FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

A technology of composite materials and composite coatings, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effect of improving the protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of FG@ZIF-8 modified epoxy resin composite coating includes the following steps:

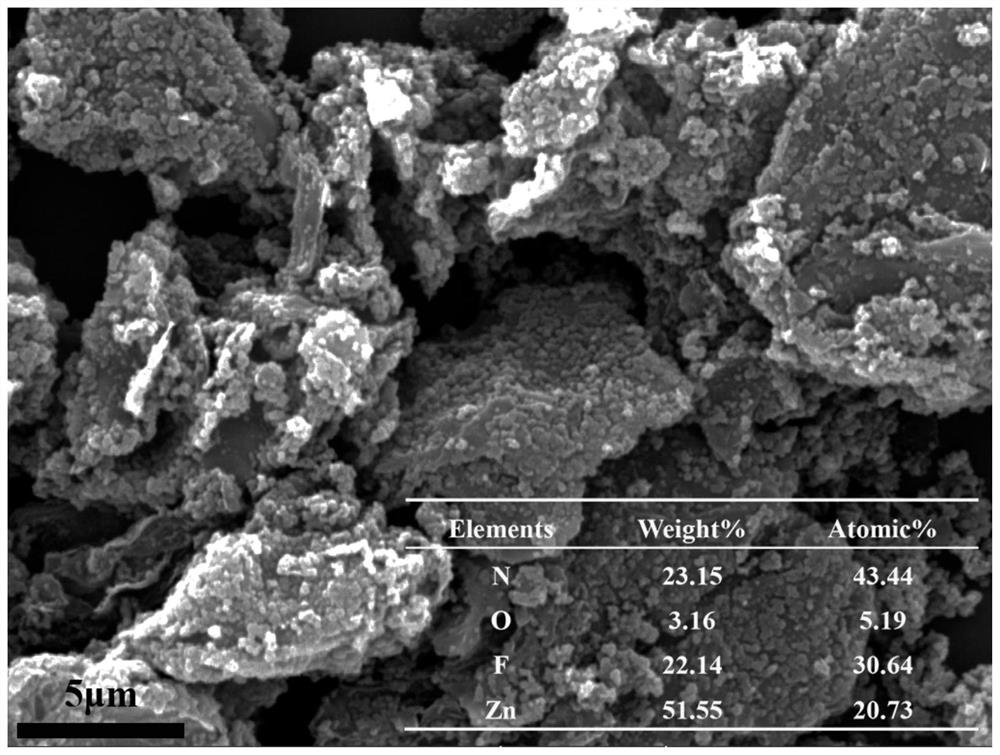

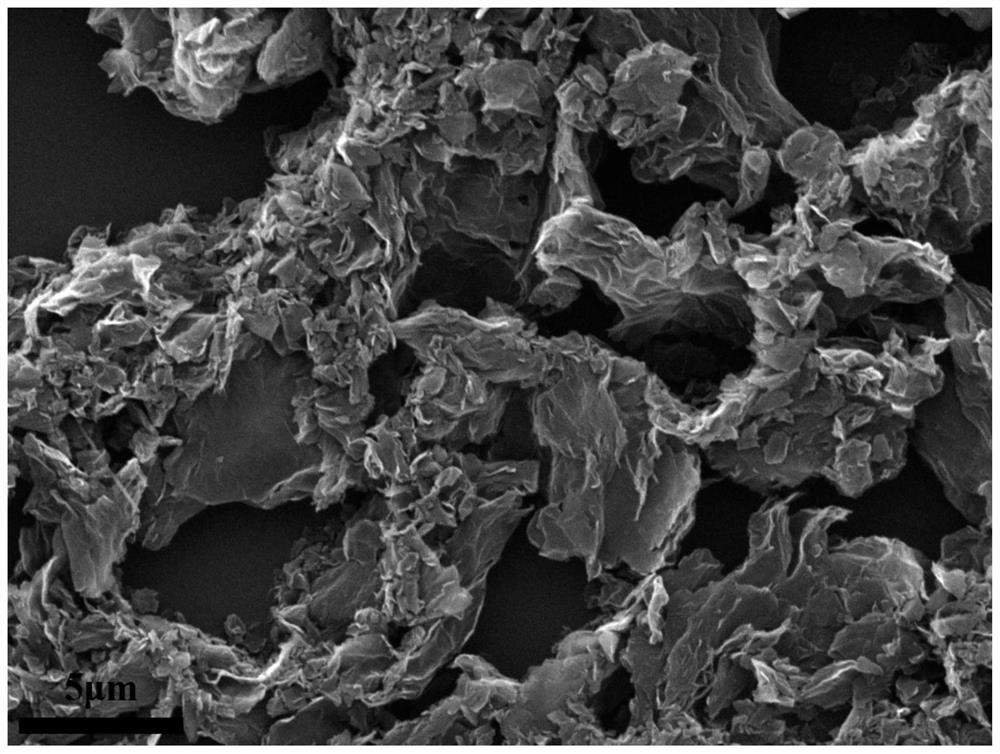

[0028] (1) Preparation of FG@ZIF-8 composite material: Disperse 0.117g of FG in anhydrous methanol, oscillate ultrasonically for 2-3 hours, and then add 0.5g of Zn(NO 3 ) 2 ·6H 2 O and 0.55g of 2-methylimidazole were added to the FG methanol dispersion, stirred for 2 hours to obtain a suspension, which was separated by centrifugation and washed alternately with methanol and deionized water for 4 times, and finally dried at 60°C for 12 hours to obtain a powder In this example, the molar ratio of zinc ions to 2-methylimidazole is 1:4, and the mass fraction of FG in all the raw materials participating in the reaction is 10%.

