Method for regenerating and prevulcanizing hydrogenation catalysts

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst regeneration/reactivation, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of high energy consumption and long production cycle, and achieve simple equipment and high sulfur retention , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

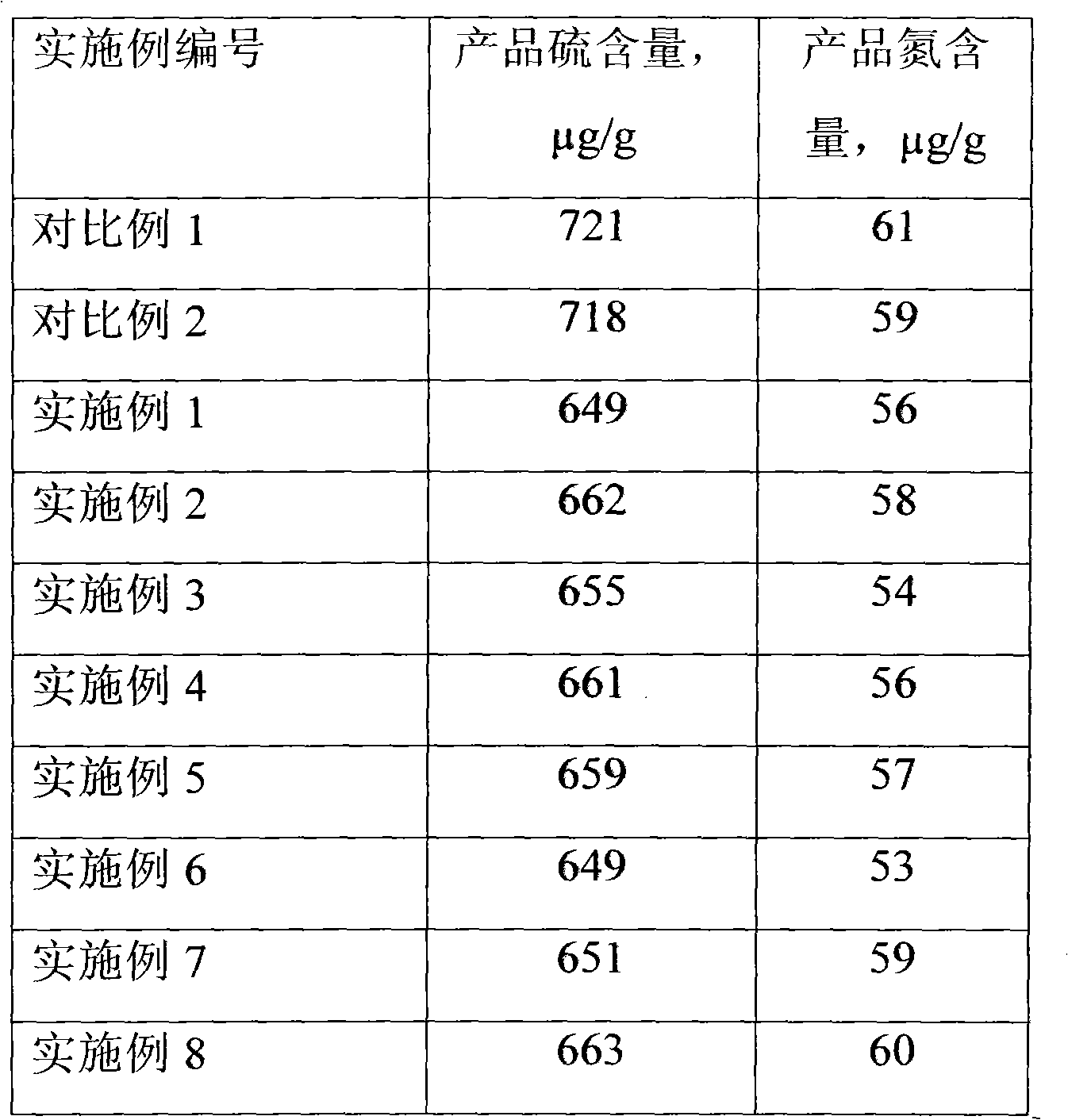

Embodiment 1

[0038] The amount of deactivated hydrotreating catalyst FH-DS is 100 grams, which is regenerated in an air atmosphere. Roast at a constant temperature of 280°C for 3 hours, then raise the temperature to 480°C for 3 hours, then lower the temperature to 180°C. With 20g organic solvent (organic solvent is coking kerosene fraction), the ratio of carbon number 9~12 in the organic solvent is not less than 50%, elemental sulfur 10g and 5g (NH 4 ) 2 S mixing, heat treatment at 150°C. Then the mixed liquid was impregnated with the catalyst and treated at 180° C. for 3 hours, and then cooled down to room temperature. The activity evaluation was carried out, and the catalyst activity results are shown in Table 2.

Embodiment 2

[0040] The amount of deactivated hydrotreating catalyst FH-DS is 100 grams, which is regenerated in an air atmosphere. Roast at a constant temperature of 320°C for 4 hours, then raise the temperature to 500°C and bake for 4 hours, then lower the temperature to 200°C. With 30g organic solvent (organic solvent is coking kerosene fraction), the ratio of carbon number 9~12 in the organic solvent is not less than 50%, elemental sulfur 12g and 6g (NH 4 ) 2 S mixing, heat treatment at 150°C. Then the mixed liquid was impregnated with the catalyst, and treated at 200° C. for 6 hours, and then cooled down to room temperature. The activity evaluation was carried out, and the catalyst activity results are shown in Table 2.

Embodiment 3

[0042] The amount of deactivated hydrotreating catalyst FH-DS is 100 grams, which is regenerated in an air atmosphere. Roast at a constant temperature of 300°C for 3 hours, then raise the temperature to 500°C and bake for 3 hours, then lower the temperature to 150°C. With 20g organic solvent (organic solvent is coking kerosene fraction), the ratio of carbon number 9~12 in the organic solvent is not less than 50%, elemental sulfur 10g and 5g (NH 4 ) 2 S mixing, heat treatment at 135°C. Then the mixed liquid was impregnated with the catalyst, and treated at 150° C. for 6 hours, and then cooled down to room temperature. The activity evaluation was carried out, and the catalyst activity results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com