Composite lightening material for well cementation, preparation method of composite lightening material, deep well composite cement paste and application of composite cement paste

A cement slurry, deep well technology, applied in wellbore/well components, chemical instruments and methods, earth-moving drilling, etc., can solve the problem of not giving the specific components of the reducing agent, the method of making the reducing agent, unsuitable for oil and gas wells, poor stability, etc. problem, to achieve the effect of simple and feasible production process, strong on-site operability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

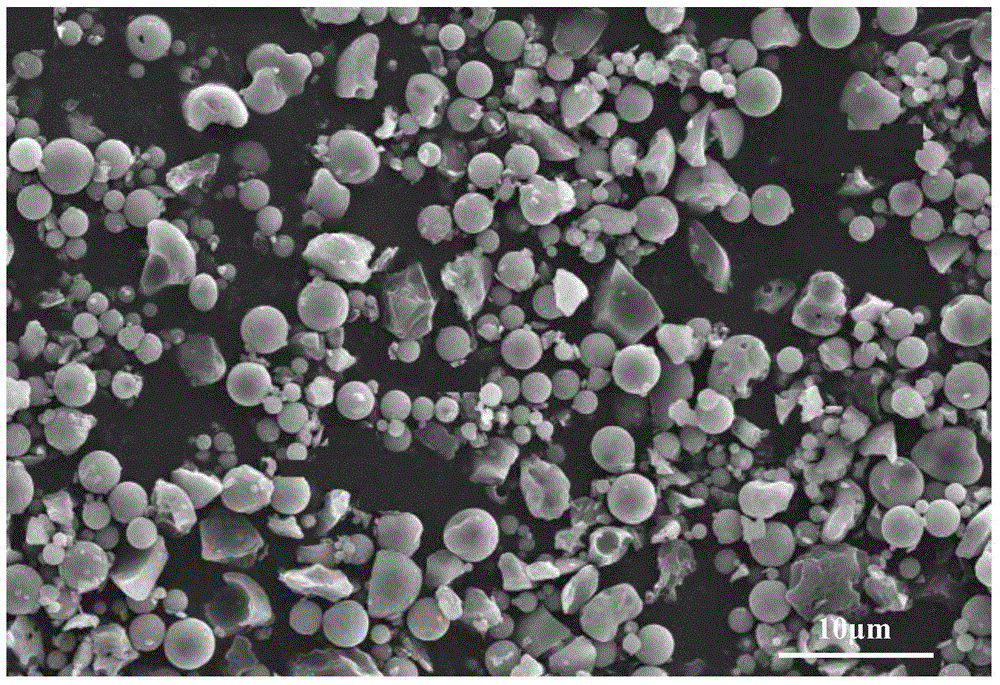

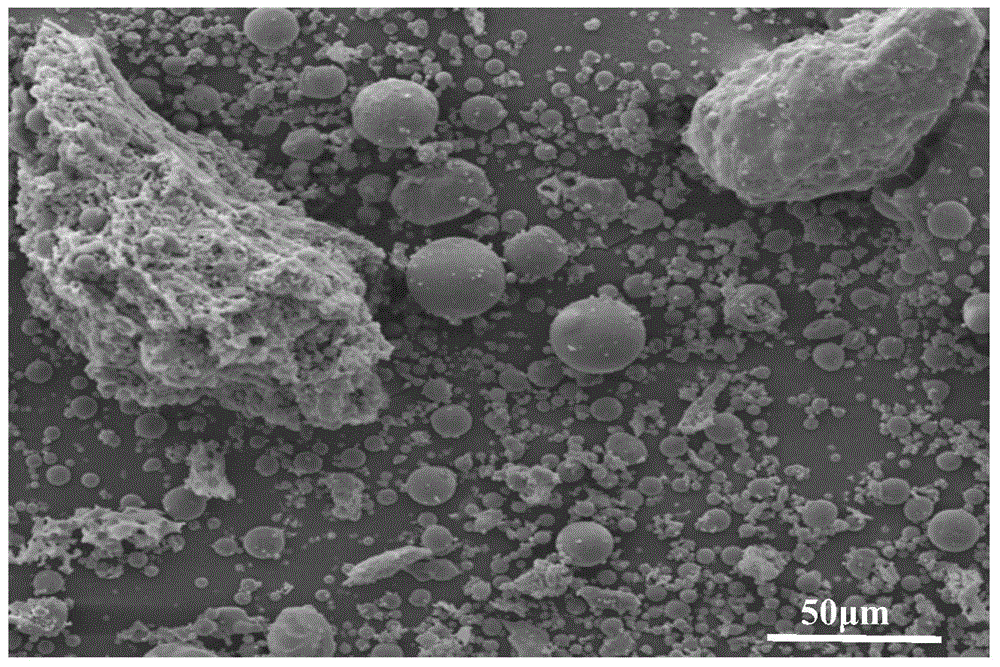

[0056] Preparation of modified fly ash:

[0057] Conventional fly ash was ball-milled in a suspension roller mill for 30 minutes, and then classified three times in a jet centrifugal superfine classifier according to the classification process to obtain different samples and test their performance, see Table 1.

[0058] Table 1 Fly ash samples and their properties

[0059]

Embodiment 1

[0061] The composite lightening material includes: 100 parts by weight of modified fly ash (sample number D4), 10 parts by weight of vermiculite (Sinopec Petroleum Engineering Technology Research Institute Oilfield Additive R&D Center) and 5 parts by weight of asbestos (Sinopec Petroleum Engineering Technology Research Institute Oilfield Additives R&D Center).

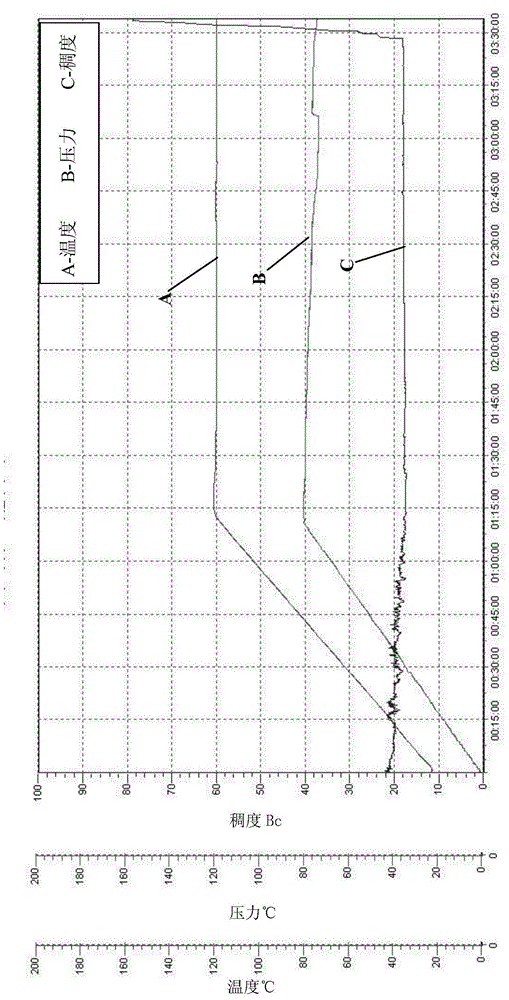

[0062] Deep well composite cement slurry: 100 parts by weight of Aksu G grade oil well cement, 1.5 parts by weight of stabilizer, 20 parts by weight of fluid loss reducer DZJ-Y, 2.0 parts by weight of early strength agent H, and 1.5 parts by weight of retarder DZH-2, adding 100 parts by weight of the composite lightening material of this embodiment, the liquid-solid weight ratio is 0.78.

[0063] Prepare cement slurry according to GB / T19139 standard (density 1.60g / cm 3 ), and carried out the settlement stability performance, thickening and compressive strength tests, the test results are shown in Table 2.

Embodiment 2

[0065] Composite lightening material: 100 parts by weight of modified fly ash (sample number D4), 12 parts by weight of vermiculite, and 6 parts by weight of asbestos.

[0066] Deep well composite cement slurry: 100 parts by weight of Aksu G grade oil well cement, 2.5 parts by weight of high temperature stabilizer, 20 parts by weight of anti-high temperature fluid loss reducing agent DZJ-Y, 2.0 parts by weight of early strength agent H, 1.5 parts by weight of Retarder DZH-2, add 120 parts by weight of the composite lightening material of this embodiment, and the liquid-solid ratio is 0.96.

[0067] Prepare cement slurry according to GB / T19139 standard (density 1.50g / cm 3 ), and carried out the settlement stability performance, thickening and compressive strength tests, the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com