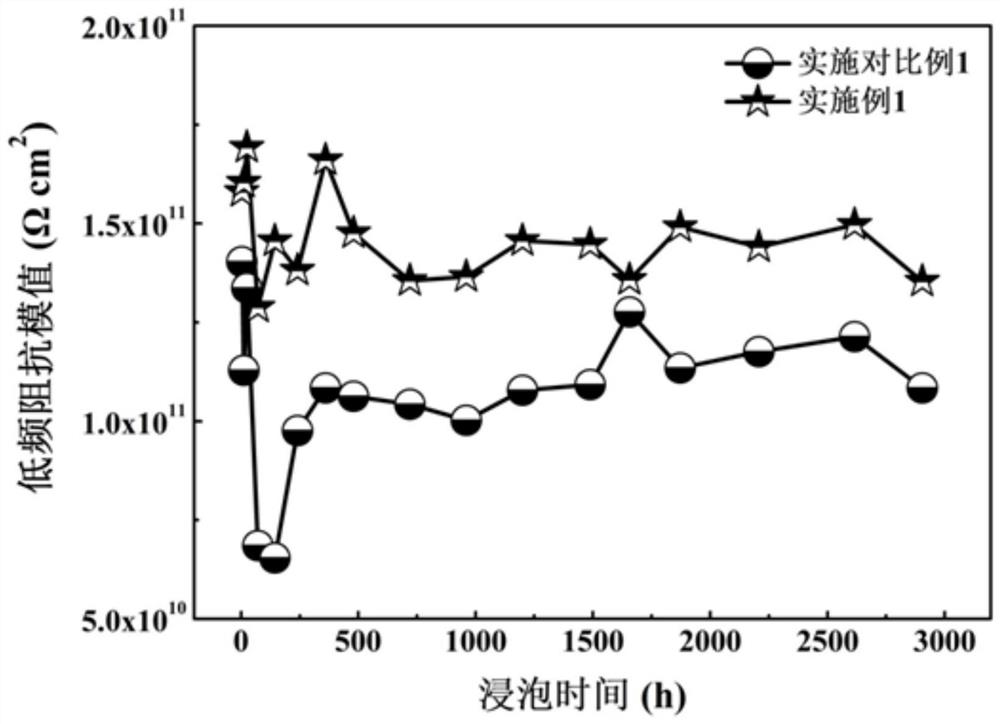

[0029] (2) Preparation of composite coating: mix epoxy resin, FG@ZIF-8 and diluent with a mass ratio of 10:0.5:8, wherein the diluent is a mixture of xylene and n-butanol, and xylene and n-butanol The mass ratio is 2:1; the ball mill is stirred for 0.5h,...

Embodiment 2

[0040] Preparation of FG@ZIF-7 modified epoxy resin composite coating includes the following steps:

[0041] (1) Preparation of FG@ZIF-7 composite material: Disperse 0.233g FG in anhydrous methanol, ultrasonically shake for 2-3h, and then add 0.5g ZnCl 2 and 0.433g of benzimidazole were added to the FG methanol dispersion, stirred for 2 hours to obtain a suspension, which was separated by centrifugation and washed alternately with methanol and deionized water for 4 times, and finally dried at 60°C for 12 hours to obtain powdered FG @MOF composite material, in this example, the molar ratio of zinc ions to benzoimidazole is 1:1, and the mass fraction of FG in all the raw materials participating in the reaction is 20%;

[0042] (2) Preparation of composite coating: mix epoxy resin, FG@ZIF-7 and diluent with a mass ratio of 10:2:10, wherein the diluent is a mixture of xylene and n-butanol, and xylene and n-butanol The mass ratio is 3:1; the ball mill is stirred for 0.5h, and then...

Embodiment 3

[0046] The preparation of aminated FG@ZIF-8 modified epoxy resin composite coating includes the following steps:

[0047] (1) Preparation of aminated FG@ZIF-8 composite material: Disperse 0.8g FG in anhydrous methanol, oscillate ultrasonically for 2-3h, then add 0.5g Zn(NO 3 ) 2 ·6H 2 O, 0.3g 2-methylimidazole and 0.4g 2-aminobenzimidazole were added to the FG methanol dispersion, stirred for 2h to obtain a suspension, which was centrifuged and washed 4 times alternately with methanol and deionized water, and finally in Dry at 60°C for 12 hours to obtain a powdered aminated FG@ZIF-8 composite material. In this example, the molar ratio of zinc ions to imidazole ligands is 1:4, and the mass fraction of FG in all the raw materials participating in the reaction is 40. %;

[0048] (2) Preparation of composite coating: mix epoxy resin, aminated FG@ZIF-8 and diluent with a mass ratio of 10:0.3:2, wherein the diluent is a mixture of xylene and n-butanol, and xylene and n-butanol T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com