Quick-wetting carboxylic acid copolymer thickening agent and preparation method thereof

A technology of carboxylic acid copolymers and thickeners, which is applied in the field of high molecular polymers. It can solve the problems of destroying the permanent viscosity of polymers, loss, storage or transportation inconvenience, and achieve excellent wetting effect, stable reaction, and particle size. Effects with a small distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

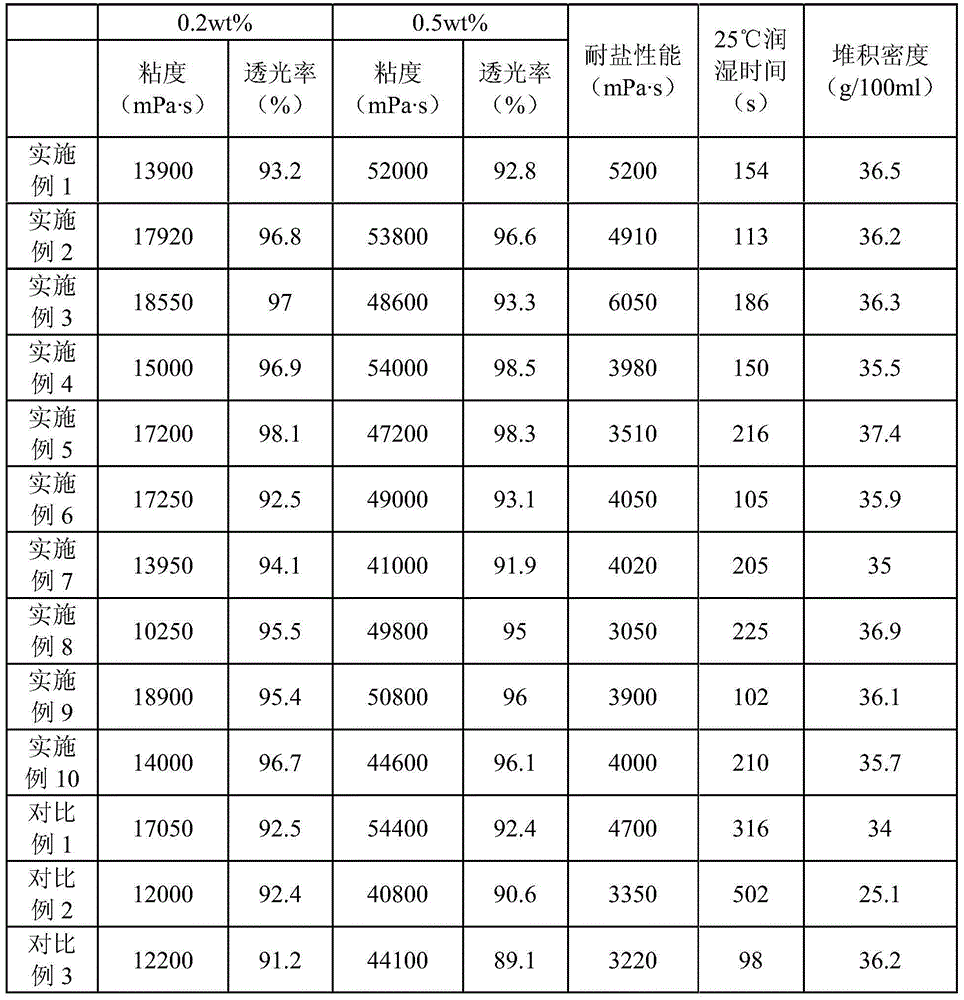

Examples

Embodiment 1

[0046] Step 1: Add 330g of cyclohexane, 15g of acrylic acid, 0.6g of lauryl methacrylate, 0.5g of sucrose allyl ether, 0.9g of polyoxyethylene 30 dipolyhydroxystearate into a 1000ml reactor, under nitrogen protection Stir at low temperature until the dispersion is uniform, then raise the temperature to 50°C, and add 0.05 g of acetylcyclohexylsulfonyl peroxide at one time. After about 15 minutes, the solution became cloudy and a white precipitate was formed.

[0047]Step 2: After continuing to react for 30 minutes, add 150g ethyl acetate, 72g acrylic acid, 3.3g lauryl methacrylate, 1.5g sucrose allyl ether, 2g polyoxyethylene 30 dimer A mixture of hydroxystearate and 0.21g of acetylcyclohexylsulfonyl peroxide was added dropwise for 3.5 hours.

[0048] Step 3: After the dropwise addition, add 0.02g of acetylcyclohexylsulfonyl peroxide and rinse the reactants remaining on the container wall with 15g of cyclohexane into the reaction kettle. After 30 minutes of heat preservation,...

Embodiment 2

[0051] Step 1: Add 330g cyclohexane, 15g ethyl acetate, 15g acrylic acid, 0.6g lauryl methacrylate, 0.5g sucrose allyl ether, 0.9g polyoxyethylene 30 dipolyhydroxystearic acid into a 1000ml reactor Esters were stirred under nitrogen protection until uniformly dispersed, then heated to 50°C, and 0.05 g of acetylcyclohexylsulfonyl peroxide was added at one time. After about 15 minutes, the solution became cloudy and a white precipitate was formed.

[0052] Step 2: After continuing to react for 30 minutes, add 135g ethyl acetate, 72g acrylic acid, 3.3g lauryl methacrylate, 1.5g sucrose allyl ether, 2g polyoxyethylene 30 dimer A mixture of hydroxystearate and 0.21g of acetylcyclohexylsulfonyl peroxide was added dropwise for 3.5 hours.

[0053] Step 3: After the dropwise addition, add 0.02g of acetylcyclohexylsulfonyl peroxide and rinse the reactants remaining on the container wall with 15g of cyclohexane into the reaction kettle. After 30 minutes of heat preservation, the temper...

Embodiment 3

[0056] Step 1: Add 330g cyclohexane, 54g ethyl acetate, 15g acrylic acid, 0.6g acrylate stearate, 0.5g pentaerythritol triallyl ether, 0.9g polyoxyethylene 30 dipolyhydroxystearin into a 1000ml reactor Ester, stirred under the protection of nitrogen until uniformly dispersed, then warmed up to 50°C, and 0.04g of di-n-propyl peroxydicarbonate was added at one time. After about 15 minutes, the solution became cloudy and a white precipitate was formed.

[0057] Step 2: After continuing to react for 30 minutes, add 96g ethyl acetate, 72g acrylic acid, 3.3g acrylate stearate, 1.5g sucrose allyl ether, 2g polyoxyethylene 30 dimer The mixture of hydroxystearate and 0.3g di-n-propyl peroxydicarbonate is added dropwise for 3.5h.

[0058] Step 3: Add 0.02 g of di-n-propyl peroxydicarbonate after the dropwise addition, and rinse the reactants remaining on the container wall with 15 g of cyclohexane into the reaction kettle. After 30 minutes of heat preservation, the temperature was rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com