Two-stage compression air conditioning system with defrosting function

A technology for compressing air conditioners and two-stage compressors, which is applied to compressors with reversible cycles, compressors, lighting and heating equipment, etc. It can solve the problems of prolonging defrosting time, slow defrosting speed, and refrigerant entry, etc., to achieve Guaranteed comfort, fast heat release, and sufficient heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

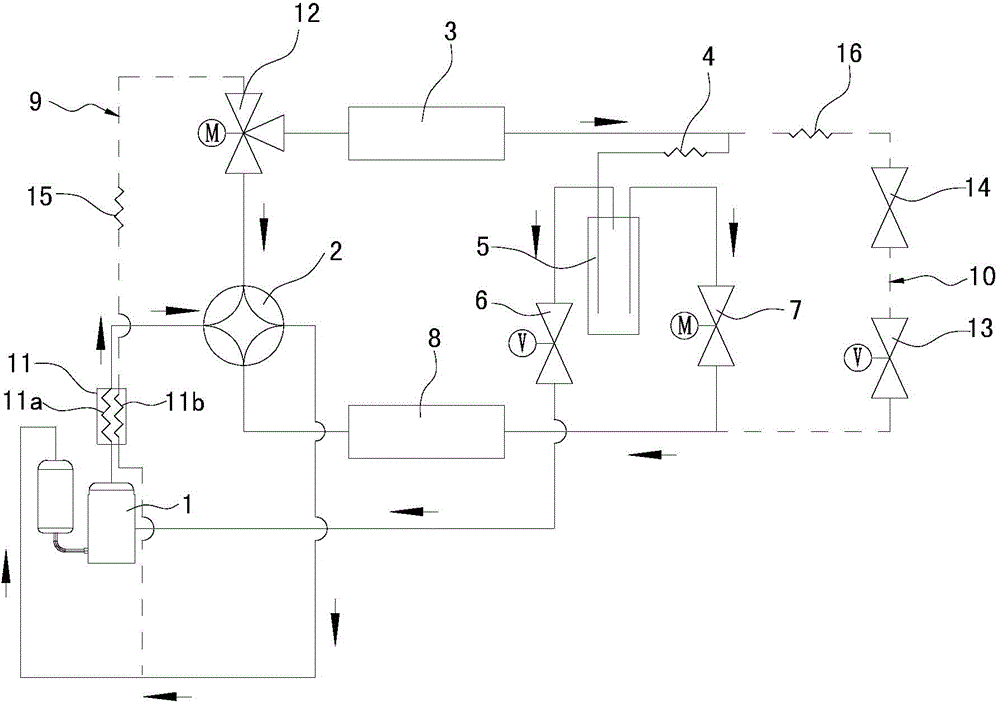

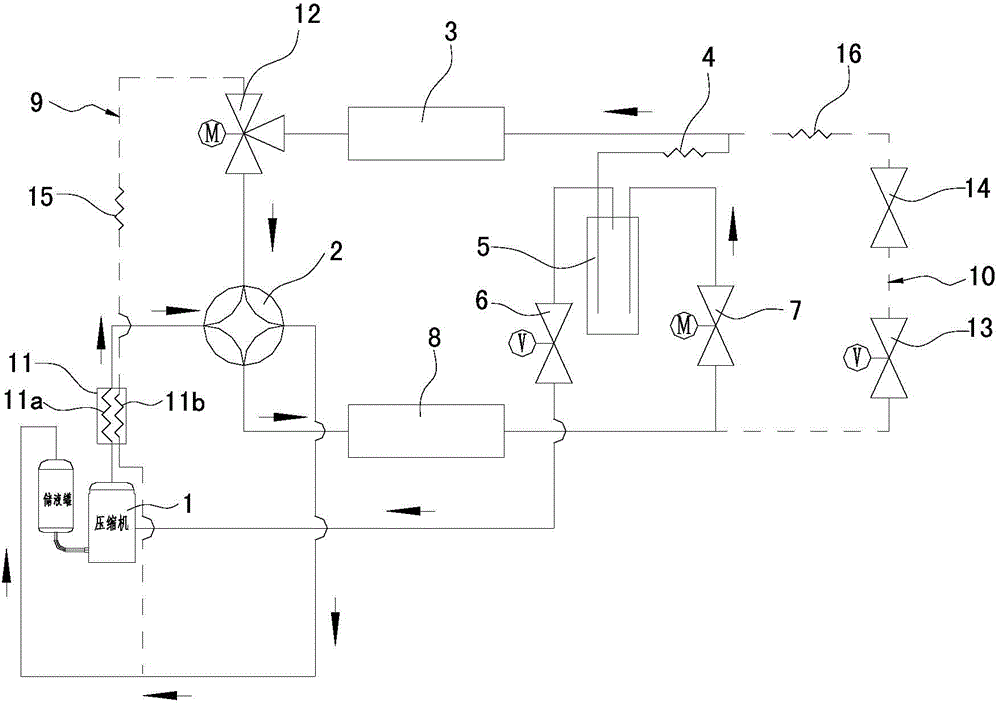

[0029] Such as Figure 1~3As shown, the two-stage compression air-conditioning system with defrosting function in this embodiment is the same as the existing two-stage compression air-conditioning system with defrosting function: both include a two-stage compressor 1 and a four-way reversing valve 2 , an outdoor heat exchanger 3, a first throttling device 4, a flash evaporator 5, a second throttling device 7 and an indoor heat exchanger 8, wherein the exhaust port and the suction port of the two-stage compressor 1 pass through the The four-way reversing valve 2 is connected to the first end of the outdoor heat exchanger 3 and the first end of the indoor heat exchanger 8, and the second end of the outdoor heat exchanger 3 passes through the first throttling device 4 is connected to the first interface of the flash evaporator 5, the second interface of the flash evaporator 5 is connected to the second end of the indoor heat exchanger 8 through the second throttling device 7, and...

Embodiment 2

