Low-melting metal heat absorption solution

A low-melting-point metal and solution technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as damage to high-temperature objects or surrounding workpieces, hinder heat transfer between high-temperature objects and phase change materials, and damage to high-temperature objects. Enhance convective heat transfer and promote rapid heat absorption or release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

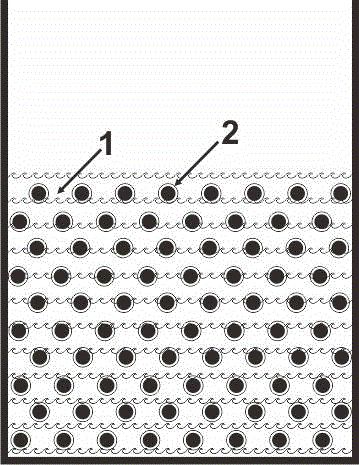

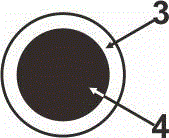

[0033] Example 1 demonstrates a typical application of a low-melting-point metal endothermic solution of the present invention. figure 1 It is a schematic diagram of the components of a low-melting-point metal endothermic solution dispersion system in the embodiment, figure 2 It is a schematic diagram of the components of phase change microcapsules in a low melting point metal endothermic solution in the embodiment. Among them: 1 is a dispersion medium, 2 is a phase change microcapsule, 3 is a wall material, and 4 is a low melting point metal.

[0034] A kind of low melting point metal endothermic solution of the present embodiment, dispersion medium is water, the wall material of phase change microcapsule is polystyrene, and core material is bismuth indium tin alloy (alloy mass fraction is: Bi 32.5%, 51% In , 16.5% Sn), the melting point of bismuth indium tin alloy is 60°C. Phase change microcapsules are made by in-situ polymerization. The mass fraction of phase change mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com