Sealant prime coat liquid and preparation method thereof

A technology of primer and sealant, applied in the field of sealant, can solve the problems of shrinkage of primer, self-performance decline, poor heat resistance of sealant, etc., to achieve good bonding performance and mechanical properties, moderate surface drying time , the effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

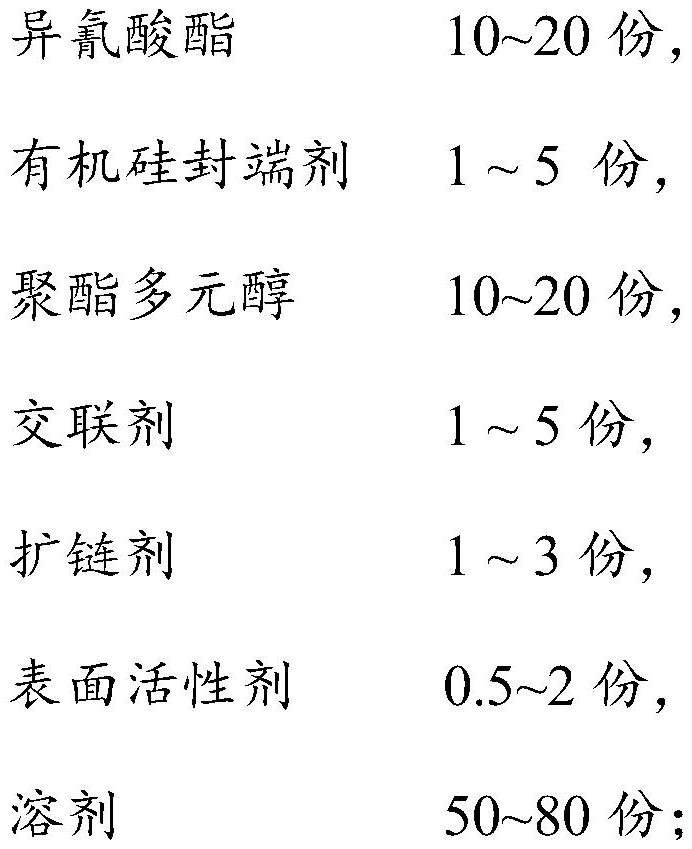

Method used

Image

Examples

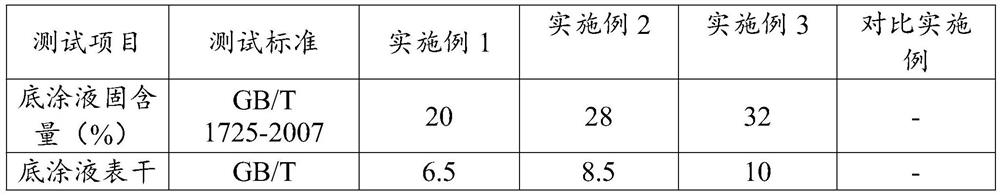

Embodiment 1

[0028] A sealant primer, comprising the following raw materials in parts by weight: 10 parts of isocyanate, 1 part of silicone blocking agent, 10 parts of polyester polyol, 1 part of crosslinking agent, 1 part of chain extender, surfactant 0.5 parts, 50 parts of solvent;

[0029] The polyester polyol is a mixture of polycarbonate diol and polyether diol, and the mass ratio is polycarbonate diol and polyether diol=1:1;

[0030] The isocyanate is toluene diisocyanate, and the organosilicon blocking agent is tetramethyldisiloxane;

[0031] The crosslinking agent is a mixture of methyltriacetoxysilane, polytriallyl isocyanurate, isocyanatotrimethoxysilane and aminosilane, and the mass ratio is methyltriacetoxysilane: poly Triallyl isocyanurate: isocyanate trimethoxysilane: aminosilane = 2:1:1:2;

[0032] The chain extender is diethylaminoethanol;

[0033] The surfactant is a mixture of amino silicone oil and alcohol modified silicone oil, and the mass ratio is amino silicone oi...

Embodiment 2

[0040] A sealant primer, comprising the following raw materials in parts by weight: 20 parts of isocyanate, 5 parts of silicone end-capping agent, 20 parts of polyester polyol, 5 parts of crosslinking agent, 3 parts of chain extender, surfactant 2 parts, 80 parts of solvent;

[0041] The polyester polyol is a mixture of polycarbonate diol and polyether triol, and the mass ratio is polycarbonate diol and polyether triol=1:1.5;

[0042] The isocyanate is toluene diisocyanate, and the organosilicon blocking agent is tetramethyldisiloxane;

[0043] The crosslinking agent is a mixture of methyltriacetoxysilane, polytriallyl isocyanurate, isocyanatotrimethoxysilane and aminosilane, and the mass ratio is methyltriacetoxysilane: poly Triallyl isocyanurate: isocyanate trimethoxysilane: aminosilane = 2:1:1:2;

[0044] The chain extender is diethylaminoethanol, N, N-dihydroxyaniline;

[0045] The surfactant is a mixture of amino silicone oil and alcohol modified silicone oil, and the ...

Embodiment 3

[0052] A sealant primer, comprising the following raw materials in parts by weight: 15 parts of isocyanate, 3 parts of silicone end-capping agent, 15 parts of polyester polyol, 3 parts of crosslinking agent, 2 parts of chain extender, surfactant 1.2 parts, 65 parts of solvent;

[0053] The polyester polyol is a mixture of polycarbonate diol and polyether diol, and the mass ratio is polycarbonate diol and polyether diol=1:1.2;

[0054] The isocyanate is toluene diisocyanate, and the organosilicon blocking agent is tetramethyldisiloxane;

[0055] The crosslinking agent is a mixture of methyltriacetoxysilane, polytriallyl isocyanurate, isocyanatotrimethoxysilane and aminosilane, and the mass ratio is methyltriacetoxysilane: poly Triallyl isocyanurate: isocyanate trimethoxysilane: aminosilane = 2:1:1:2;

[0056] The chain extender is diethylaminoethanol, N, N-dihydroxyaniline, trimethylolpropane;

[0057] The surfactant is a mixture of amino silicone oil and alcohol modified si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com