Micro-premixing combustion chamber used for natural gas turbine and applied to wet air circulation

A technology for gas turbines and combustion chambers, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., to achieve the effects of reducing nitrogen oxide emissions, improving mixing uniformity, and improving ignition and flame transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

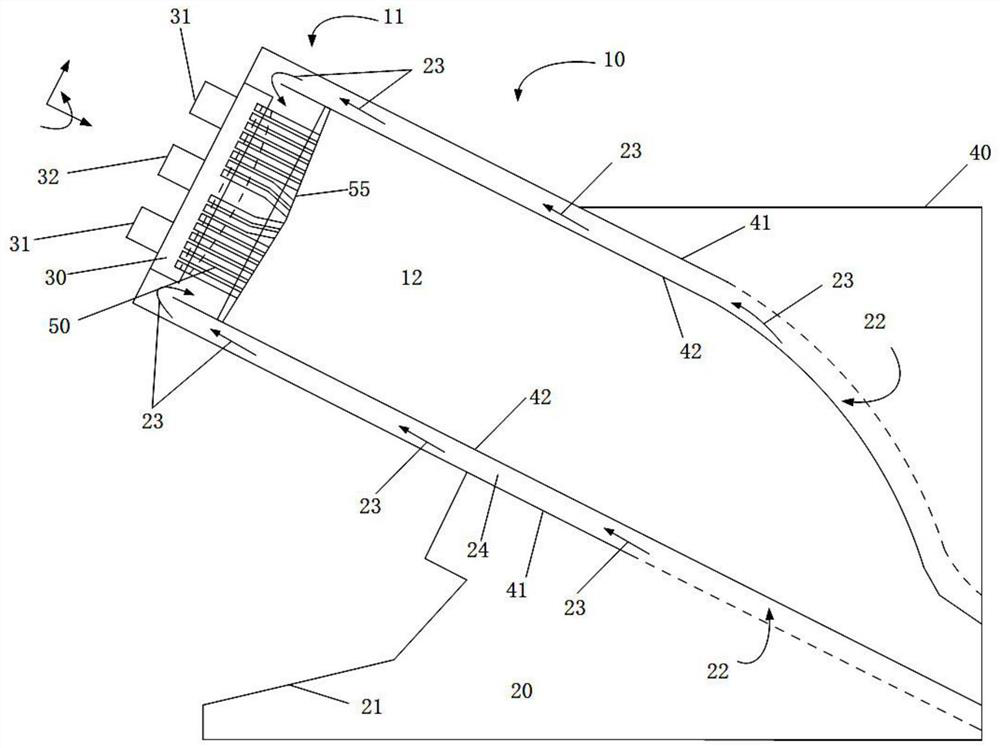

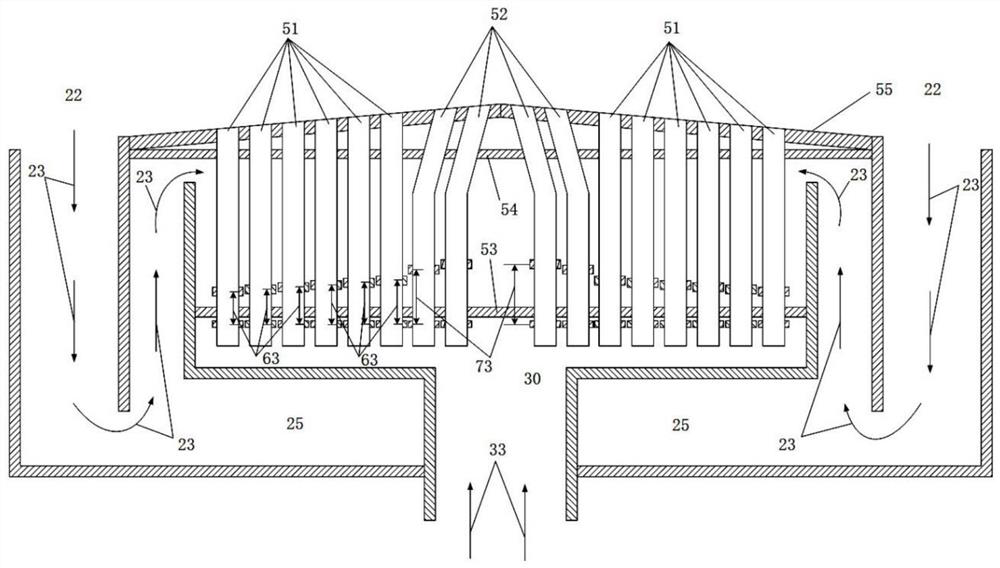

[0071] The present disclosure provides a micro-premix combustor of a natural gas gas turbine applied to wet air circulation, so as to alleviate the low expandability of the nozzle of the burner unit in the prior art, the uneven mixing of fuel and air, and flashback, spontaneous combustion and heat during operation. Acoustic vibration and other problems, while also alleviating the problem of high nitrogen oxide emissions.

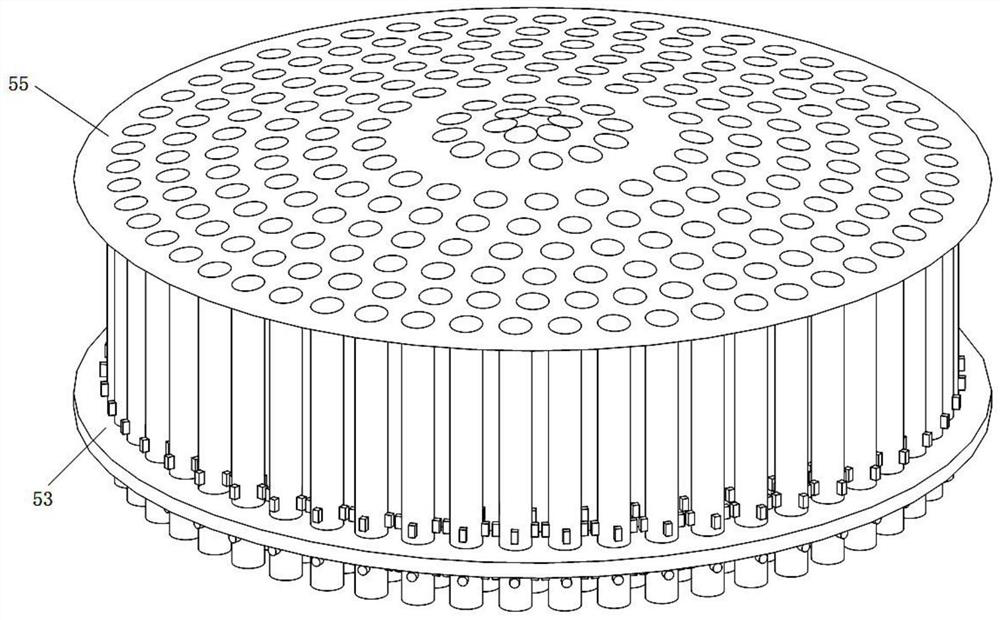

[0072] The present disclosure provides a natural gas gas turbine micro-premix combustion chamber applied to wet air circulation. The micro-premix combustion chamber includes: a burner body, which is arranged at the head of the combustion chamber, and is divided into a main nozzle area and a central duty nozzle area; The inlet is set at the bottom of the burner, and the air comes from the outlet of the upstream compressor; the air chamber, wrapped by the gas turbine casing, communicates with the gap channel formed by the combustion chamber liner and the flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com