Early-strength CK anchoring agent and application thereof

An anchoring agent and curing agent technology, which is applied in the field of early-strength CK anchoring agent, can solve problems such as low final strength, roof and roadway collapse, and potential safety hazards in coal mines, and achieve rapid early strength development, improved safety factor, and high final strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

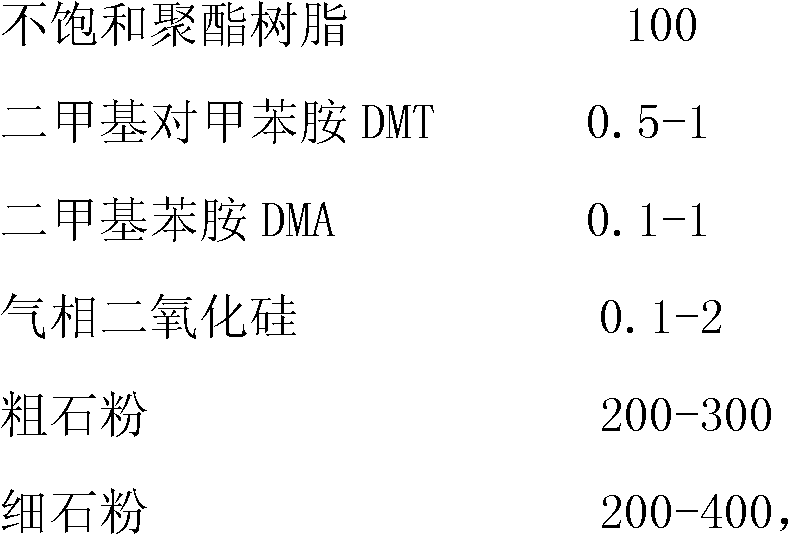

[0017] The gel time is 8-15 seconds. The CK fast anchoring agent includes resin cement and curing agent. The weight ratio of resin cement and curing agent is 100:4, and the weight parts of the raw materials of its resin cement and curing agent are:

[0018] (1) Resin cement

[0019]

[0020] (2) curing agent:

[0021]

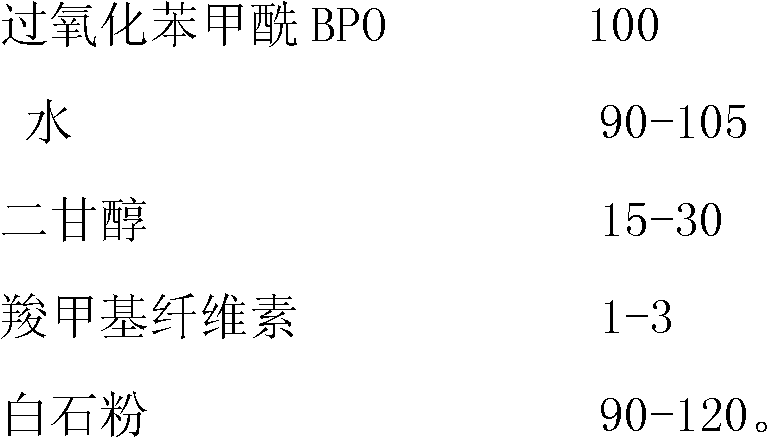

[0022] Example 2 gel time in 16-25 seconds CK fast anchoring agent, including resin cement and curing agent, the weight ratio of resin cement and curing agent is 100: 5, and the weight parts of the composition raw materials of its resin cement and curing agent are:

[0023] (1) Resin cement

[0024]

[0025] (2) curing agent:

[0026]

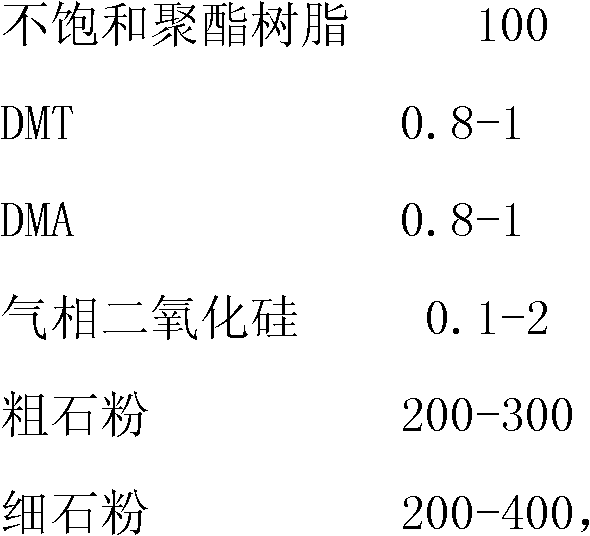

[0027] Example 3 The gel time is 26-40 seconds CK fast anchoring agent, including resin cement and curing agent, the weight ratio of resin cement and curing agent is 100: 6, and the weight parts of the composition raw materials of its resin cement and curing agent are:

[0028] (1) Resin cement

[0029]

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com