Environment-friendly thermal insulation damping coating and preparation method thereof

A kind of damping coating and environment-friendly technology, applied in the direction of coating, etc., can solve the problems of difficult compatibility, unstable coating performance, poor flexibility, etc., and achieve excellent heat insulation and damping performance, moderate hard drying time, and moderate surface drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

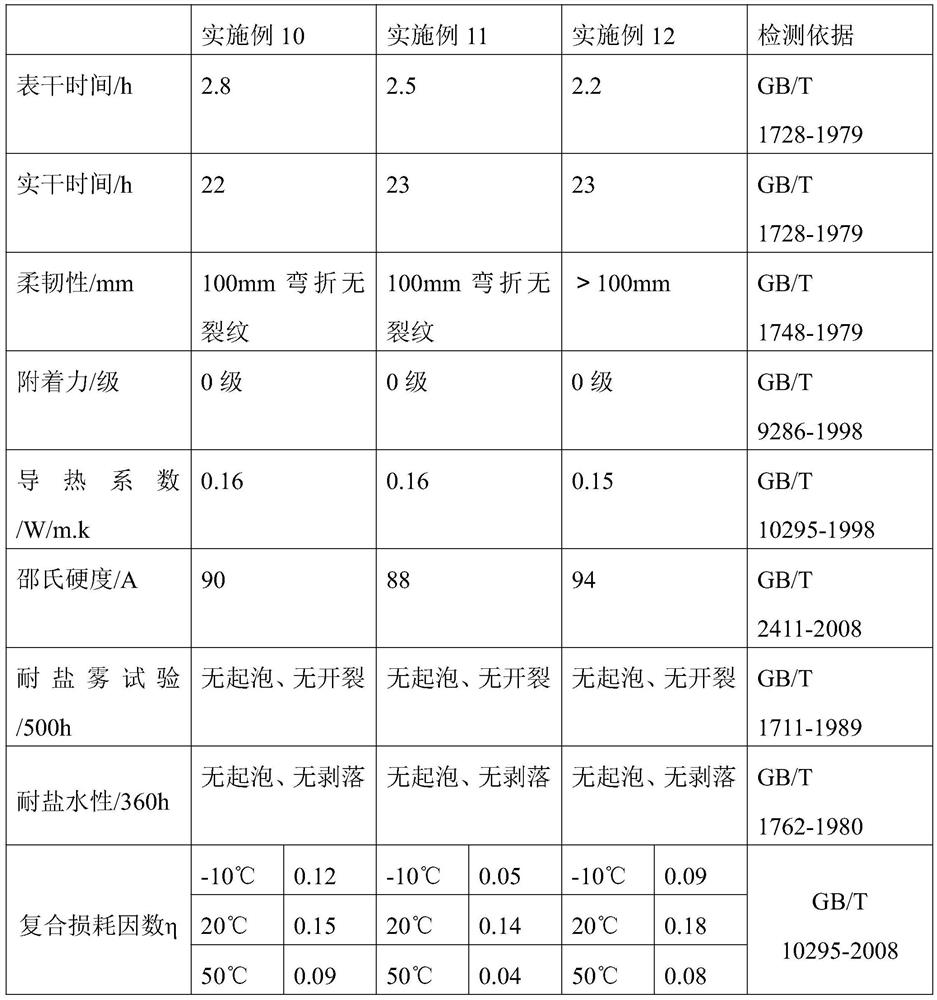

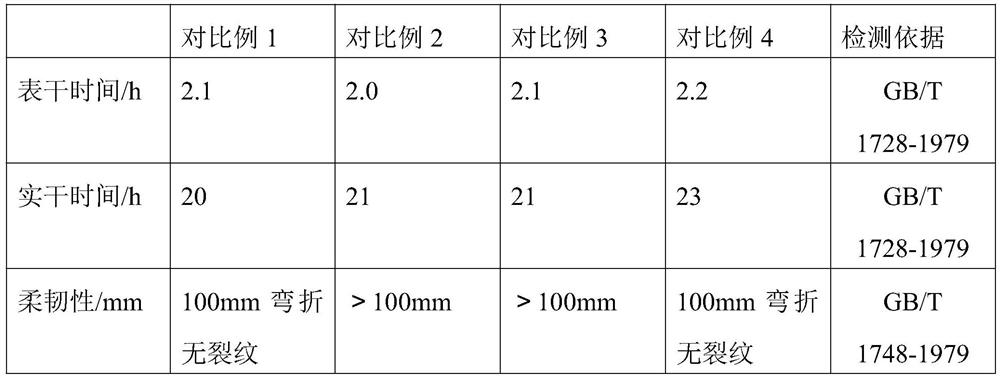

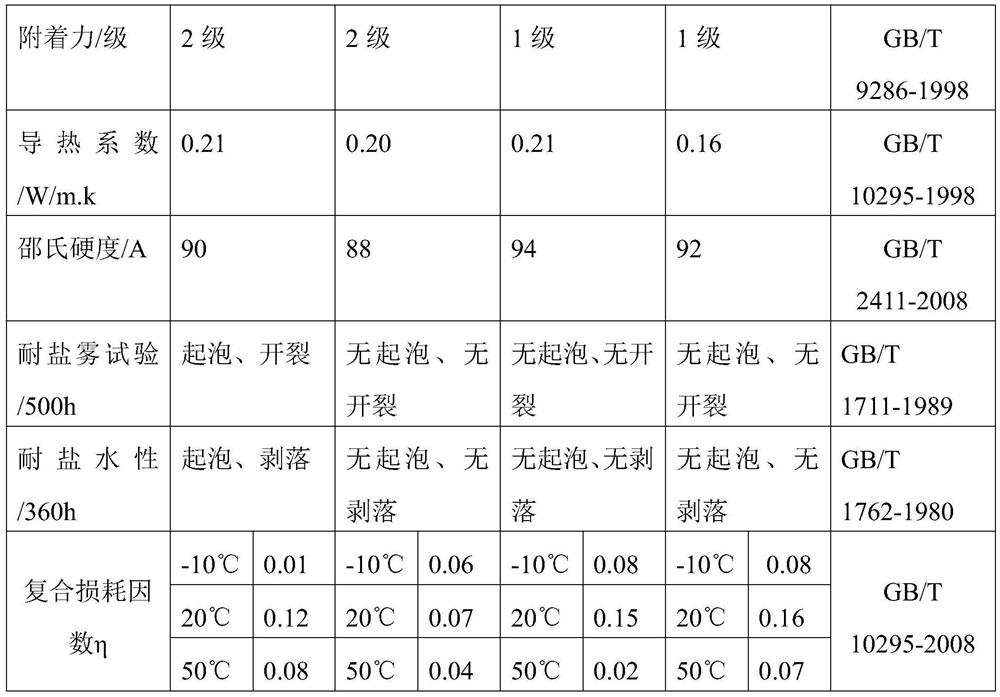

Examples

Embodiment 1

[0083] The preparation of flexible acrylic emulsion comprises the following steps:

[0084] ① The monomer butyl acrylate 110kg, isobutyl acrylate 350kg, ethyl methacrylate 10kg, acrylic acid 50kg and emulsifier polyoxyethylene octylphenol ether-1010kg, sodium lauryl sulfate 5kg, deionized water 300kg and Add 2kg of ammonium persulfate into the reactor, stir rapidly for 30 minutes until completely emulsified to obtain a pre-emulsion, and set aside;

[0085] ②Put 418.5kg of pre-emulsion into the reaction kettle, add 139.5kg of deionized water, stir and mix well, then raise the temperature to 65°C, react for 30 minutes, add the remaining pre-emulsifier (418.5kg) dropwise at this temperature After the dropwise addition, continue for 2 hours, cool down to room temperature, add sodium bicarbonate to adjust the pH to 6, and obtain a flexible acrylic emulsion. The glass transition temperature is -24°C as detected by DSC.

Embodiment 2

[0087] The preparation of flexible acrylic emulsion comprises the following steps:

[0088] ① The monomer butyl acrylate 50kg, isobutyl acrylate 250kg, ethyl methacrylate 50kg, acrylic acid 50kg and emulsifier polyoxyethylene octylphenol ether-1050kg, sodium lauryl sulfate 15kg, deionized water 400kg and Add 3kg of ammonium persulfate into the reactor, stir rapidly for 60 minutes until completely emulsified, and obtain a pre-emulsion for subsequent use;

[0089] ②Put 434kg of pre-emulsion into the reaction kettle, add 144.7kg of deionized water, stir and mix well, then heat up to 75°C, and react for 45 minutes, add the remaining pre-emulsifier (434kg) dropwise at this temperature, drop Continue for 3 hours after the addition, cool down to room temperature, add sodium bicarbonate to adjust the pH to 8, and obtain a flexible acrylic emulsion. The glass transition temperature is -15°C as detected by DSC.

Embodiment 3

[0091] The preparation of flexible acrylic emulsion comprises the following steps:

[0092] ① The monomer butyl acrylate 100kg, isobutyl acrylate 300kg, ethyl methacrylate 30kg, acrylic acid 80kg and emulsifier polyoxyethylene octylphenol ether-1040kg, sodium lauryl sulfate 10kg, deionized water 360kg and Add 2.5 kg of ammonium persulfate into the reactor, stir rapidly for 40 minutes until completely emulsified, and obtain a pre-emulsion, which is set aside;

[0093] ②Put 461.25kg of pre-emulsion into the reaction kettle, add 153.75kg of deionized water, stir and mix well, then raise the temperature to 70°C, and after reacting for 40 minutes, add the remaining pre-emulsifier (461.25kg) dropwise at this temperature After the dropwise addition, continue for 2.5 hours, cool down to room temperature, add sodium bicarbonate to adjust the pH to 7, and obtain a flexible acrylic emulsion. The glass transition temperature is -20°C as detected by DSC.

[0094] The remaining flexible ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com