Hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material and preparation method thereof

A PA6-POK and alloy material technology, applied in the field of hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material and its preparation, can solve the problems of easy warpage deformation, limited application, high wet volume resistivity, and improve warpage deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

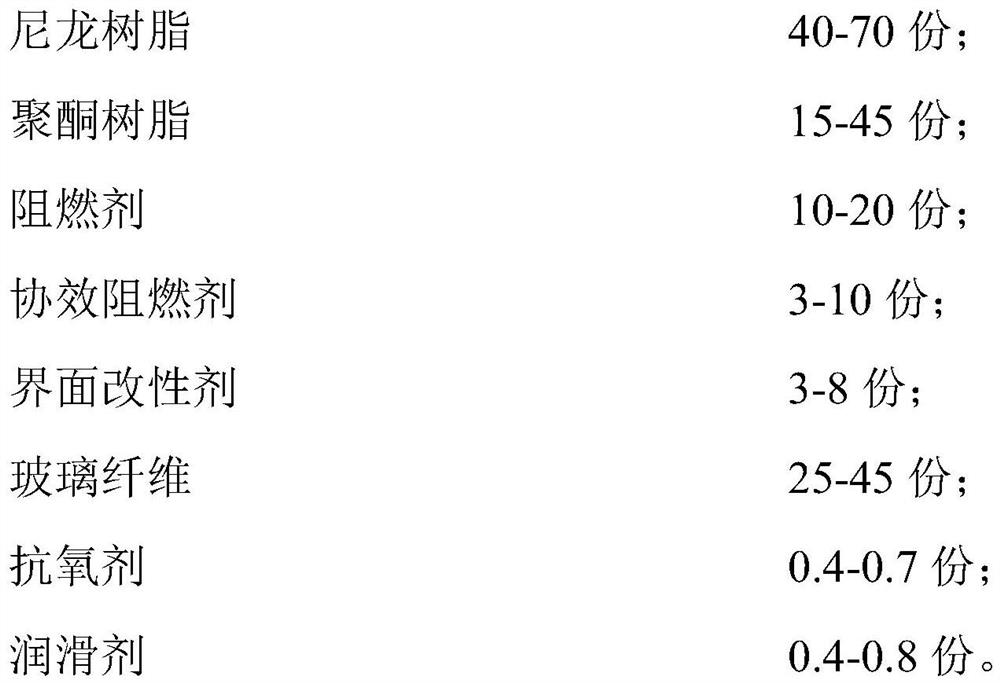

[0034]A hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material, comprising by weight:

[0035]

[0036] Put the above-mentioned materials into the mixer except glass fiber for mixing, put them into the main feeding barrel after mixing, and melt, extrude and granulate through the twin-screw extruder. During the extrusion process, 36 parts of glass fiber pass through the side The feeding method is added, the length-to-diameter ratio of the extruder is 40:1, and the extrusion speed is 300RPM. The temperature of each temperature zone of the extruder is: 220°C in the first zone, 235°C in the second zone, 235°C in the third zone, and 235 in the fourth zone. ℃, five zone 210 ℃, six zone 210 ℃, seven zone 210 ℃, eight zone 210 ℃, head temperature 230 ℃.

