Inner ventilated motor

A technology of electric motor and internal air, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., to achieve the effect of short heat flow path, reduced external size and weight, and high protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

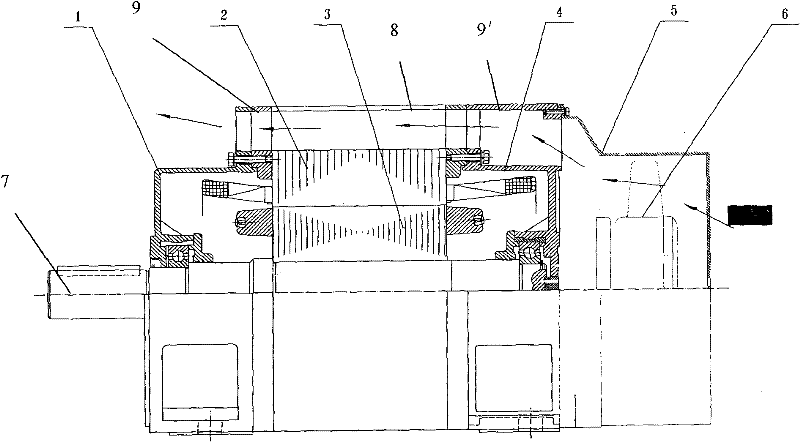

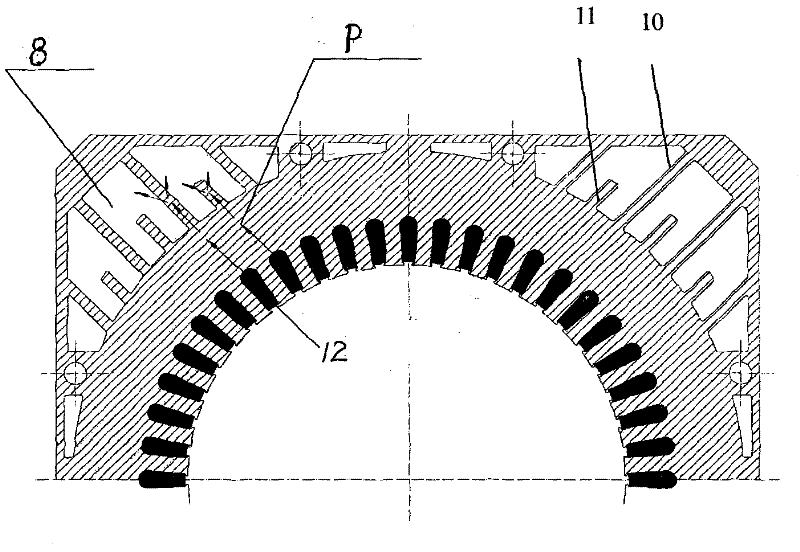

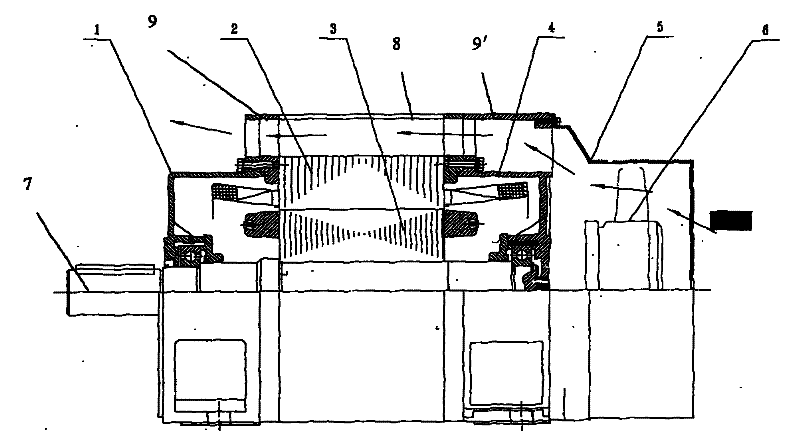

[0011] Such as figure 1 As shown, the present invention includes a motor central shaft 7, a motor rotor 3 sleeved on the central shaft, a stator 2, a left end cover 3 and a right end cover 4 packaged at both ends of the rotor and the stator. In the present embodiment, fan 6 is arranged on the outer end of the right end cover, and is covered with wind cover 5 . On the yoke of the stator core, there is a through stator air guide hole 8 in the axial direction, and correspondingly, on the left end cover 3 and the right end cover 4, there is a through end cover air guide hole that is connected with the stator air guide hole in the axial direction. 9, 9', end cover air guide holes 9, 9' are annular air guide holes. Such as figure 2 As shown, the stator air guide hole 8 surrounds the stator core and is opened on the yoke of the same width as the stator iron core. In the stator air guide hole 8, a radial partition 10 penetrating the axial direction is arranged. Between the radial p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com