Novel LED and a high-power radiator of a radiating element

A heat dissipation device and high-power technology, which is applied in the field of heat dissipation of high-power heat dissipation devices, can solve the problems of limited heat dissipation space, large equivalent thermal resistance, and difficulty in increasing the heat dissipation of the device, and overcome the problems of small contact area, small equivalent thermal resistance of heat conduction, and The effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with the accompanying drawings.

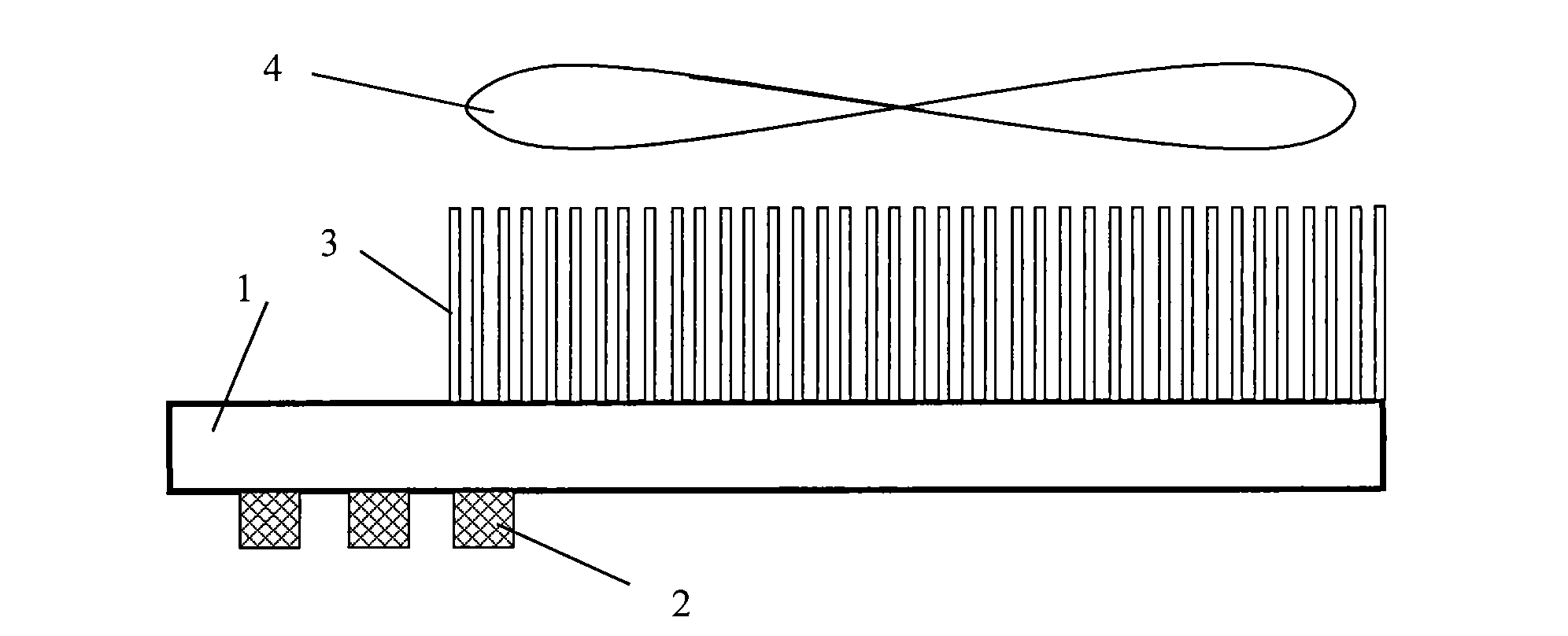

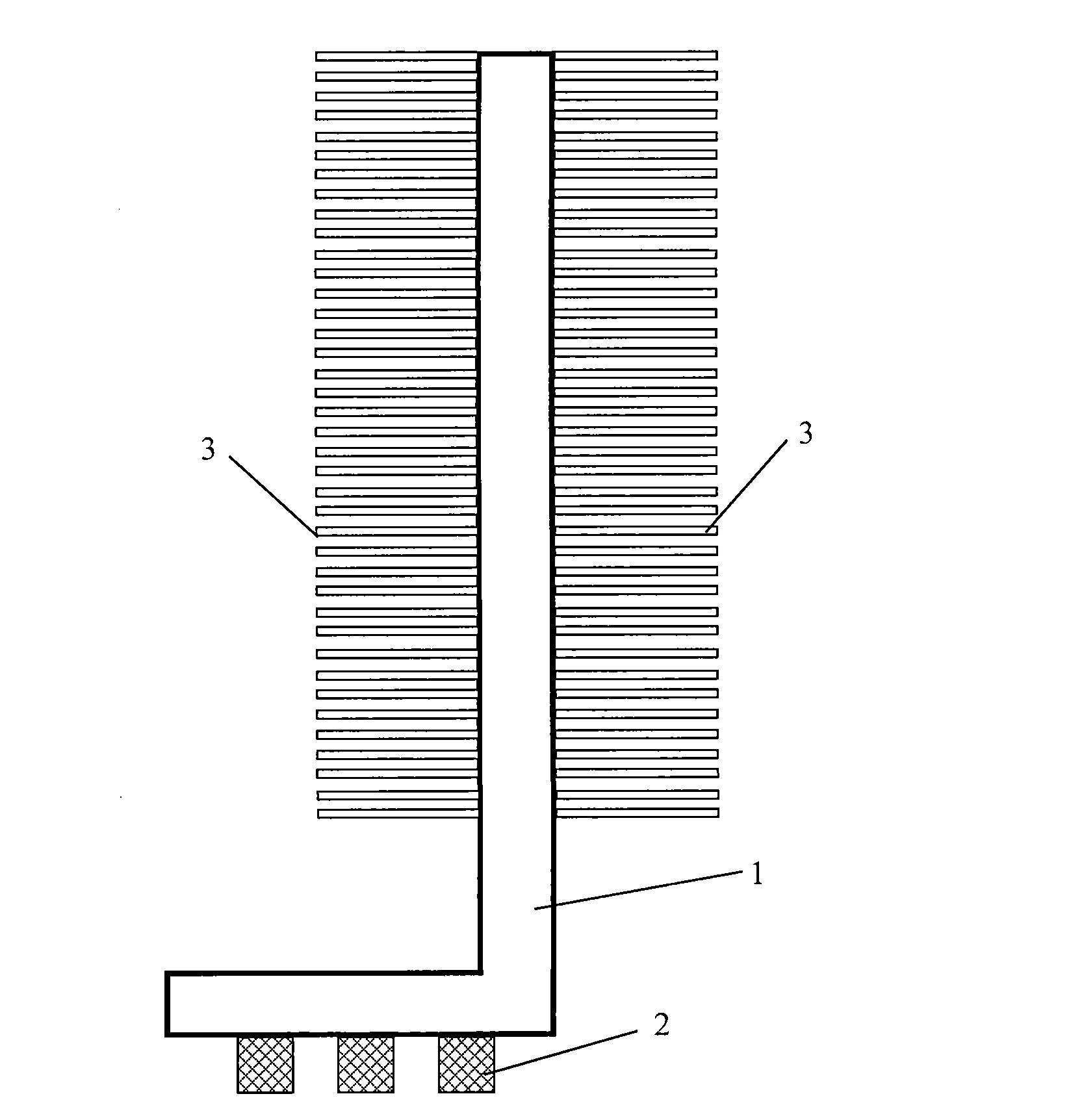

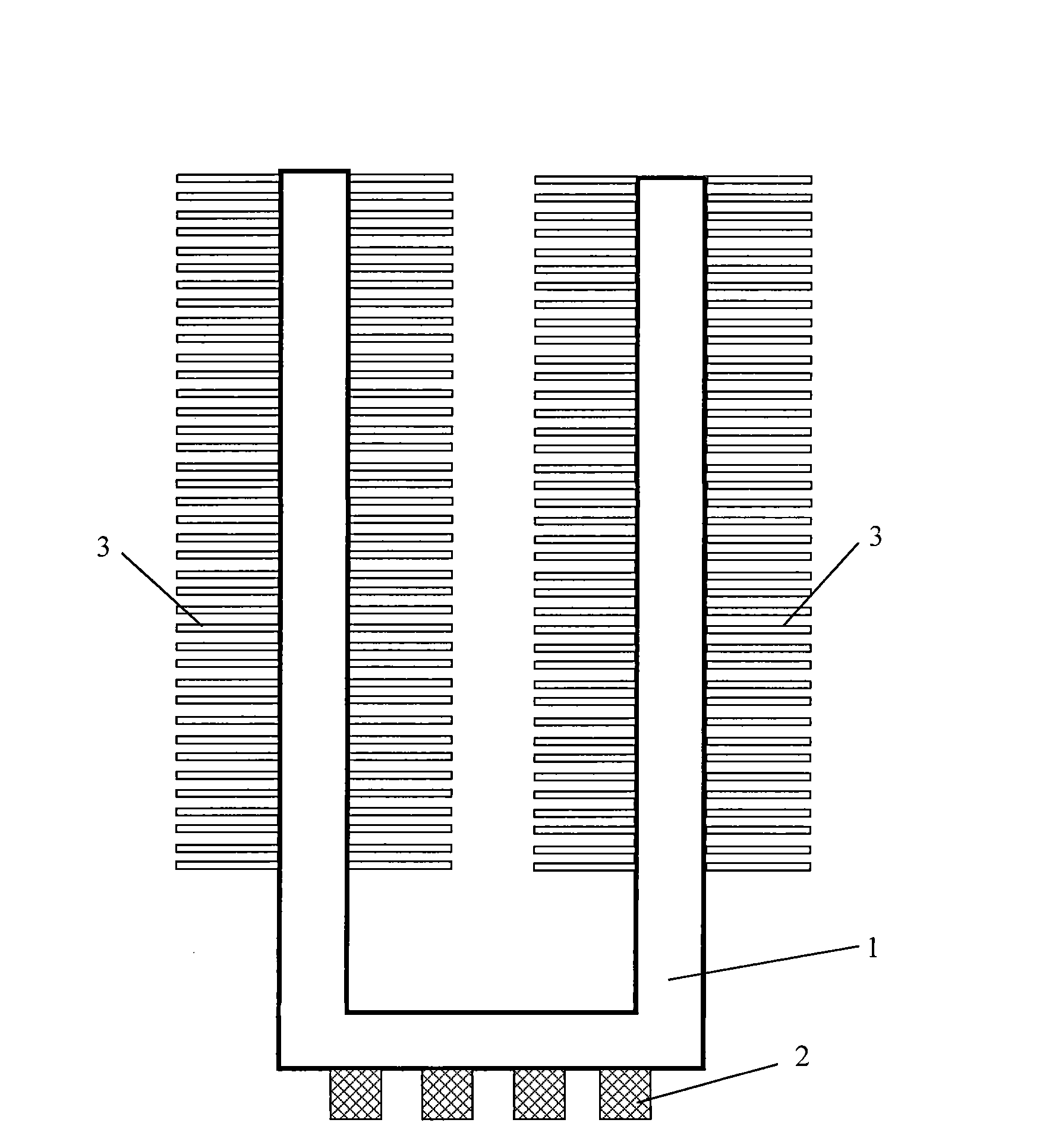

[0028] figure 1 It is a structural schematic diagram of the first preferred embodiment of the radiator of the new LED and high-power heat dissipation device of the present invention. The radiator of the novel LED and high-power heat dissipation device includes a flat heat pipe 1, and the flat heat pipe is a metal material that is extruded or stamped. Formed two or more through-hole array plate structures arranged side by side, taking into account the heating characteristics of the heating surface of LEDs and high-power heat dissipation devices, the structural characteristics of LED and high-power heat dissipation devices installation, and the influence of installation space and working environment factors, etc. The equivalent diameter of the through hole of a specific size is set based on various factors. For example, the operating temperature of the LED is usually within 120°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com