Embodiment 2

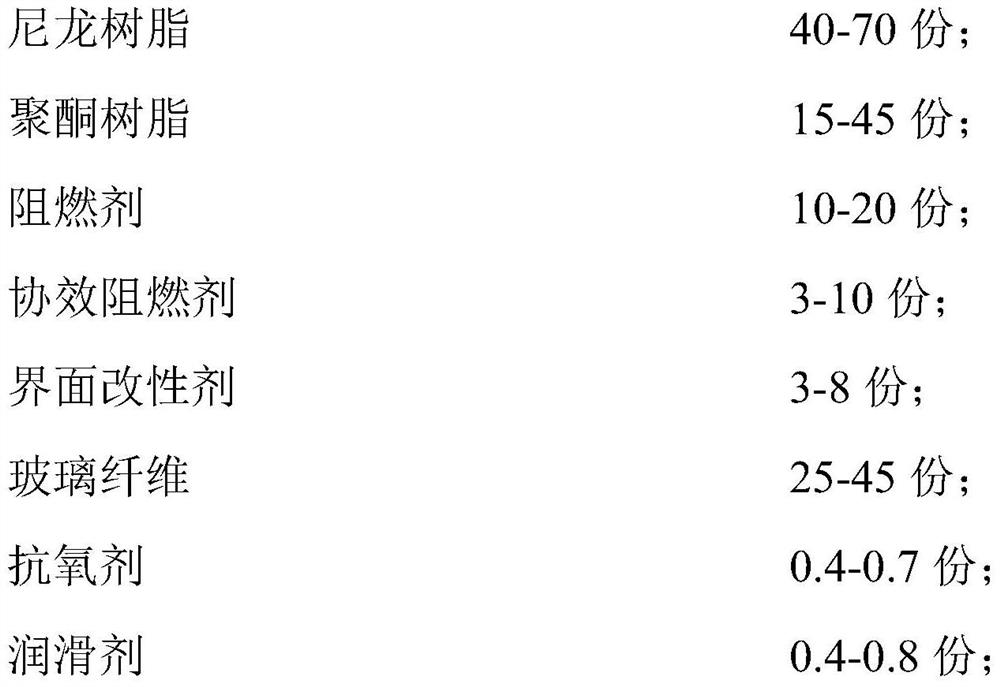

[0038] A hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material, comprising by weight:

[0039]

[0040]

[0041] Put the above-mentioned materials into the mixer except glass fiber for mixing, put them into the main feeding barrel after mixing, and melt, extrude and granulate through the twin-screw extruder. During the extrusion process, 36 parts of glass fiber pass through the side The feeding method is added, the length-to-diameter ratio of the extruder is 40:1, and the extrusion speed is 300RPM. The temperature of each temperature zone of the extruder is: 220°C in the first zone, 235°C in the second zone, 235°C in the third zone, and 235 in the fourth zone. ℃, five zone 210 ℃, six zone 210 ℃, seven zone 210 ℃, eight zone 210 ℃, head temperature 230 ℃.

Embodiment 3

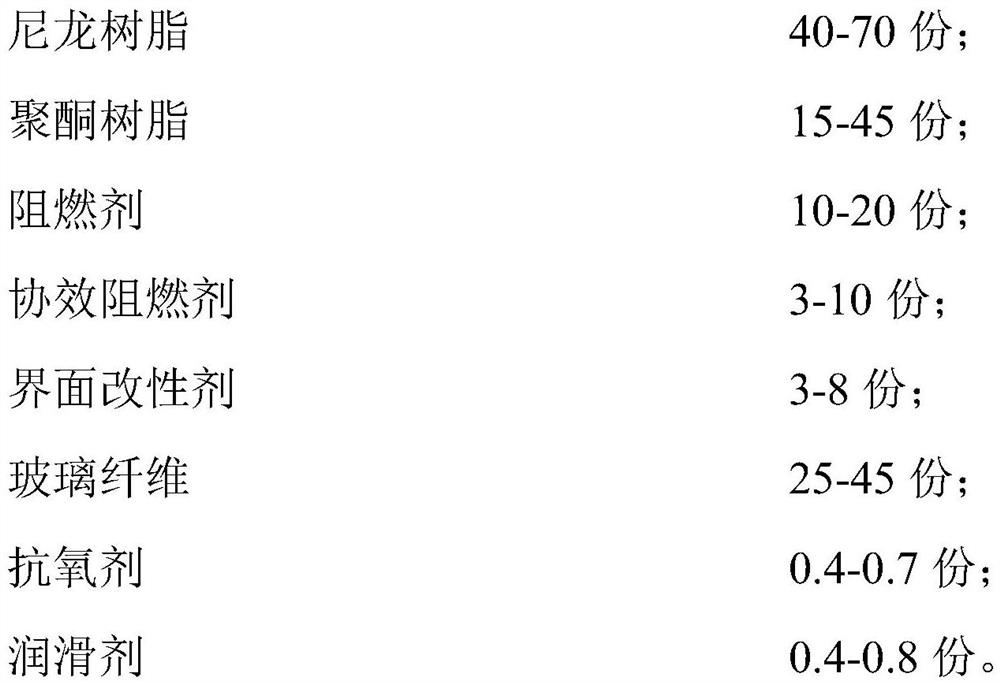

[0043] A hydrolysis-resistant reinforced flame-retardant PA6-POK alloy material, comprising by weight:

[0044]

[0045] Put the above-mentioned materials into the mixer except glass fiber for mixing, put them into the main feeding barrel after mixing, and melt, extrude and granulate through the twin-screw extruder. During the extrusion process, 36 parts of glass fiber pass through the side The feeding method is added, the length-to-diameter ratio of the extruder is 40:1, and the extrusion speed is 300RPM. The temperature of each temperature zone of the extruder is: 220°C in the first zone, 235°C in the second zone, 235°C in the third zone, and 235 in the fourth zone. ℃, five zone 210 ℃, six zone 210 ℃, seven zone 210 ℃, eight zone 210 ℃, head temperature 230 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com