High-performance environment-friendly soft soil curing agent and preparation method thereof

A curing agent, high-performance technology, used in chemical instruments and methods, soil conditioning materials, organic fertilizers, etc., can solve the problems of high risk of shrinkage cracking, limited application scope, up to hundreds of dollars, etc., to speed up the curing reaction rate. , Improve crack resistance, good fiber reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

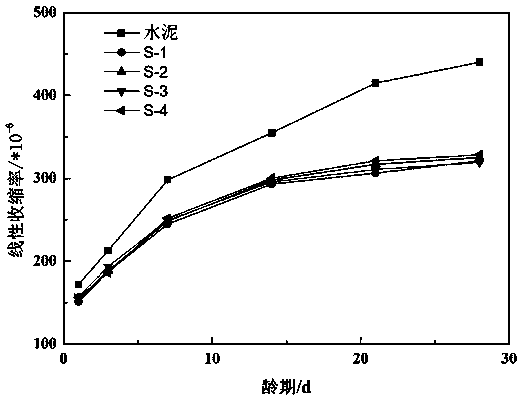

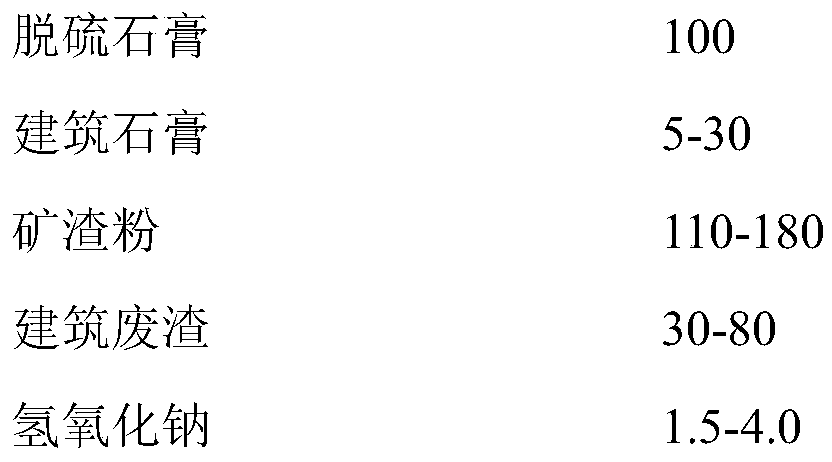

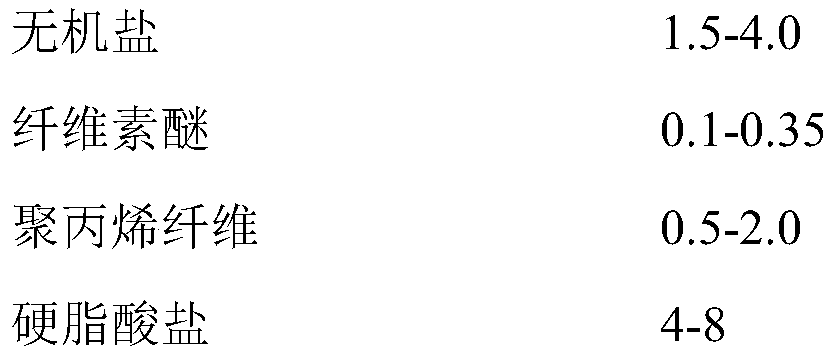

[0037]Example 1, a high-performance environment-friendly soft soil curing agent and its preparation method, according to the weight ratio of raw materials: desulfurization gypsum 100, α-hemihydrate gypsum 5, slag powder (S95:S105=60:40) 110, construction waste slag 80 , sodium hydroxide 1.5, inorganic salts (CaCl 2 : FeCl 3 =70:30) 1.5, cellulose ether 0.1, polypropylene fiber (10mm in length) 0.5, sodium stearate 4 Weigh the raw materials, first add slag powder, construction waste residue, sodium hydroxide and inorganic salts into the ball mill for powder Grinding modification, after grinding for 15 minutes, adding desulfurized gypsum and α-hemihydrate gypsum to the ball mill, grinding for 3 minutes, finally adding cellulose ether, polypropylene fiber and sodium stearate to the ball mill, grinding for 2 minutes, and obtaining The product of the present invention is denoted as S-1.

Embodiment 2

[0038] Example 2, a high-performance environment-friendly soft soil curing agent and its preparation method, according to the weight ratio of raw materials: desulfurization gypsum 100, α-hemihydrate gypsum 15, slag powder (S95:S105=70:30) 140, construction waste slag 60 , sodium hydroxide 2.5, inorganic salts (CaCl 2 : FeCl 3 =60:40) 2.0, cellulose ether 0.15, polypropylene fiber (8mm in length) 0.9, calcium stearate 5.5 Weigh the raw materials, first add slag powder, construction waste residue, sodium hydroxide and inorganic salts into the ball mill for powder Grinding modification, after grinding for 17 minutes, adding desulfurized gypsum and α-hemihydrate gypsum to the ball mill, grinding for 4 minutes, finally adding cellulose ether, polypropylene fiber and sodium stearate to the ball mill, grinding for 2 minutes, and obtaining The product of the present invention is denoted as S-2.

Embodiment 3

[0039] Example 3, a high-performance environment-friendly soft soil curing agent and its preparation method, according to the weight ratio of raw materials: desulfurization gypsum 100, β-hemihydrate gypsum 25, slag powder (S95:S105=80:20) 155, construction waste slag 45 , sodium hydroxide 3.0, inorganic salts (CaCl 2 : FeCl 3 =55:45) 2.5, cellulose ether 0.3, polypropylene fiber (8mm in length) 1.6, zinc stearate 6.5 Weigh the raw materials, first add slag powder, construction waste residue, sodium hydroxide and inorganic salt into the ball mill for powder Grinding modification, after grinding for 18 minutes, add desulfurized gypsum and β-hemihydrate gypsum to the ball mill, grind for 5 minutes, finally add cellulose ether, polypropylene fiber and sodium stearate to the ball mill, grind for 3 minutes, and obtain The product of the present invention is denoted as S-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com