Isopyrazam and tetraconazole bactericidal composition and application thereof

A technology of pyraclostrobin and tetrafluconazole, which is applied in application, bactericide, biocide, etc., can solve the problems of no products, achieve short wetting time, reduce the cost of medication, and improve the effect of bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

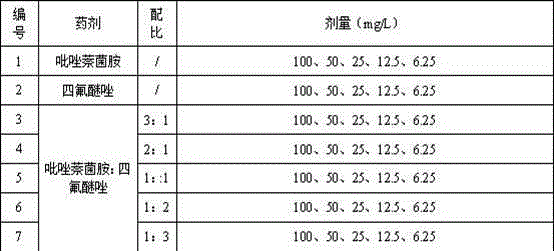

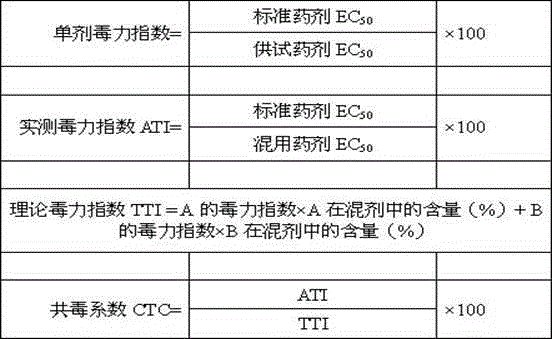

Method used

Image

Examples

Embodiment 1

[0045] The active ingredient is 15% pyraclostrobin Tetrafluconazole aqueous emulsion

[0046] Pyrafenafil (92%) 109kg, Tetrafluconazole (95%) 53 kg, Calcium dodecylbenzenesulfonate (emulsifier) 40 kg, Styrylphenyl polyoxyethylene ether (emulsifier) 45kg, methyl oleate 100kg (solvent), xylene 100kg (solvent), water to make up. During production, first add part of the solvent oil into the reaction kettle, then add the remaining solvent oil of the original drug and emulsifier in turn, stir at 2000 rpm for 30 minutes, after fully dissolving, transfer to the shearing kettle, add water at 3000 rpm The product was obtained by shearing in rpm for 30 minutes.

Embodiment 2

[0048] The active ingredient is 10% pyraclostrobin Tetrafluconazole aqueous emulsion

[0049] Pyrafenafil (92%) 55kg, Tetrafluconazole (95%) 53kg, Calcium dodecylbenzenesulfonate (emulsifier) 40 kg, Styrylphenyl polyoxyethylene ether (emulsifier) 45kg , methyl oleate 100kg (solvent), xylene 100kg (solvent), water to make up. During production, first add part of the solvent oil into the reaction kettle, then add the remaining solvent oil of the original drug and emulsifier in turn, stir at 2000 rpm for 30 minutes, after fully dissolving, transfer to the shearing kettle, add water at 3000 rpm The product was obtained by shearing in rpm for 30 minutes.

Embodiment 3

[0051] The active ingredient is 55% pyraclostrobin Tetrafluconazole water dispersible granules

[0052] Pyrafenapyr (92%) 544kg, Tetrafluconazole (95%) 53kg, Modified terminal olefin sulfonate (dispersant) 48kg, Polycarboxylate (dispersant) 40kg, Starch (filler) 100kg, Kaolin (filler) topping. During production, the raw materials are mixed and then pulverized by fluidized bed jet crushing equipment. The pulverized intermediates are put into fluidized bed granulation and drying equipment, and granules are made according to the operation requirements of the equipment. After drying, they are sieved to obtain processed products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com