Composite phase change material and its preparation method and building material

A technology for composite phase change materials and building materials, applied in the field of building materials, composite phase change materials and their preparation, can solve the problems of liquid leakage, strong subcooling, low heat storage and release efficiency, etc. The effect of heat and exotherm enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

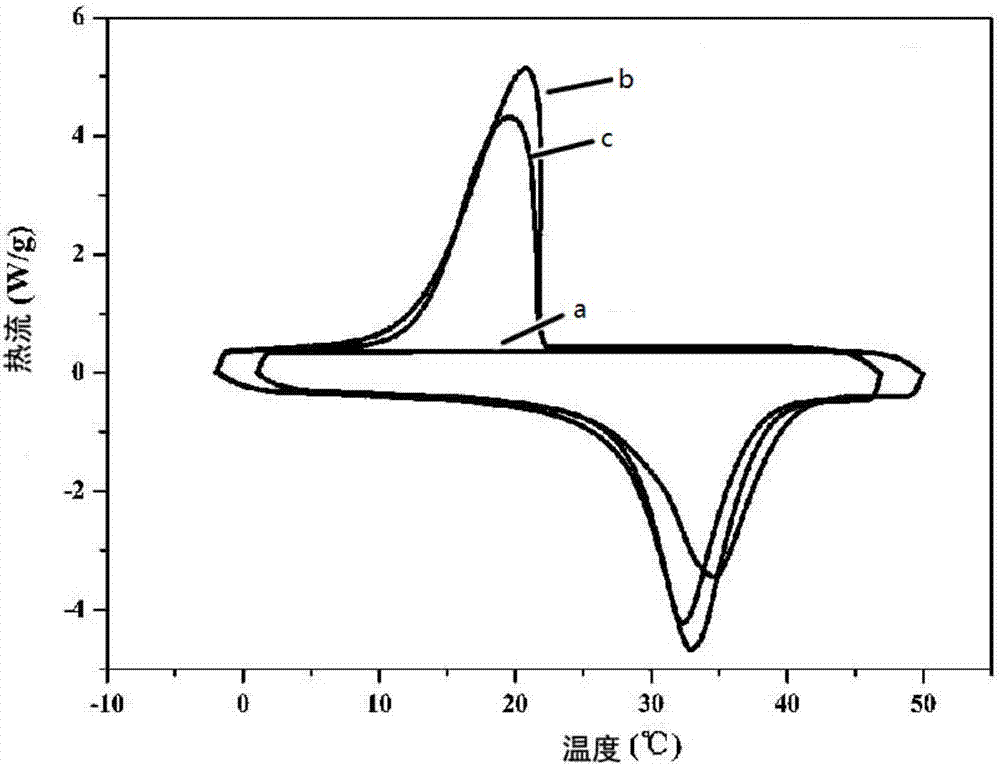

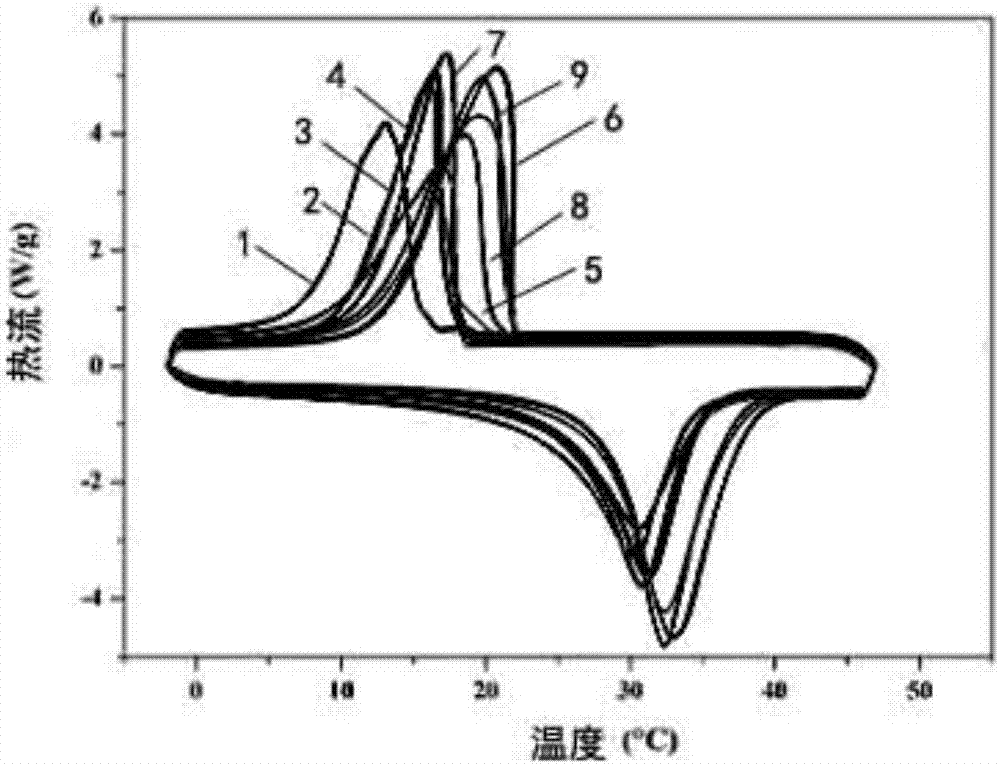

[0041] Weigh 4.3495g of distilled water and weigh 4.4705 grams of anhydrous calcium chloride. Since anhydrous calcium chloride has strong water absorption, it is quickly poured into the previously weighed distilled water to dissolve after the weighing is completed. While