[0040] Figure 4 Shown is a schematic diagram of a two-stage compression air-conditioning system with defrosting function in Embodiment 2 of the present invention. The difference from Embodiment 1 is that one end of the second bypass pipeline 10 is connected to the pipeline between the second end of the outdoor heat exchanger 3 and the first throttling device 4 , and the other end is connected to On the pipeline between the flasher 5 and the second throttling device 7 . During defrosting, after the refrigerant flows out of the indoor heat exchanger 8, it passes through the second throttling device 7 and enters the second bypass pipeline 10. At this time, the opening degree of the second throttling device 7 is the largest, and there is only a slight throttling of the refrigerant. flow effect.

Embodiment 3

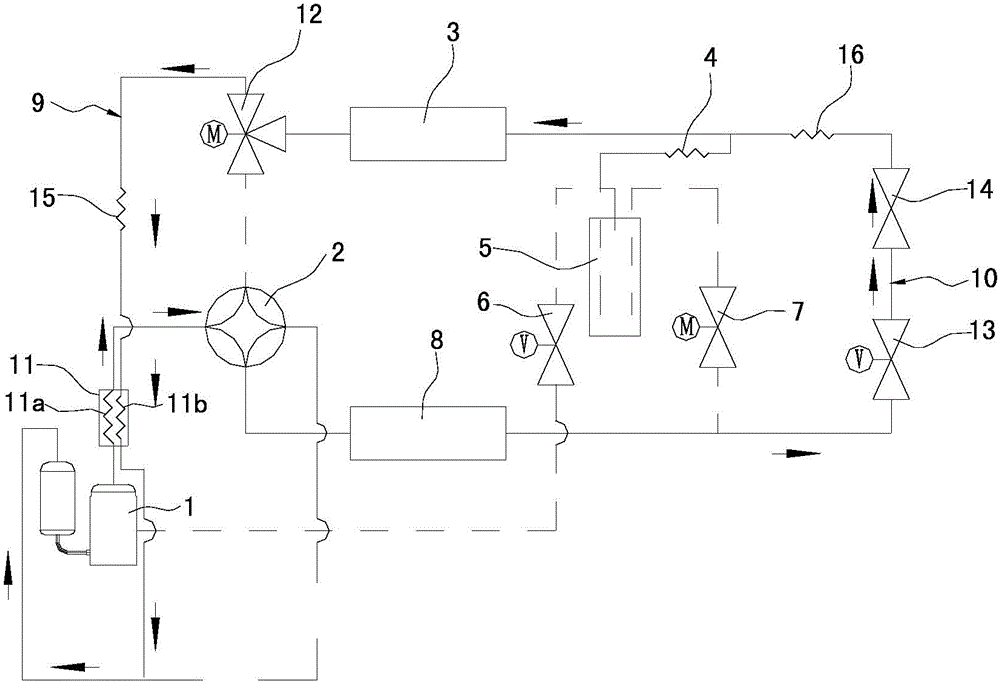

[0042] Figure 5 Shown is a schematic diagram of a two-stage compression air-conditioning system with defrosting function in Embodiment 2 of the present invention. The difference from Embodiment 1 is that the three-way valve 12 is arranged behind the four-way reversing valve 2, that is, the first port of the three-way valve 12 is connected to the four-way reversing valve 2 through a refrigerant pipe, and the The second port of the three-way valve 12 is connected to the suction port of the two-stage compressor 1 through a refrigerant pipe, and the third port of the three-way valve 12 is connected to one end of the first bypass pipe 9 through a refrigerant pipe. The other end of the first bypass pipeline 9 is connected to the pipeline between the second interface of the three-way valve 12 and the suction port of the two-stage compressor 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com