A method for in-situ generation of fiber-reinforced superalloy composites

A fiber-reinforced and composite material technology, applied in the field of in-situ fiber-reinforced superalloy composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

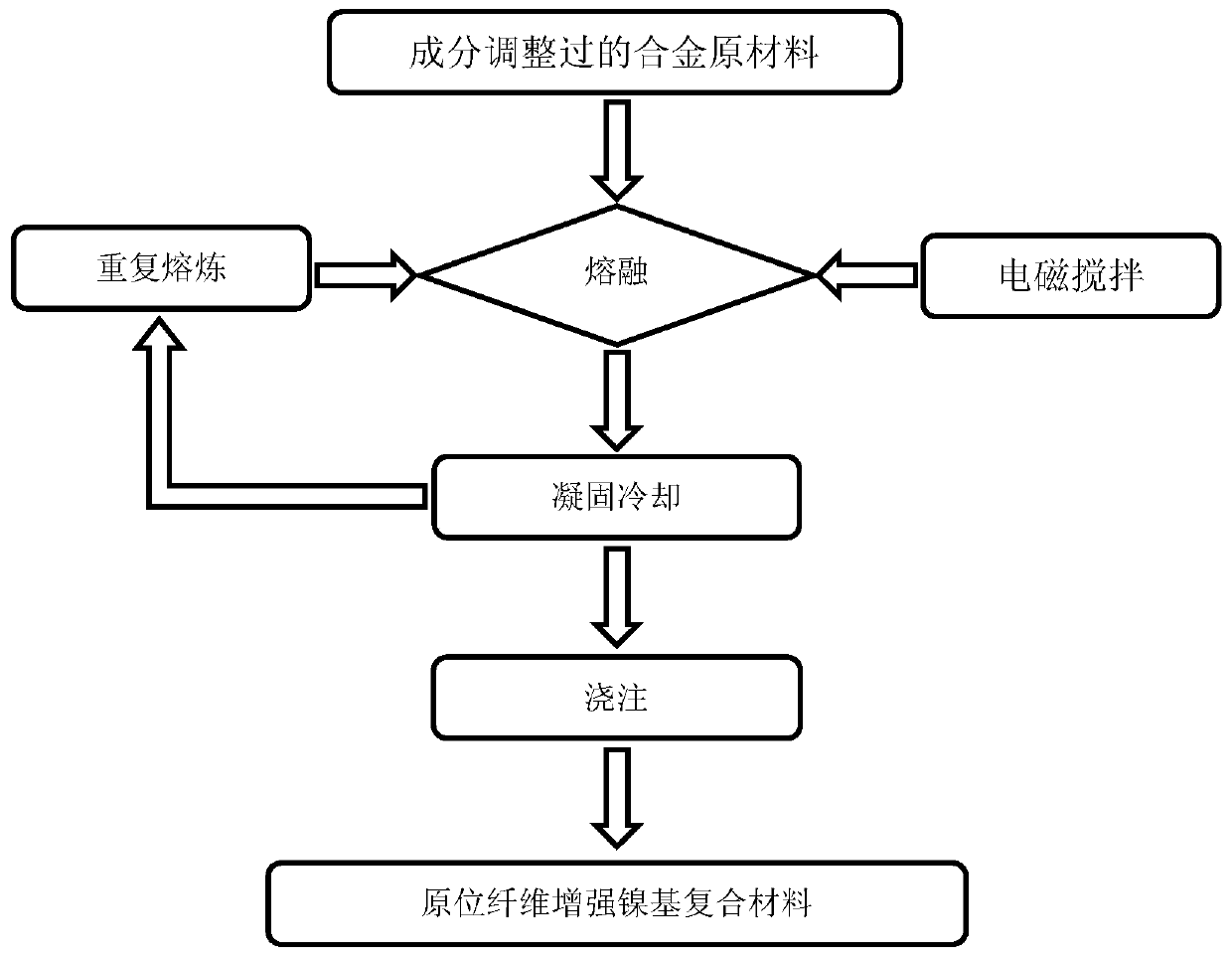

[0026] figure 1 A flowchart showing a method for preparing a fiber-reinforced superalloy-based composite material according to the present invention. Specifically, the following steps are included:

[0027] Step 101, put the composition-adjusted raw material composition of the alloy material into the crucible of the vacuum electric arc furnace according to the proportion. The raw material composition and proportion of the alloy material in step 101 are: chromium element, accounting for 25-40 at.% of the total number of atoms; carbon element, accounting for 15-30 at.% of the total number of atoms; 5at.%, nickel element content is the balance. Wherein, the purity of the nickel, chromium, carbon and titanium is not lower than 98%. Experiments have proved that when the carbon element accounts for 15-30 at.% of the total atomic number, the interface of the superalloy-based composite material formed is the most stable.

[0028] Step 102, melt the raw material components to a liq...

Embodiment 1

[0032] (1) 22g alloy material raw material (composition is 30at.% chromium, 15at.% carbon, 5at.% titanium, the balance is nickel, wherein, the purity of described nickel, chromium, carbon, titanium is 99%) is put into Vacuum non-consumable electric arc furnace crucible.

[0033] (2) Under the protection condition of argon gas with a pressure of 0.02MPa, the raw material components were smelted to a liquid state by vacuum arc melting, and the melt was stirred by an electromagnetic stirring device at the same time. The electromagnetic stirring current value was 1A, and the stirring time was 6 minutes.

[0034] (3) After the melt was solidified and cooled, the melting was repeated six times, and poured into a metal mold to obtain an in-situ fiber-reinforced nickel-based composite material.

Embodiment 2

[0036] (1) 22g alloy material raw material (composition is 30at.% chromium, 30at.% carbon, 5at.% titanium, the balance is nickel, wherein, the purity of described nickel, chromium, carbon, titanium is 99%) is put into Vacuum non-consumable electric arc furnace crucible.

[0037] (2) Under the protection condition of argon gas with a pressure of 0.02MPa, the raw material components were smelted to a liquid state by vacuum arc melting, and the melt was stirred by an electromagnetic stirring device at the same time. The electromagnetic stirring current value was 1A, and the stirring time was 6 minutes.

[0038] (3) After the melt was solidified and cooled, the melting was repeated six times, and poured into a metal mold to obtain an in-situ fiber-reinforced nickel-based composite material.

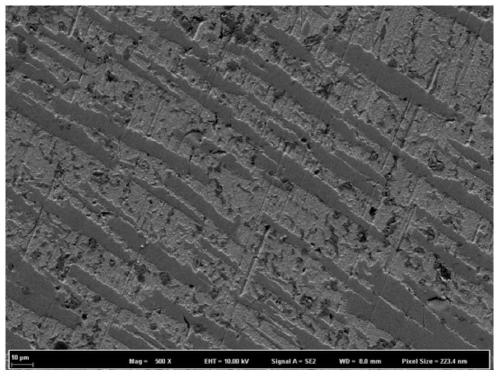

[0039] In the composites prepared in this way, there are a large amount of M 7 C 3 (M is mainly Cr) crystal fiber. m 7 C 3 The phase is a complex hexagonal structure, which can form long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com