Synthesis method and application of silane-terminated polyether

A technology of silane-terminated polyether and synthesis method, which is applied in the direction of polyether adhesives, adhesive types, adhesives, etc., can solve the problems of high reactivity, easy gelation, complicated procedures, etc., and achieve mild reaction conditions , surface drying time is moderate, and the synthesis steps are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

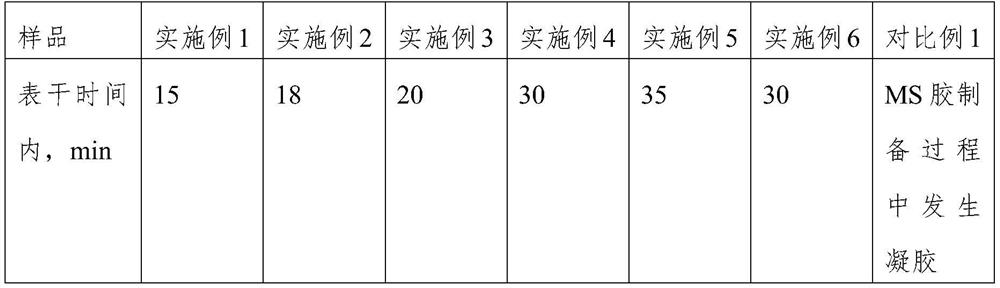

Examples

Embodiment 1

[0022] This embodiment provides a kind of silane-terminated polyether, and its synthetic method comprises the following steps:

[0023] Under the protection of nitrogen, add 5.3g methyl methacrylate, 100g molecular weight 4000PPG, 0.043g 2,5-di-tert-butylhydroquinone into the three-necked flask, react at 80°C to slight reflux, and collect by-product methanol by distillation , continue to heat up the unreacted methyl methacrylate, and continue to heat up until there is basically no distillate to obtain an unsaturated double bond modified polyether, and then add 10.1g of aminopropyltrimethoxysilane to it, at 120-125 ° C React for 3 hours, lower the temperature of the oil pump to -0.8MPa, and remove unreacted aminopropyltrimethoxysilane in a vacuum to obtain a colorless to pale yellow transparent silane-terminated polyether.

Embodiment 2

[0025] This embodiment provides a kind of silane-terminated polyether, and its synthetic method comprises the following steps:

[0026] Under the protection of nitrogen, add 6.3g methyl methacrylate, 100g molecular weight 4000PPG, 0.006g 2,5-di-tert-butylhydroquinone into a three-necked flask, heat at 85°C until a slight reflux occurs, and distill to collect by-product methanol , slowly raising the temperature to 110°C to distill and recover the unreacted methyl methacrylate, and continuously raising the temperature until there is basically no distillate to obtain an unsaturated double bond modified polyether, and then adding 11.7g of aminopropyltrimethoxysilane to it, React at 125-130°C for 6 hours, lower the temperature of the oil pump to -0.8MPa, and remove unreacted aminopropyltrimethoxysilane in a vacuum to obtain a light yellow transparent silane-terminated polyether.

Embodiment 3

[0028] This embodiment provides a kind of silane-terminated polyether, and its synthetic method comprises the following steps:

[0029] Under nitrogen protection, add 7.0g methyl methacrylate, 100g molecular weight 4000PPG, 0.004g 2,5-di-tert-butylhydroquinone into a three-necked flask, heat at 90°C until a slight reflux occurs, and distill to collect the by-product methanol , slowly raising the temperature to 120°C to distill and recover the unreacted methyl methacrylate, and continuously raising the temperature until there is basically no distillate to obtain an unsaturated double bond modified polyether, and then add 13.5g of aminopropyltrimethoxysilane to it, React at 130-135°C for 8 hours, lower the temperature of the oil pump to -0.8MPa, and remove unreacted aminopropyltrimethoxysilane in a vacuum to obtain a light yellow transparent silane-terminated polyether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com