Heat-dissipation coating with phase-changing temperature adjusting function and preparing method of heat-dissipation coating

A heat-dissipating coating and temperature-adjusting technology, which is applied in the direction of radiation-absorbing coatings, microsphere preparation, and heat-exchanging materials, can solve the problems of low heat radiation efficiency and poor heat dissipation effect, and achieve excellent performance, good cooling effect, Effect of lowering the internal temperature of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Dissolve a total of 80g of dispersant in 800g of water, add 200g of wall material monomers styrene and divinylbenzene (mass ratio: 2:1) and 200g of paraffin, raise the temperature until the solids in the system are completely dissolved, and adjust Emulsify the system for 3 hours at the rotational speed of the agitator. After the emulsification process, a calculated amount of oil-soluble initiator was added to the mixture to initiate the polymerization reaction of the system, and the phase change microcapsules were obtained after reacting for 10 h under nitrogen purging. Add 8g of phase change microcapsules and 5g of silicon carbide into 100g of epoxy resin, stir for 2 hours, add 40g of room temperature curing agent and mix evenly to prepare a heat dissipation coating with heat storage and temperature adjustment function. After painting, leave it at room temperature for 24 hours, then it will be surface dry, and it will be dry after 72 hours.

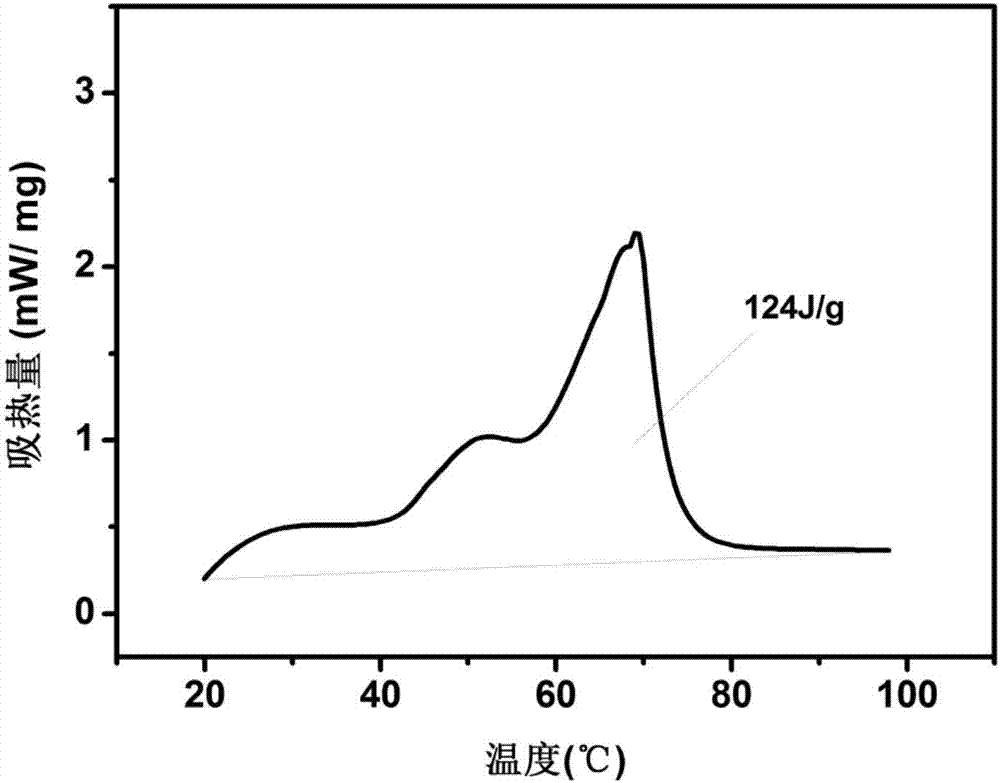

[0042] The differential sc...

Embodiment 2

[0045] Add 150g of wall material monomers styrene and divinylbenzene (mass ratio: 2:1) and 70g of stearic acid and normal long-chain alkanes into the reactor, raise the temperature until the solids in the system are completely dissolved, and then keep warm for later use. After dissolving a total of 10g of dispersant in 1000g of water, pour the mixture obtained in step (a), raise the temperature to 40°C, start the stirrer, adjust the speed to about 100r / min, and emulsify the system for 10 minutes. After the emulsification process, add 1g of oil-soluble initiator to the mixture to initiate the polymerization reaction of the system, adjust the stirrer speed to 150r / min, react for 2h under nitrogen purging, and discharge the material out of the kettle to obtain phase change microcapsules. Add phase-change microcapsules and high-heat radiation materials such as aluminum nitride into epoxy resin, and disperse for 0.5 hours to obtain a heat-dissipating coating with phase-change temper...

Embodiment 3

[0047] Add 300g of wall material monomers styrene and divinylbenzene (mass ratio: 3:1) and 600g of stearic acid into the reaction kettle, raise the temperature until the solids in the system are completely dissolved, and then keep warm for later use. After dissolving a total of 200g of dispersant in 1000g of water, pour the mixture obtained in step (a), raise the temperature to 90°C, start the agitator, adjust the speed to about 2500r / min, and emulsify the system for 80 minutes. After the emulsification process, 15g of oil-soluble initiator was added to the mixture to initiate the polymerization reaction of the system, and the rotation speed of the agitator was adjusted to 1300r / min, and the phase change microcapsules were obtained after reacting for 10h under nitrogen purge. Add phase-change microcapsules and high-heat radiation materials such as beryllium oxide into epoxy resin, and disperse for 4 hours to obtain a heat-dissipating coating with phase-change temperature regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com