Modified halloysite nanotube / biodegradable polyester composite material and preparation method thereof

A halloysite nanotube and biodegradable polyester technology, applied in the field of medical composite materials, can solve the problems of unsatisfactory mechanical properties and insufficient mechanical strength of biodegradable polyester, and achieve easy mass production and good biocompatibility. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

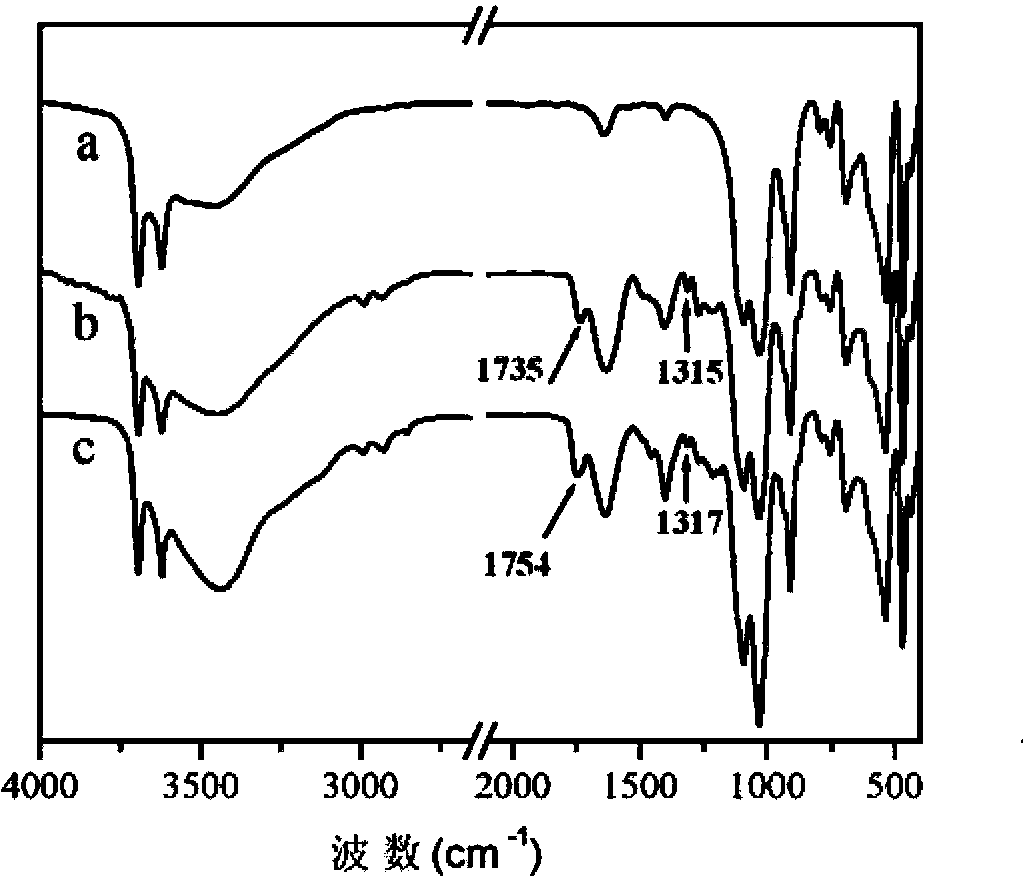

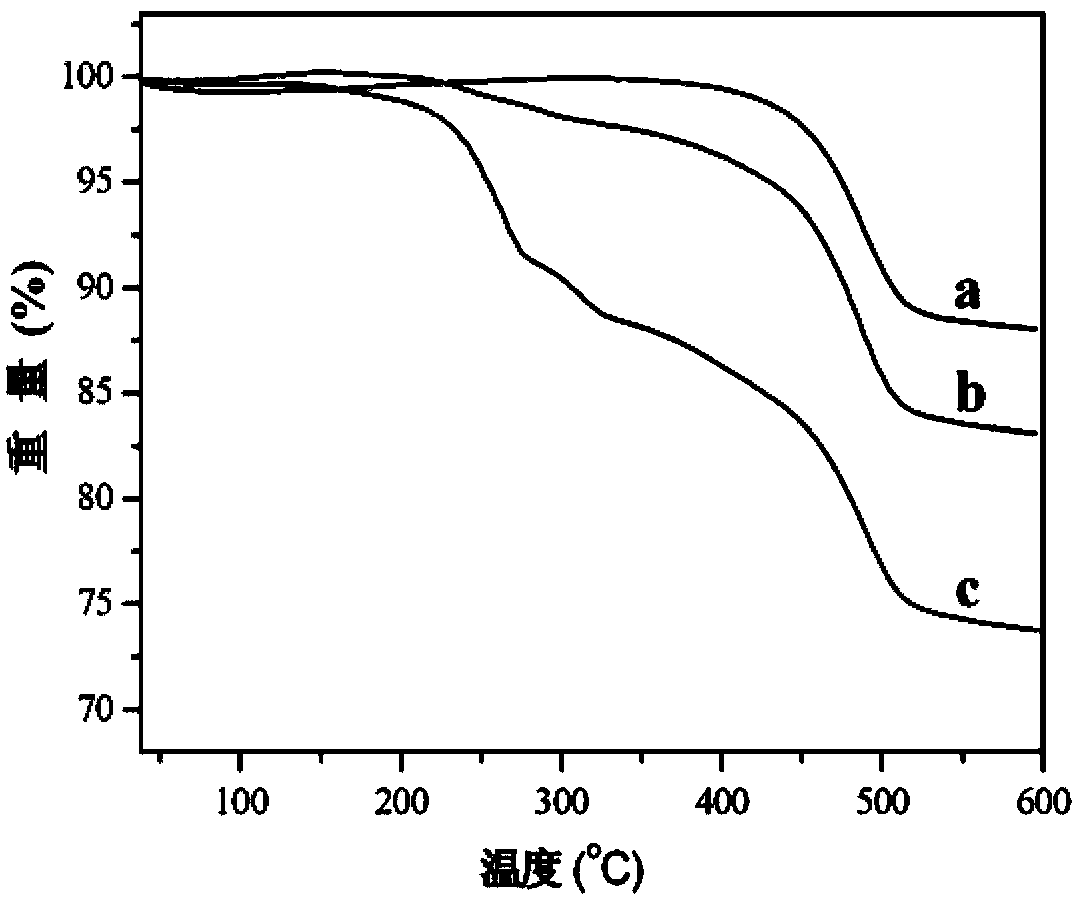

[0037] The preparation of modified halloysite nanotubes comprises the following steps:

[0038]In a three-necked flask, vacuum-dried halloysite nanotubes (30 g) were dispersed in tetrahydrofuran, and D,L-lactic acid (300 mL, 361 g) was slowly added through a dropping funnel under stirring conditions. After the addition was complete, React at 50°C for 6h, then distill off the solvent. Add 400mL of anhydrous toluene, azeotropic dehydration reaction at 110°C for 5h. After the reaction, the product was separated by high-speed centrifugation, and the supernatant was removed to obtain a solid product. The solid product was washed alternately and repeatedly ultrasonically with chloroform and absolute ethanol to remove lactic acid monomers adsorbed on the surface of the solid product. Finally, the solid product was collected by high-speed centrifugation and dried in vacuum to obtain halloysite nanotubes (l-HNTs) grafted with lactic acid on the surface.

[0039] Disperse the vacuum-d...

Embodiment 2

[0042] The preparation of modified halloysite nanotubes comprises the following steps:

[0043] In a three-necked flask, vacuum-dried halloysite nanotubes (50 g) were dispersed in tetrahydrofuran, and L-lactic acid (500 mL, 603 g) was slowly added through a dropping funnel under stirring conditions. The reaction was carried out at °C for 12 h, and then the solvent was distilled off. Add 400 mL of anhydrous toluene, and conduct azeotropic dehydration reaction at 110° C. for 10 h. After the reaction, the product was separated by high-speed centrifugation, and the supernatant was removed to obtain a solid product. The solid product was washed alternately and repeatedly ultrasonically with chloroform and absolute ethanol to remove lactic acid monomers adsorbed on the surface of the solid product. Finally, the solid product was collected by high-speed centrifugation and dried in vacuum to obtain halloysite nanotubes grafted with lactic acid on the surface.

[0044] Disperse the v...

