Electric power supply device

A technology for power supply devices and vehicles, which is applied in the directions of electric power devices, vehicle energy storage, power devices, etc., to achieve the effects of compact structure, effective cooling, and compact configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

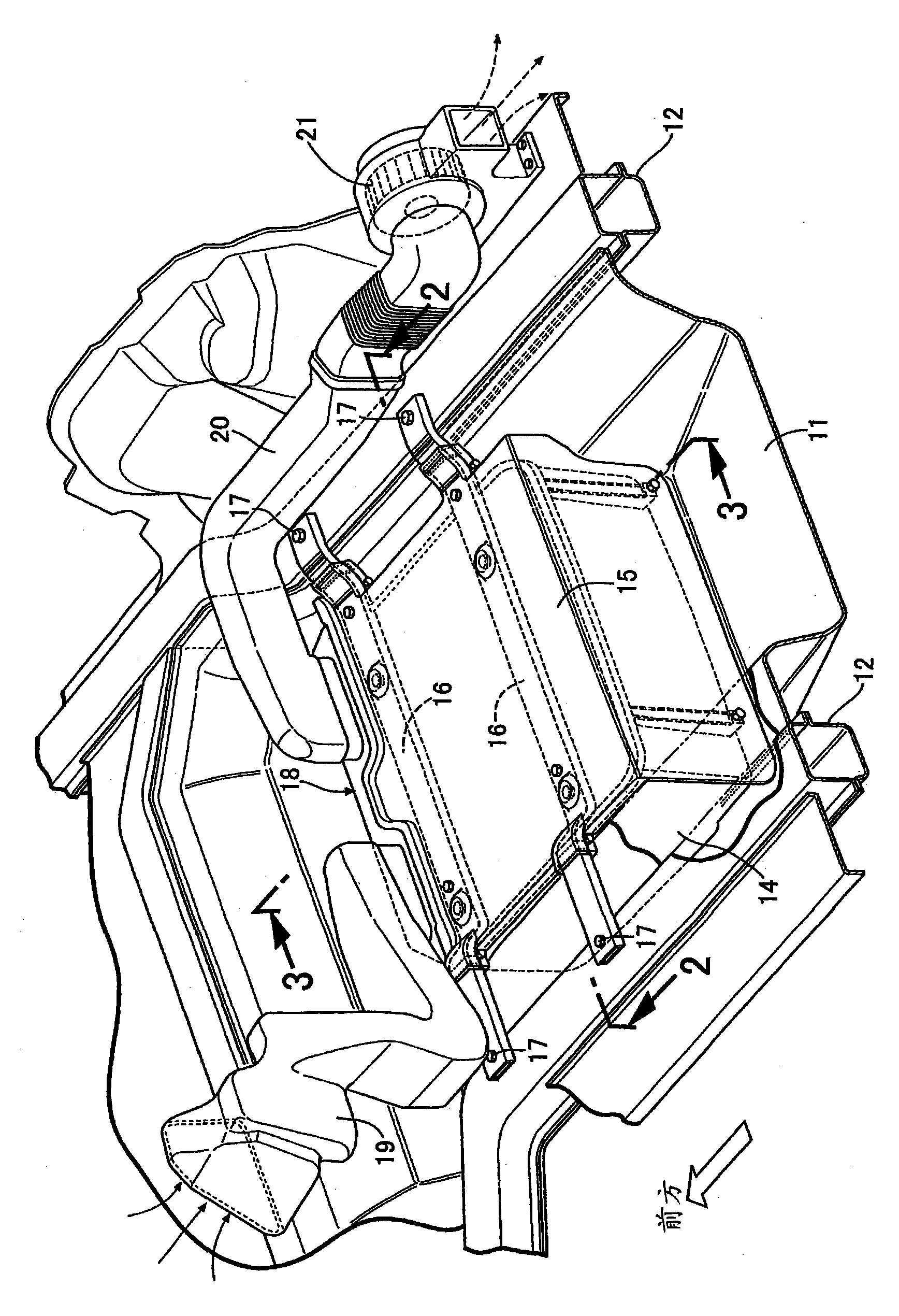

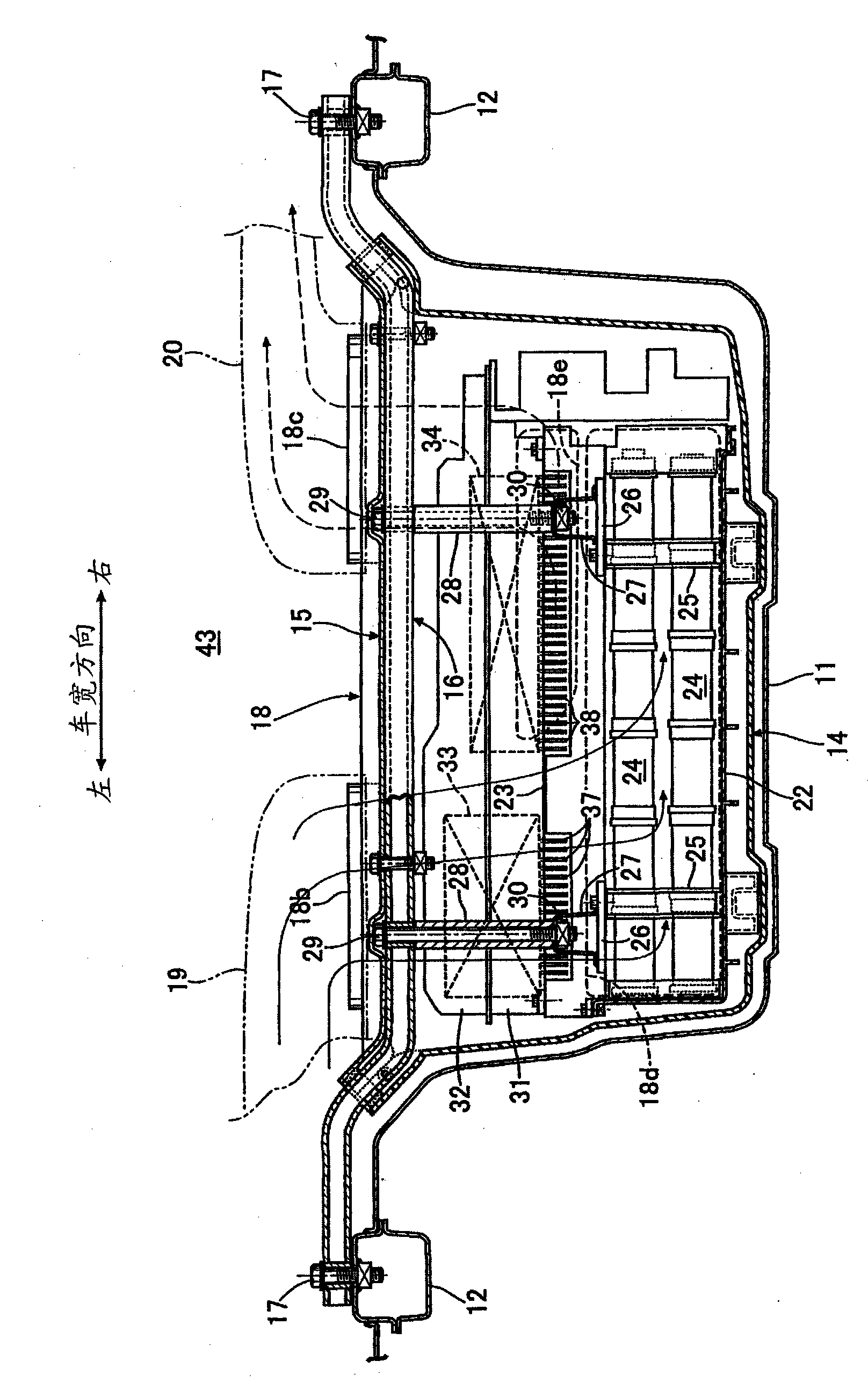

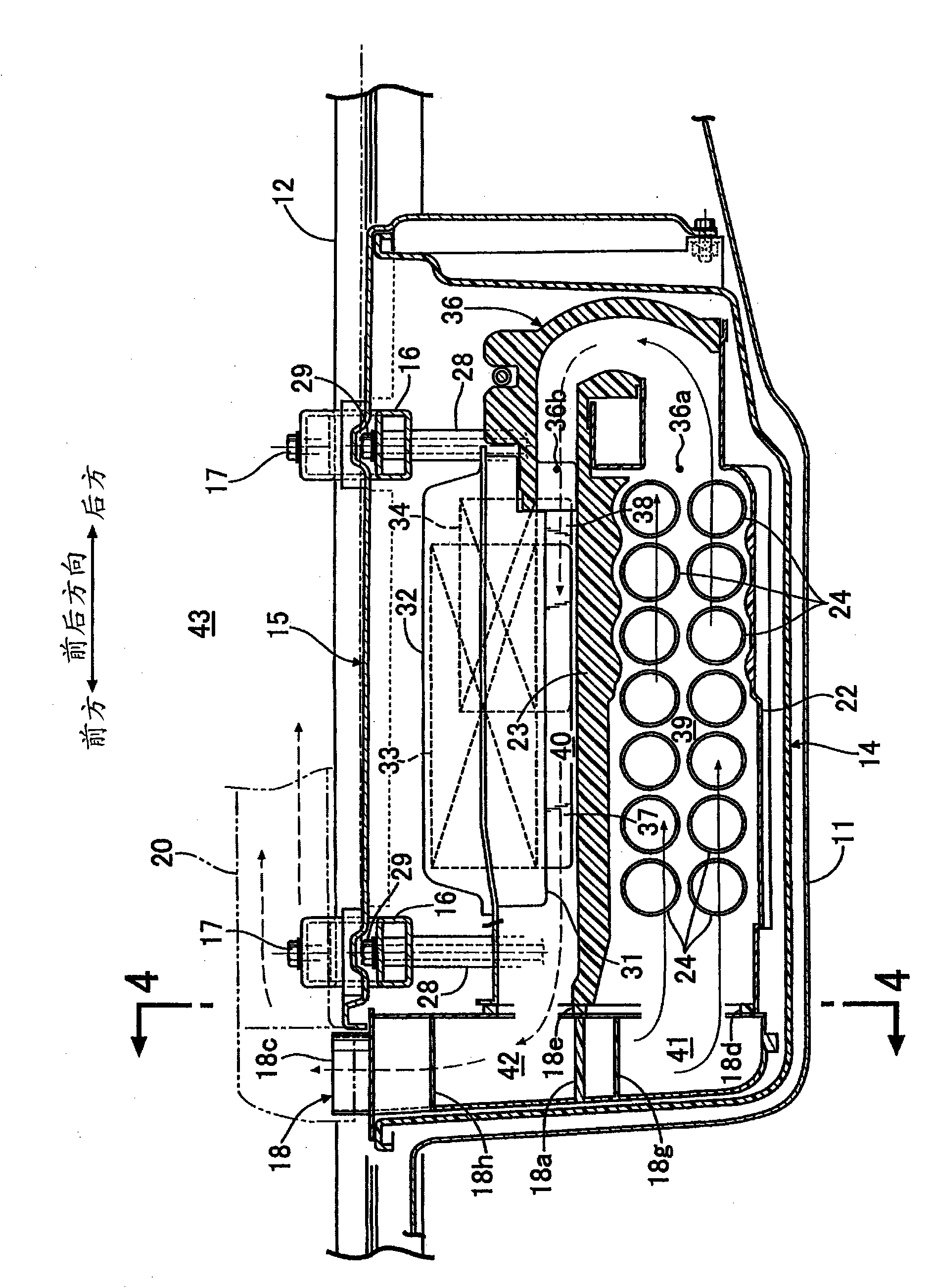

[0036] First, based on Figure 1 to Figure 8 A first embodiment of the present invention will be described.

[0037] Such as figure 1 As shown, a power supply device for operating a motor / generator of a hybrid vehicle is accommodated by using a tire pan 11 in a trunk 43 at the rear of the vehicle body (refer to figure 2 and image 3 ) to accommodate the spare wheel. Left and right side edges of a container-shaped tire disc 11 depressed downward are connected to left and right rear side members 12 , 12 . The power supply unit includes a container-shaped waterproof case 14 with an open upper surface, a flat plate-shaped cover member 15 that closes the upper surface opening of the waterproof case 14, and a pair of front and rear suspension frames 16, 16 at both ends in the vehicle width direction. The pair of suspension frames 16 and 16 are fixed to the upper surfaces of the left and right rear side members 12 and 12 by bolts 17 . Therefore, the power supply unit is suspend...

no. 2 approach

[0061] Next, based on Figure 9 A second embodiment of the present invention will be described.

[0062] The duct member 18 of the second embodiment is configured by combining the intake passage portion 41 and the exhaust passage portion 42 as separate members and integrally combining them. In this embodiment, although the number of components is increased compared with the first embodiment, the degree of freedom in designing the shape of the duct member 18 is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com