Method for preparing high-performance heat-generating agent

A technology for exothermic agents and raw materials, applied in the field of preparation of high-performance exothermic agents, can solve problems such as affecting the heating effect, and achieve the effects of increasing the calorific value, promoting combustion, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

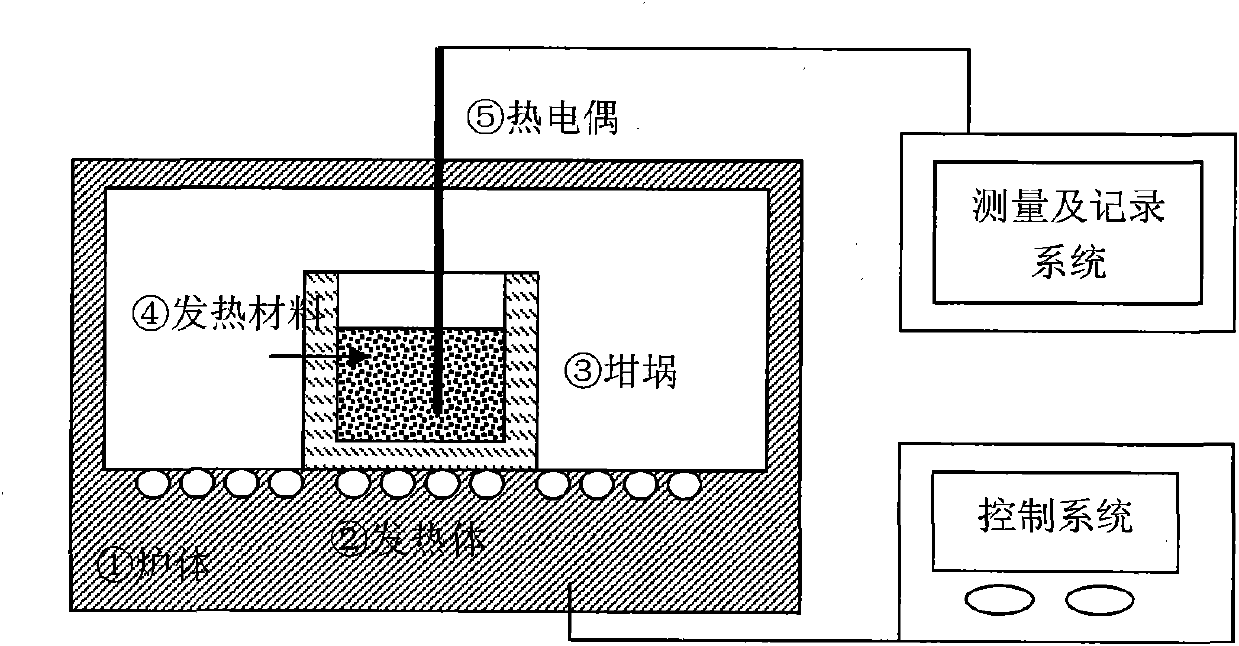

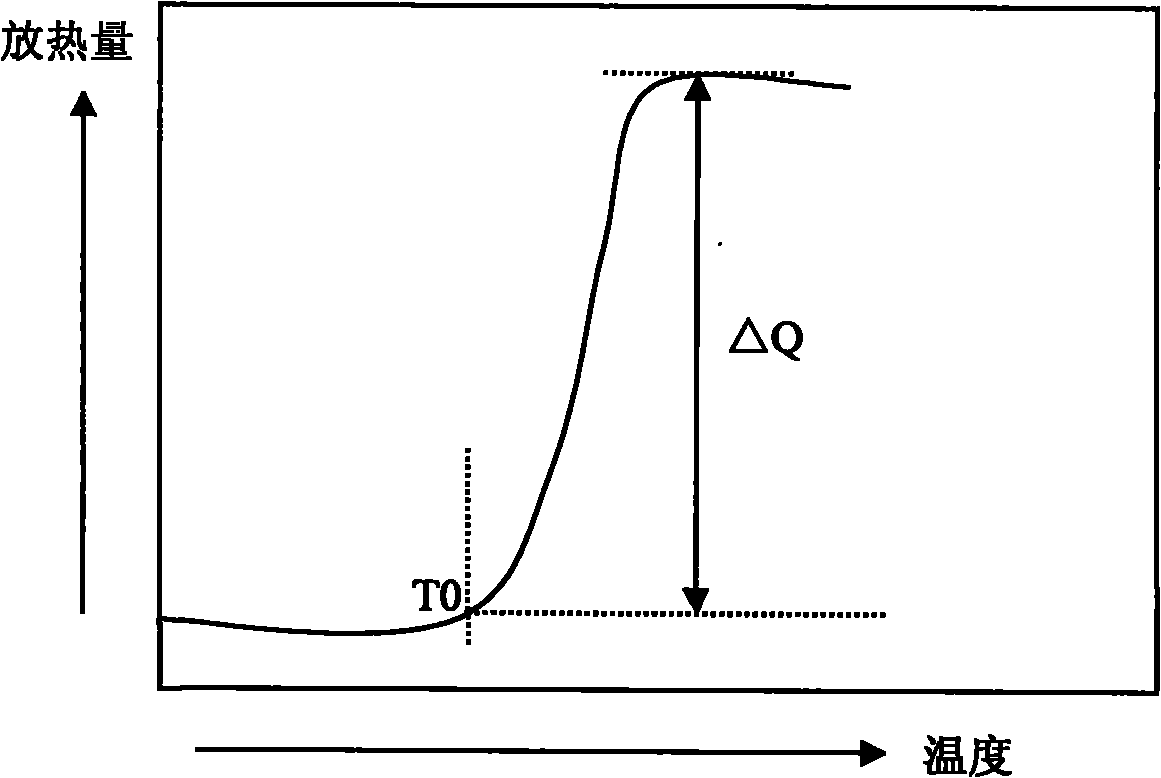

Method used

Image

Examples

Embodiment 1

[0031] The heating agent is weighed by mass percentage from the following raw materials:

[0032] Aluminum powder 20%

[0033] Calcium Silicon Oxide 50%

[0034] Graphite 25%

[0035] Ferric oxide 5%

[0036] Rare earth oxides 0%

[0037] Mix the raw materials uniformly in the mixing equipment to obtain the exothermic agent whose properties are shown in Table 1.

Embodiment 2

[0039] The heating agent is weighed by mass percentage from the following raw materials:

[0040] Aluminum powder 30%

[0041] Calcium Silicon Oxide 40%

[0042] Graphite 25%

[0043] Ferric oxide 5%

[0044] Rare earth oxides 0%

[0045] Mix the raw materials uniformly in the mixing equipment to obtain the exothermic agent whose properties are shown in Table 1.

Embodiment 3

[0047] The heating agent is weighed by mass percentage from the following raw materials:

[0048] Aluminum powder 30%

[0049] Calcium Silicon Oxide 30%

[0050] Graphite 25%

[0051] Ferric oxide 7%

[0052] Rare earth oxides 8%

[0053] Mix the raw materials uniformly in the mixing equipment to obtain the exothermic agent whose properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com