Embodiment 3

[0047] The preparation of modified halloysite nanotube / poly (L-lactic acid) nanocomposite material comprises the following steps:

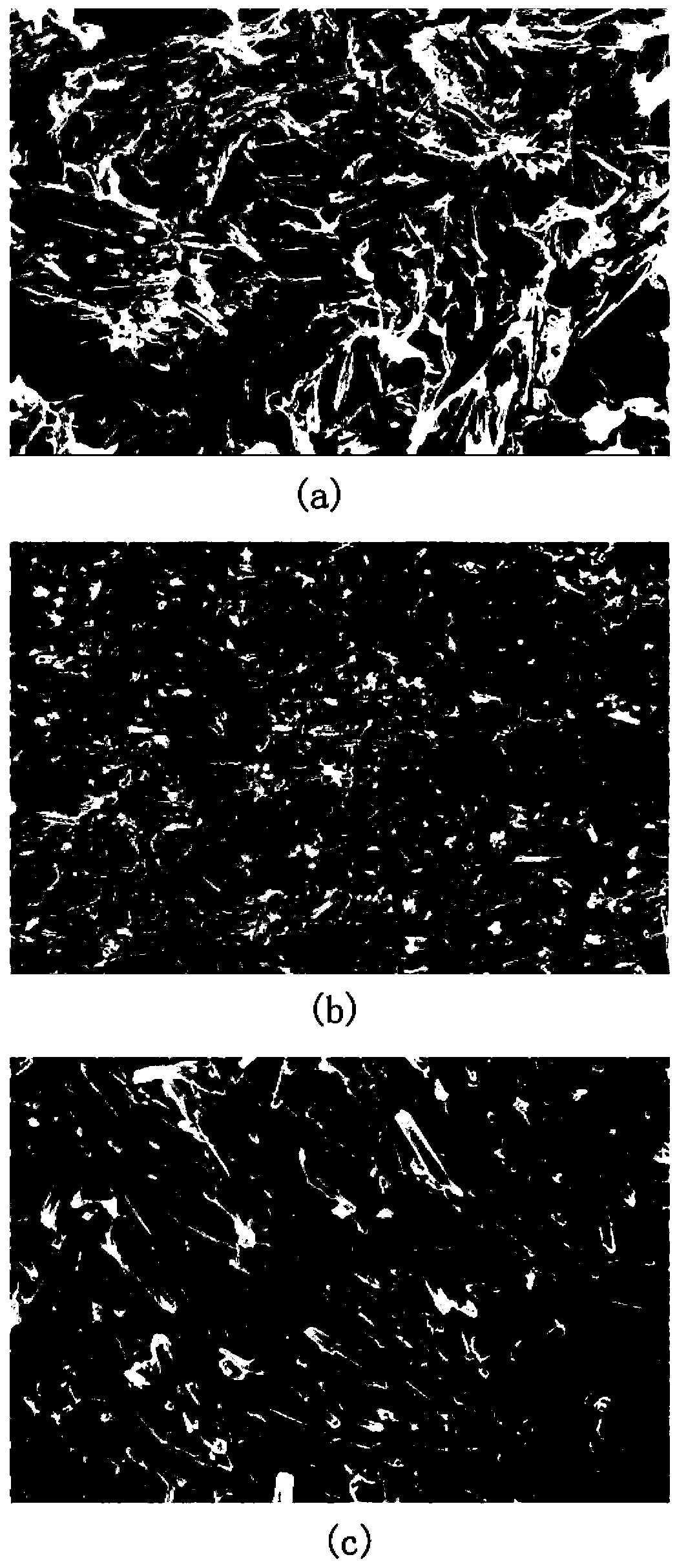

[0048] Mix HNTs, l-HNTs and p-HNTs (l-HNTs and p-HNTs are the products of Example 1) with poly(L-lactic acid) (PLLA) particles with a number average molecular weight of 300,000, and mix them uniformly at 180°C Plate-like HNTs / PLLA, l-HNTs / PLLA and p-HNTs / PLLA nanocomposites were obtained by injection molding with a precision injection machine, wherein the mass ratio of nanotubes in the composites was 2.5-40%. The bending performance of the nanocomposite obtained from the test is shown in the table below, and the cross-sectional morphology of the material is shown in image 3 .

[0049]

[0050] The data in the above table show that the flexural strength and flexural modulus of the l-HNTs / PLLA and p-HNTs / PLLA nanocomposite groups are significantly higher than those of the corresponding HNTs / PLLA nanocomposite group and single PLLA material. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com