Preparation method of modified ABS material, manufacturing method of cambered rear shell and rear shell

A technology of ABS materials and manufacturing methods, applied in the direction of acrylonitrile butadiene styrene polymer adhesives, adhesive types, adhesive additives, etc., can solve the problem of small TV rear shell size, and overcome product size Smaller, meet product size requirements and assembly requirements, and improve heat resistance and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

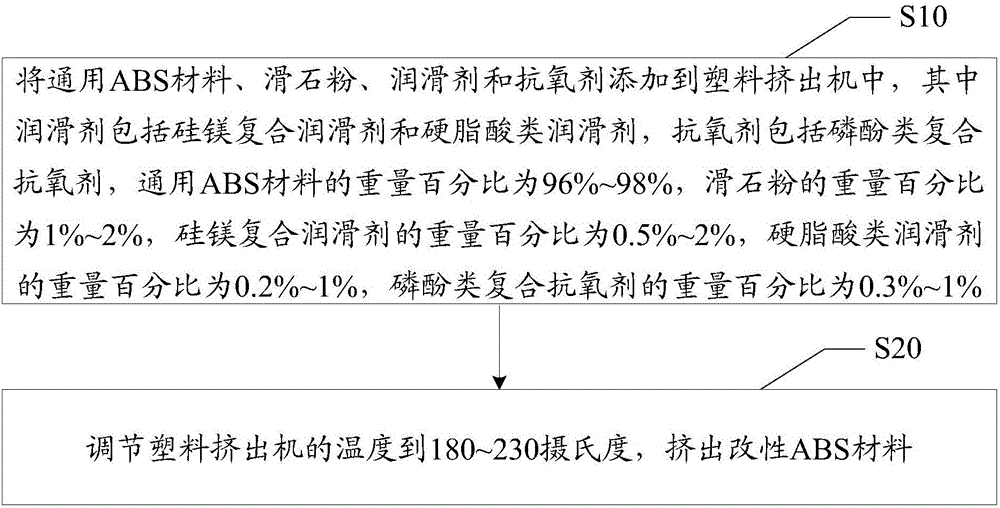

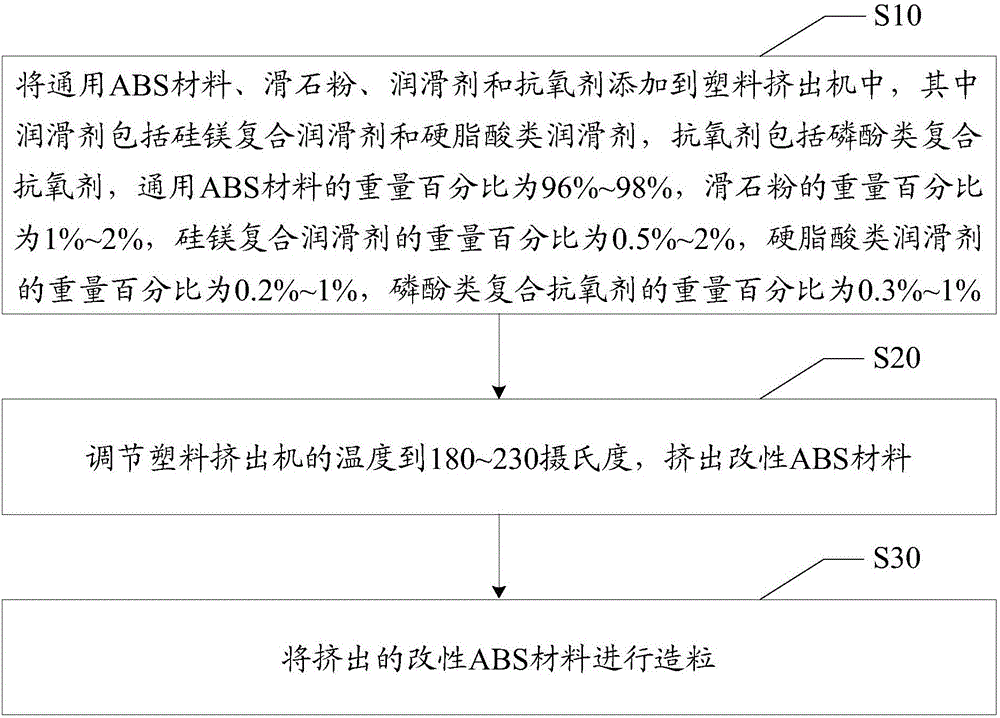

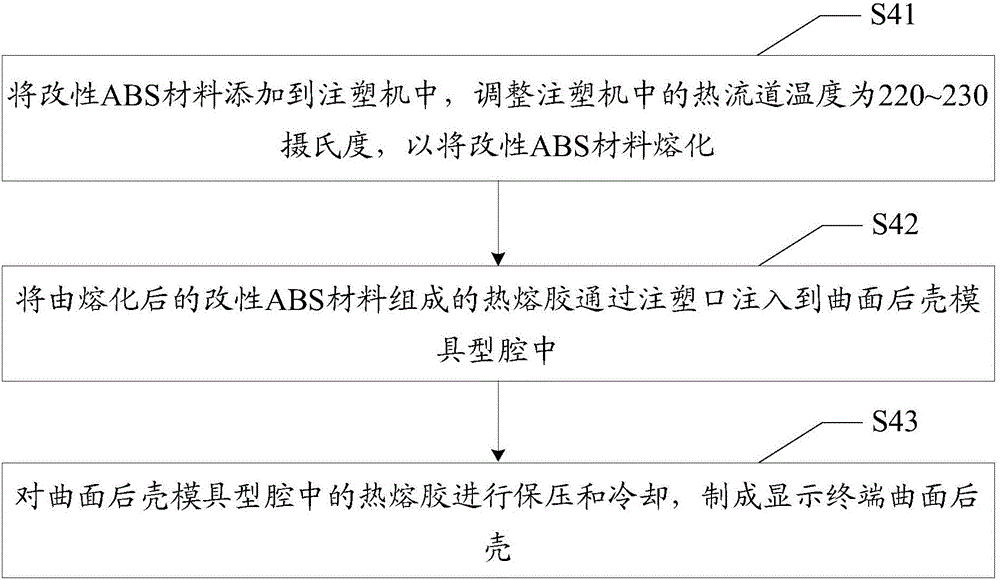

[0028] The present invention provides a kind of manufacturing method of modified ABS material, in one embodiment of the manufacturing method of modified ABS material, refer to figure 1 , the manufacture method of this modified ABS material comprises:

[0029] Step S10, adding general-purpose ABS material, talcum powder, lubricant and antioxidant to the plastic extruder, wherein the lubricant includes silicon-magnesium composite lubricant and stearic acid lubricant, and the antioxidant includes phosphorus phenol compound Antioxidant, the weight percentage of general-purpose ABS material is 96%-98%, the weight percentage of talc powder is 1%-2%, the weight percentage of silicon-magnesium composite lubricant is 0.5%-2%, stearic acid lubricant The weight percentage of the compound antioxidant is 0.2% to 1%, and the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com