas that need to be assembled or printed on the plastic molding mold on the surface, reserve a groove of corresponding depth at the antenna forming position, and process the antenna that needs to be assembled or printed. On the surface of the plastic product or in the groove of the inner wall, the surface is currently sprayed; the spraying process is: primer + intermediate paint 1 + intermediate paint 2 + intermediate paint 3 + top coat. Cancel the production process that requires sandblasting during the spraying process.

[0017] Its specific process steps include:

[0018] 1. The injection mold is designed in 3D drawing: the design plan is: firstly, the installation position of the antenna should be designed according to the function of the antenna. The design of the antenna should be far away from the main part of the battery, and the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com