A kind of plastic alloy material and preparation method thereof

A plastic alloy and composite material technology, applied in the field of polymer materials, can solve the problems that polymer materials cannot have high strength, high wear resistance and high Vicat softening point at the same time, so as to achieve strong adaptability, reduce wear, and improve The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

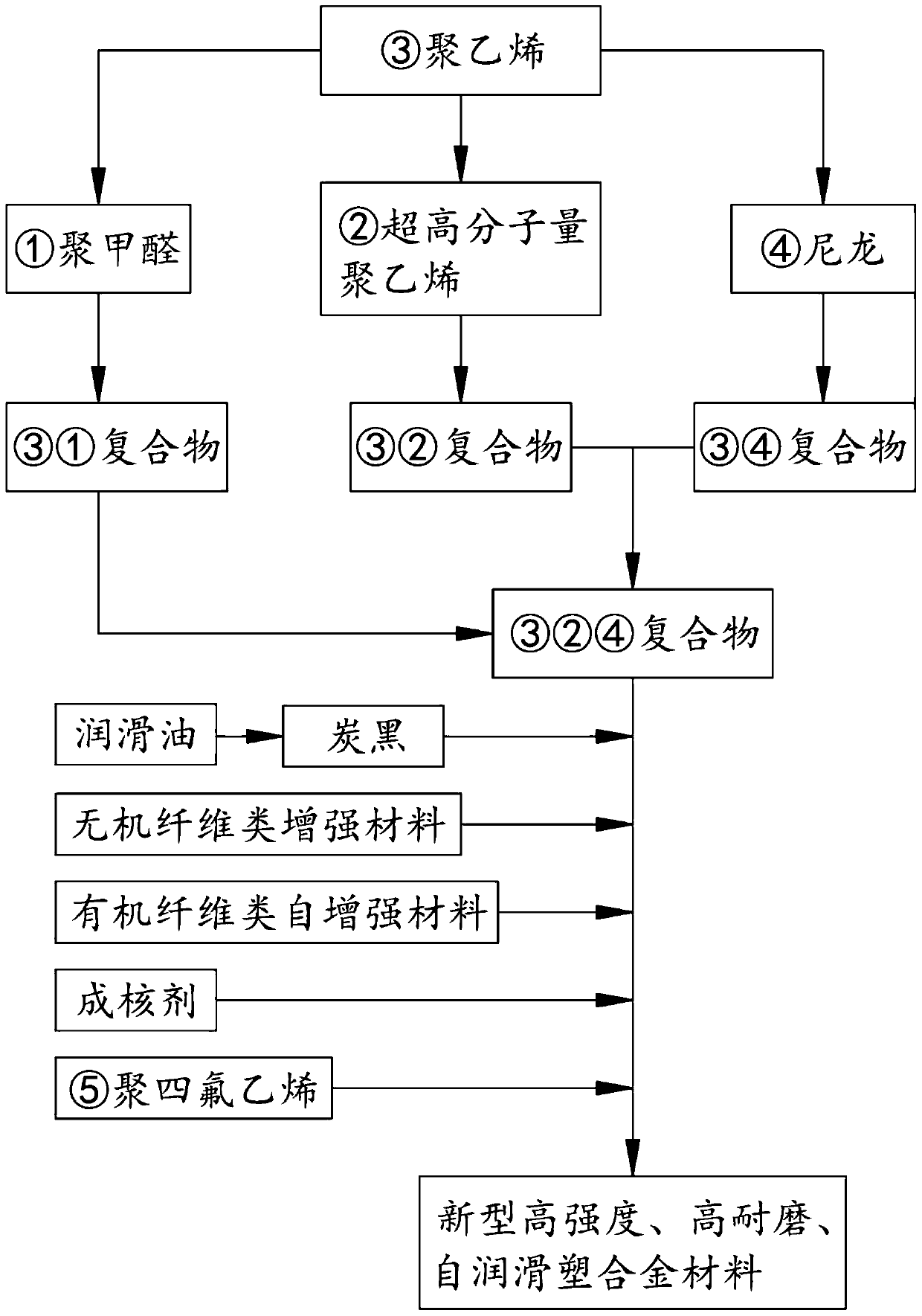

[0032] see figure 1 , is a process flow chart for preparing a novel plastic alloy material of the present invention. The preparation method of a kind of novel plastic alloy material of the present invention comprises the following steps:

[0033] (1) First use graft α to do grafting treatment or surface polarity treatment on material ③;

[0034] (2) Composite the treated material ③ with material ①, material ②, and material ④ respectively to obtain composite materials ③-①, ③-②, ③-④;

[0035] (3) Composite the composite materials ③-② and ③-④ obtained in step (2) to obtain novel composite materials;

[0036] (4) Composite the novel composite material obtained in step (3) with the composite material ③-① obtained in step (2).

[0037] Specifically, during the composite process in step (4), at least one of polymer fibers, carbon fibers, glass fibers, nucleating agents or whiskers should be added for reinforcement treatment. At the same time, 3-10 parts of lubricating oil should ...

Embodiment 1

[0040] A new type of plastic alloy material, composed of various polymer materials and additives. Among them, the main polymer materials and their mass parts are: polyoxymethylene (referred to as material ①): 56 parts, ultra-high molecular weight polyethylene (referred to as material ②): 42 parts, polyethylene (referred to as material ③): 37 parts, nylon (referred to as material ④): 23 parts, polytetrafluoroethylene (referred to as material ⑤): parts.

[0041] A method for preparing a novel plastic alloy material, comprising the following steps:

[0042] (1) First use graft α to do grafting treatment or surface polarity treatment on material ③;

[0043] (2) Composite the treated material ③ with material ①, material ②, and material ④ respectively to obtain composite materials ③-①, ③-②, ③-④;

[0044] (3) Composite the composite materials ③-② and ③-④ obtained in step (2) to obtain novel composite materials;

[0045] (4) Composite the novel composite material obtained in step (...

Embodiment 2

[0048] A new type of plastic alloy material, composed of various polymer materials and additives. Among them, the main polymer materials and their mass parts are: polyoxymethylene (referred to as material ①): 45 parts, ultra-high molecular weight polyethylene (referred to as material ②): 30 parts, polyethylene (referred to as material ③): 27 parts, nylon (referred to as material ④): 32 parts, polytetrafluoroethylene (referred to as material ⑤): 32 parts.

[0049] A method for preparing a novel plastic alloy material, comprising the following steps:

[0050] (1) First use graft α to do grafting treatment or surface polarity treatment on material ③;

[0051] (2) Composite the treated material ③ with material ①, material ②, and material ④ respectively to obtain composite materials ③-①, ③-②, ③-④;

[0052] (3) Composite the composite materials ③-② and ③-④ obtained in step (2) to obtain novel composite materials;

[0053] (4) Composite the novel composite material obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com