Evaporation type condenser system used for thermal power plant small steam turbine steam exhaust condensing

A technology of evaporative condenser and small steam turbine, which is applied in the field of evaporative condenser system and evaporative condensation, which can solve the problems of high operating cost, heavy operation and maintenance workload, and large area occupied by generator sets, and achieve heat exchange effect Good, the effect of controlling the floating water rate and low water quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

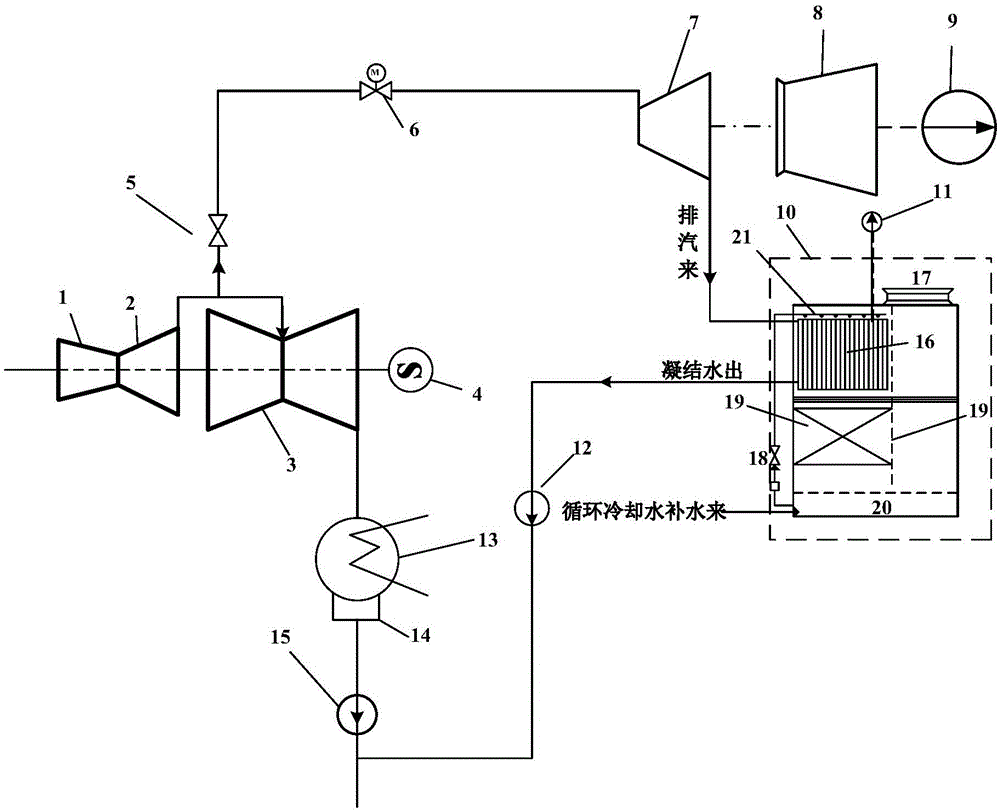

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , the present invention comprises the high-pressure cylinder 1, the medium-pressure cylinder 2, the low-pressure cylinder 3, the driving steam turbine 7 and the condenser 13 of the direct air-cooling unit; Type condenser 10, the condensed water outlet of the evaporative condenser 10 is connected to the condensed jellyfish pipe, and is returned to the main engine heat recovery system through the booster pump 12.

[0024] The evaporative condenser 10 includes a shell, and the inside of the shell is divided into left and right sides, and a water eliminator for realizing the separation of gas-liquid two-phase and controlling the floating water rate is arranged between the left and right sides of the shell. A tube-bundle or plate-plate heat exchanger 16 is arranged on the upper part of one side of the housing, and an axial flow fan 17 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com