Closed gun tower for lightning protection vehicle

A closed, gun turret technology, applied in the field of gun turrets, can solve the problems of being exposed to the enemy, having a large protective plate, and being hit by the shooter, so as to achieve the effects of ensuring life safety, improving protection performance, and improving combat effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

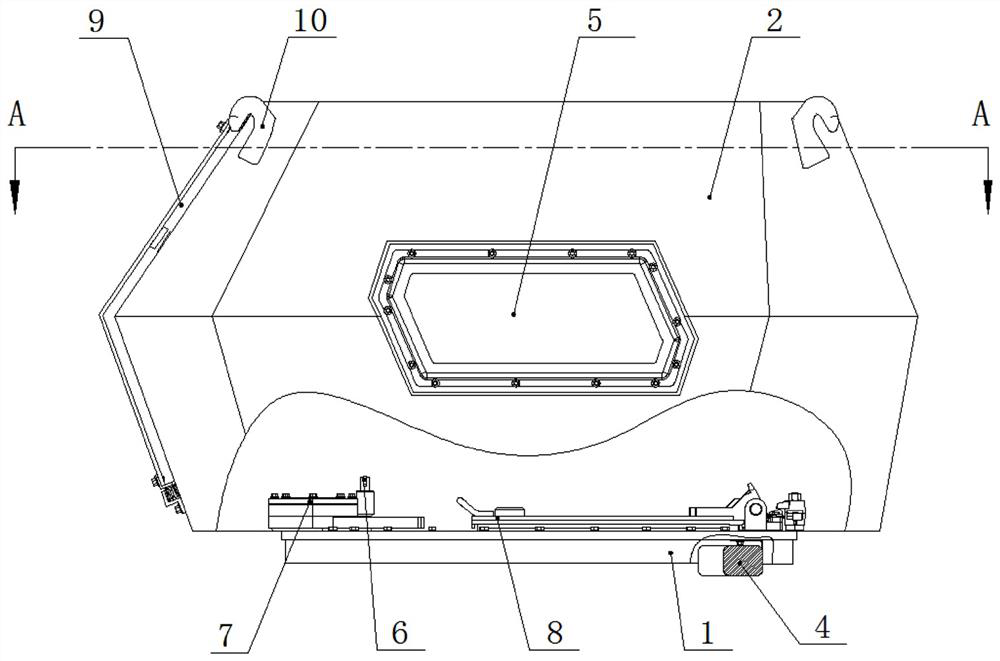

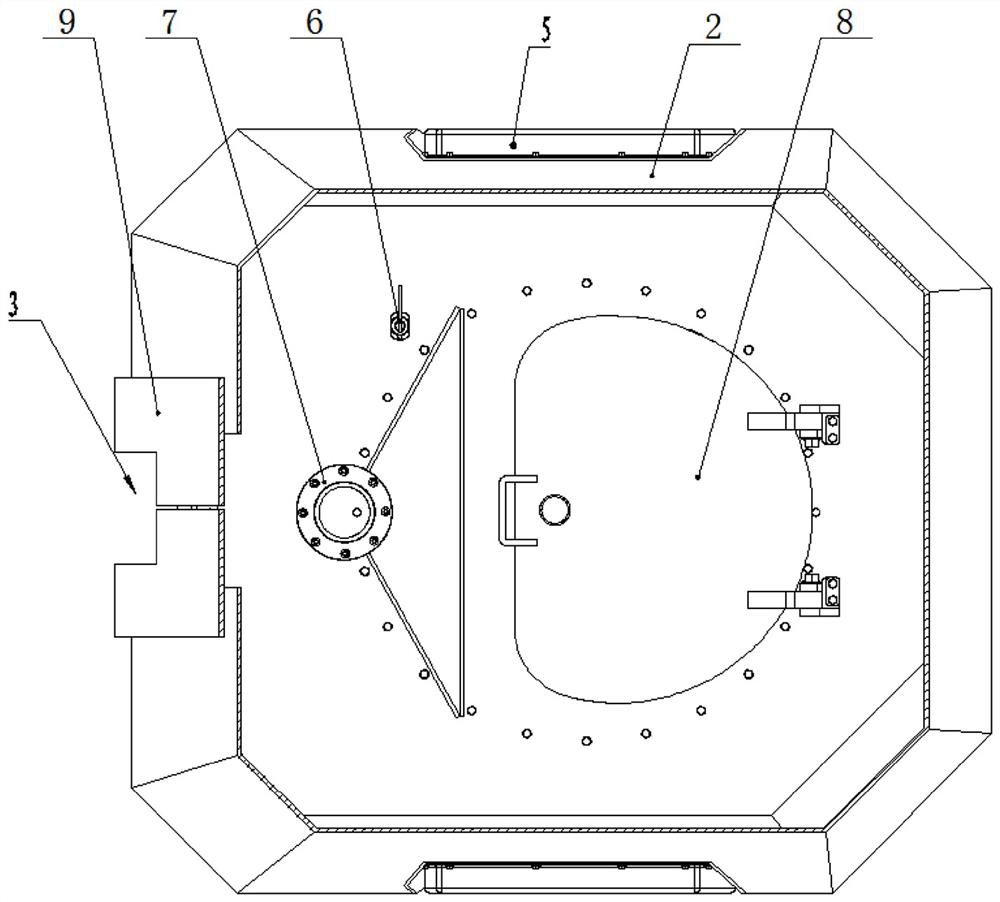

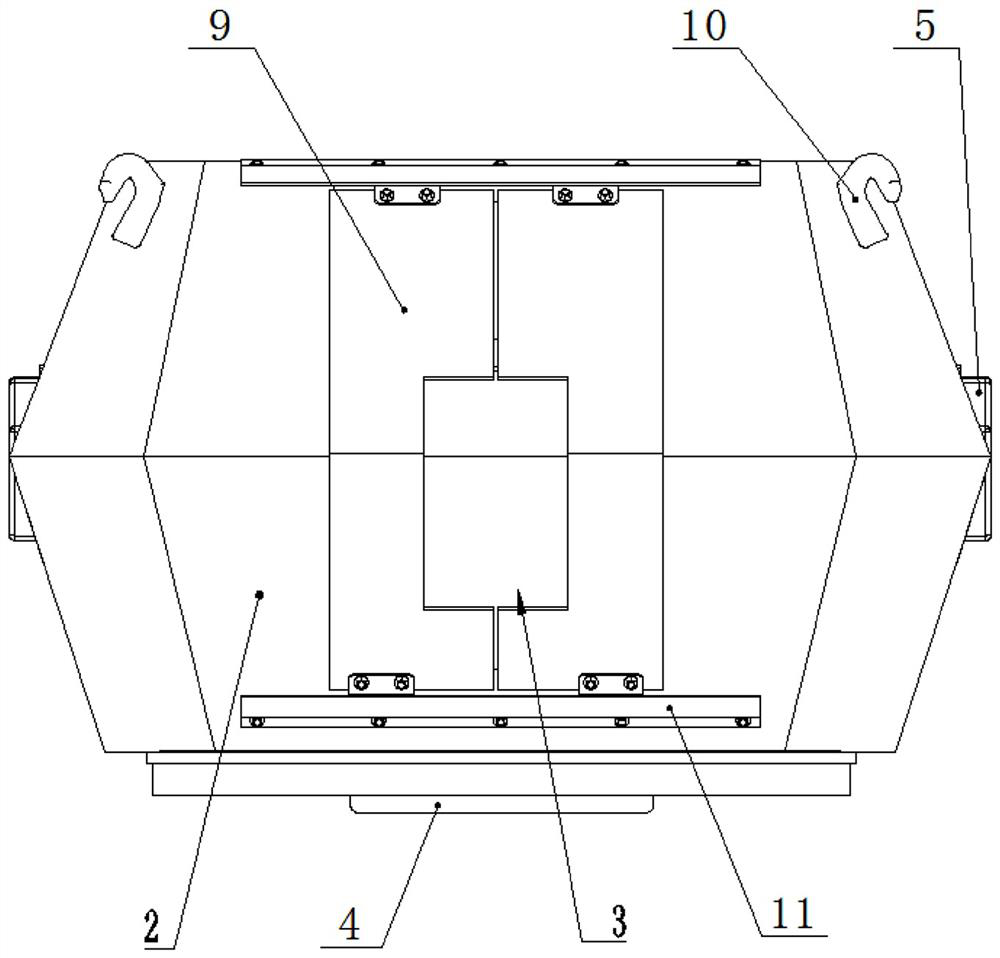

[0021] see Figure 1 to Figure 4 , an embodiment of a closed gun tower used for a lightning protection vehicle, comprising a protective cover 2 with a closed upper end, the protective cover 2 is formed by the bulletproof steel plates arranged around to form a cavity, and the bulletproof steel plates at the top and around are welded Fixed, wherein, the protective cover 2 is surrounded by a number of bulletproof steel plates that are oppositely arranged up and down, and an inclined angle is formed between the two opposite bulletproof steel plates, so that the bulletproof steel plates around the protective cover 2 are inclined to reduce the impact of bullets and improve protective performance. Observation windows 5 are provided on the bulletproof steel plates on both sides of the protective cover 2 . The observation windows 5 in this embodiment are made of transparent armor material and are fixedly connected to the protective cover 2 by bolts. The front end of the protective cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com