Softener composition as well as preparation method and application of softener composition

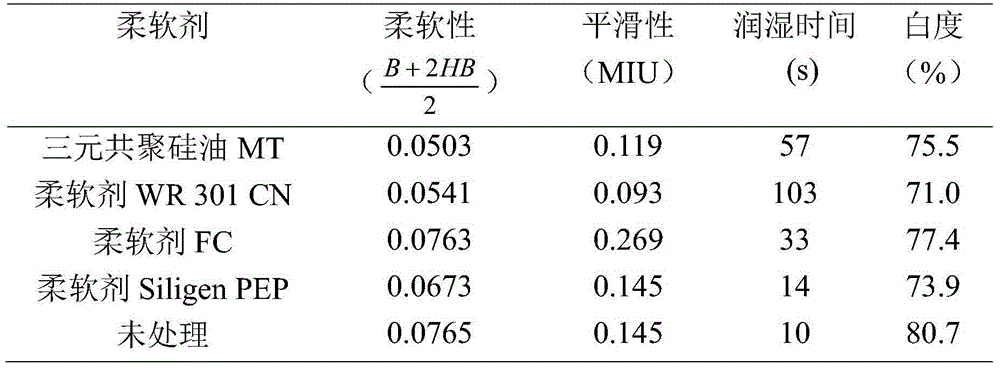

A technology of composition and softener, which is applied in the field of softener composition and its preparation, can solve the problems of unsatisfactory hydrophilicity and poor smooth hand feeling, and achieve shortened wetting time, improved smoothness, and good hydrophilicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative Embodiment 4~6

[0078] Compounding test of terpolymeric silicone oil MT and amino silicone oil Rodorsil21650, mix the two components uniformly according to the ratio listed in Table 4, add water to obtain a finishing solution with a concentration (non-volatile content) of 21g / L, and then treat the cotton For fabrics, the indicators of the finished products are determined, see Table 4. The stability test results of each finishing solution are shown in Table 5.

[0079] Table 4 Amino silicone oil Rodorsil21650 / terpolymerized silicone oil MT compound finishing product performance

[0080]

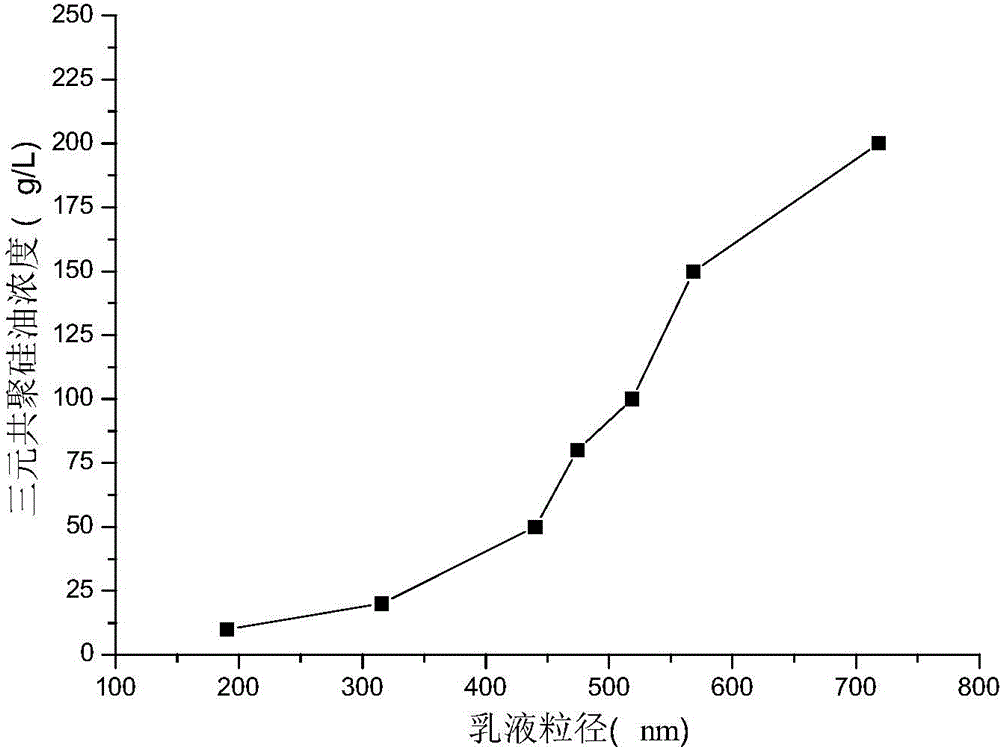

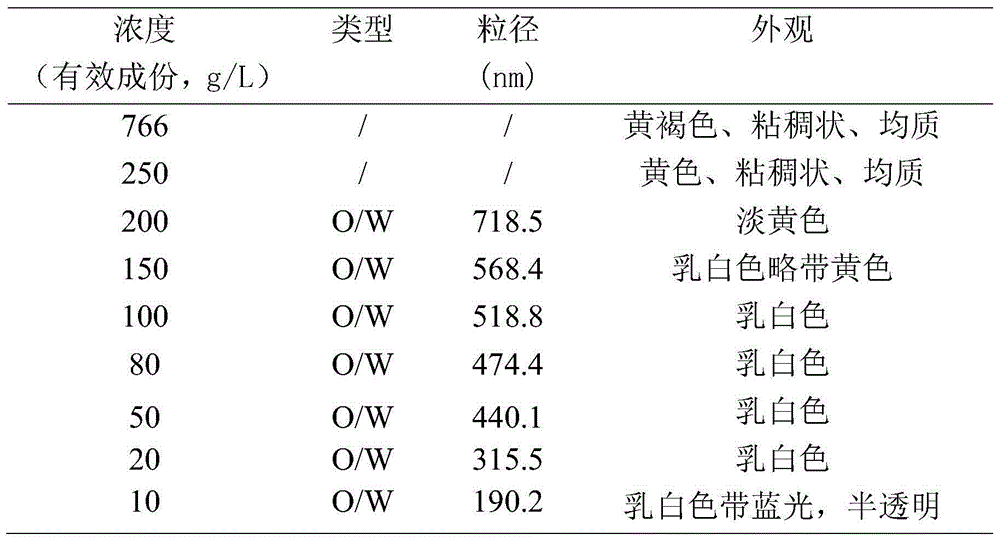

[0081] The data in Table 4 show that the particle size of the compound finishing solution decreases in the order listed. The softness of the finishing product is the best at the ratio of 10 / 90; the smoothness is the best at the ratio of 50 / 50, which is related to the smoothness of the amino silicone oil Rodorsil21650.

[0082] Manual evaluation, the order of softness and smoothness of the finishing produ...

Embodiment 4~9

[0095] According to the ratio listed in Table 7, mix Lutensol XP50 and terpolymerized silicone oil MT evenly to make an emulsion, and then compound it with amino silicone oil Rodorsil21650 (its quality is 1 / 9 of terpolymerized silicone oil MT). Cotton fabrics were treated with a finishing solution with a compound concentration of 21 g / L (non-volatile matter content), and the particle size of the finishing solution and properties of the finished product were measured, as shown in Table 7. The stability of the finishing solution is shown in Table 8. It can be seen from the data in Table 7 that when the amount of Lutensol XP50 is greater than or equal to 50%, the particle size of the finishing solution is less than 50nm. The softness of the finishing product is the best when the dosage is 10%; the smoothness is the best when the dosage is 50% and 100%, and the dosage is slightly lower when the dosage is 30% and 70%. The dosage of 100% is the shortest, which is close to that of un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com