dissolving, 0.18 g of strontium chloride hexahydrate was added thereto. Finally, 1 g of expanded graphite (adsorption rate: 90%) was added to the above mixed solution, stirred with a glass rod for 10 min, and mixed evenly to obtain a composite phase change material.

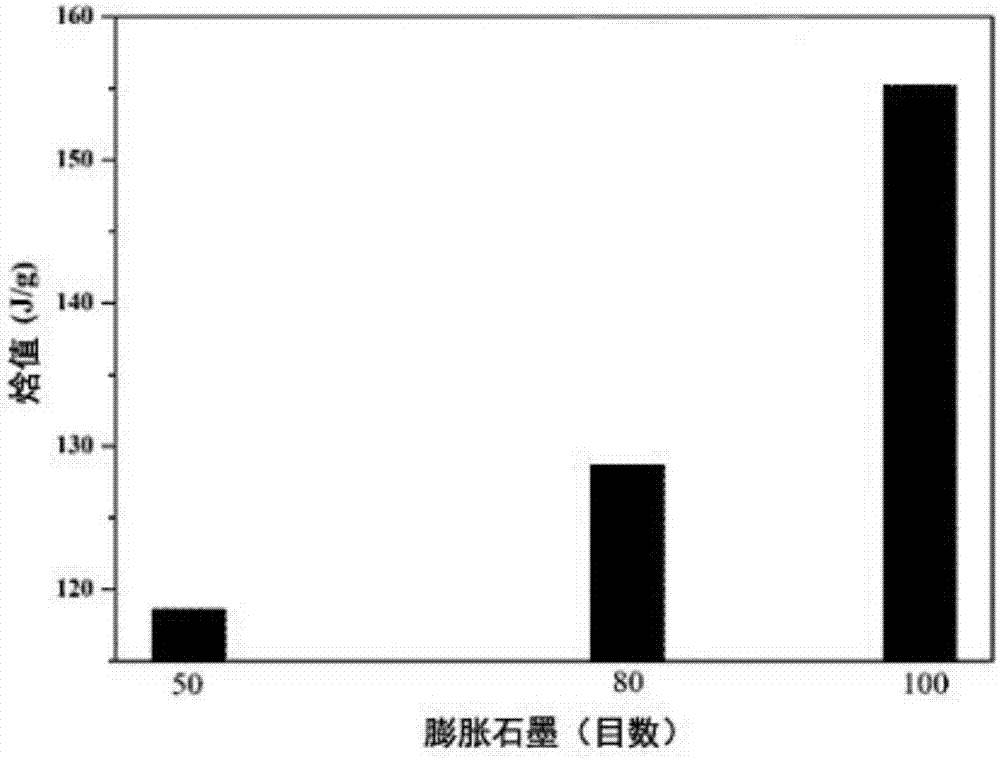

[0042] The preparation method of expanded graphite is as follows: unexpanded graphite of a certain size is obtained after being heated and expanded for a certain period of time under a certain heating power. The expanded graphite in Examples 1-9 were respectively prepared according to the parameter conditions shown in Table 1, and the corresponding phase transition temperature, phase transition enthalpy and thermal conductivity are also shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com