Television shell, preparation method thereof and television

A technology for a TV casing and an extruder, applied in the field of TVs and TV casings, can solve the problems of restricting the injection molding of TV casings, inconsistent heat dissipation, warping deformation, etc., so as to solve the problems of poor appearance and warping deformation, and improve the strength and heat resistance, the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] attached Figure 4 It is a flow chart of a method for preparing a TV casing provided in an embodiment of the present application. as attached Figure 4 As shown, the method for preparing a TV casing provided in the embodiment of the present application includes:

[0035] S101: Take raw materials according to the ratio of raw materials.

[0036] According to the ratio of raw materials in the TV casing provided in the above embodiment, the raw materials are taken and mixed evenly. Optionally, put the HIPS and lubricant into a high-speed mixer, stir evenly, then add flame retardant, antioxidant and metal oxide smoke suppressant in sequence, and stir evenly.

[0037] S102: Add uniformly mixed raw materials into the hopper of the extruder, and melt and granulate the raw materials through the extruder to obtain a HIPS composite material.

[0038] After the raw materials are uniformly mixed, the uniformly mixed raw materials are transferred to the hopper of the extruder, a...

Embodiment 1

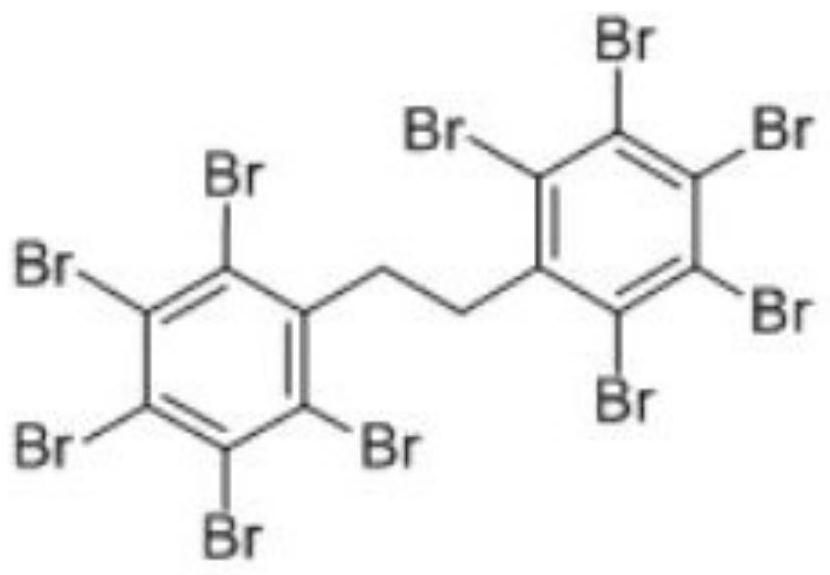

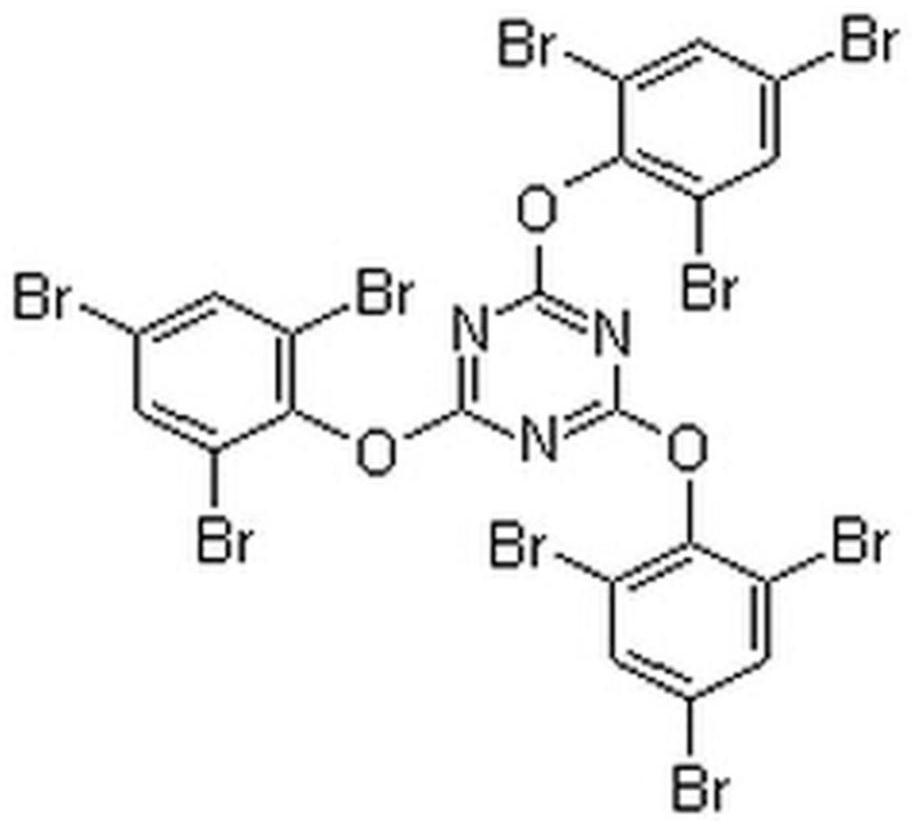

[0046] A kind of TV shell, according to HIPS 85 parts, flame retardant 18.5 parts (decabromodiphenylethane 1.5 parts, brominated triazine 17 parts) and antioxidant 1 part (antioxidant 1010) weight ratio gets raw material, Mix well and evenly; put the uniformly mixed raw materials into the hopper of the extruder, melt and granulate the raw materials through the extruder to obtain HIPS composite materials, and control the front, middle, rear and machine parts of the extruder barrel. The head temperatures were 165° C., 185° C., 195° C. and 210° C.; the HIPS composite material was injection molded to prepare a TV casing. The prepared TV casing has no defects such as hysteresis lines, warping and deformation, and produces little smoke during the manufacturing process.

Embodiment 2

[0048] A TV casing, according to 85 parts of HIPS, 19 parts of flame retardant (1.5 parts of decabromodiphenylethane, 15 parts of brominated triazine, 0.8 part of antimony trioxide), 2.5 parts of antioxidant (antioxidant 1010 ) and 1 part weight ratio of lubricant to get the raw materials, fully mixed uniformly; the uniformly mixed raw materials are added to the hopper of the extruder, and the raw materials are melted and granulated by the extruder to obtain the HIPS composite material, and the extruder is controlled The temperatures of the front, middle, rear and head of the barrel are 168°C, 180°C, 195°C and 220°C respectively; the HIPS composite material is injection molded to prepare a TV casing. The prepared TV casing has no defects such as hysteresis lines, warping and deformation, and produces little smoke during the manufacturing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com