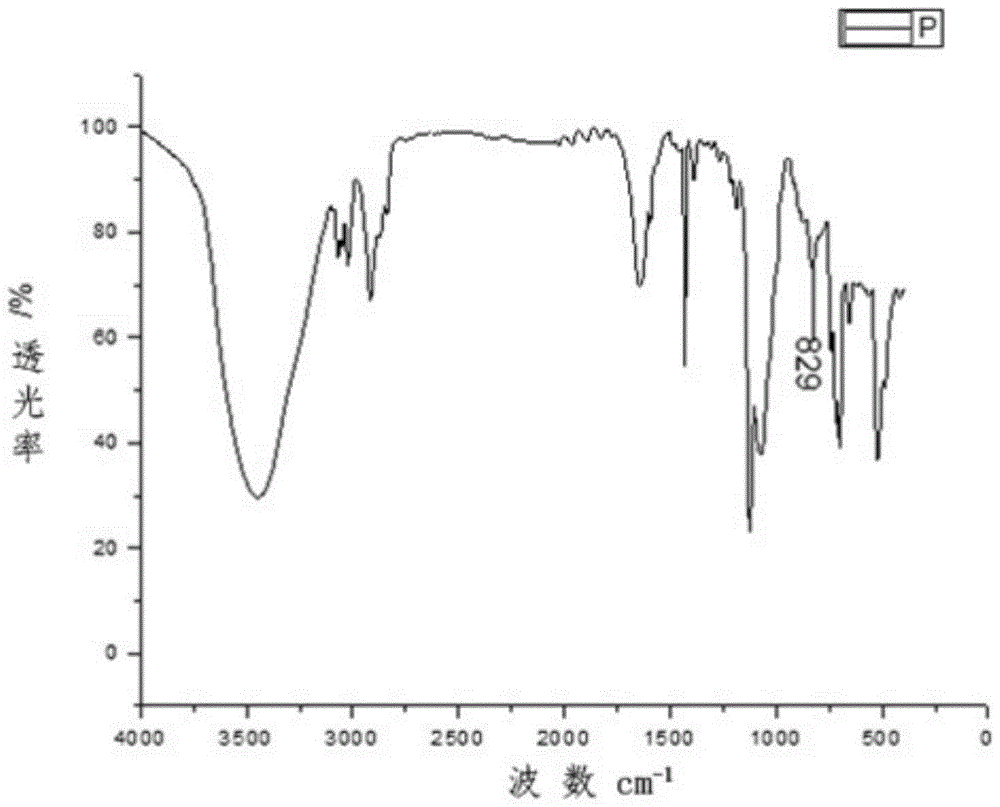

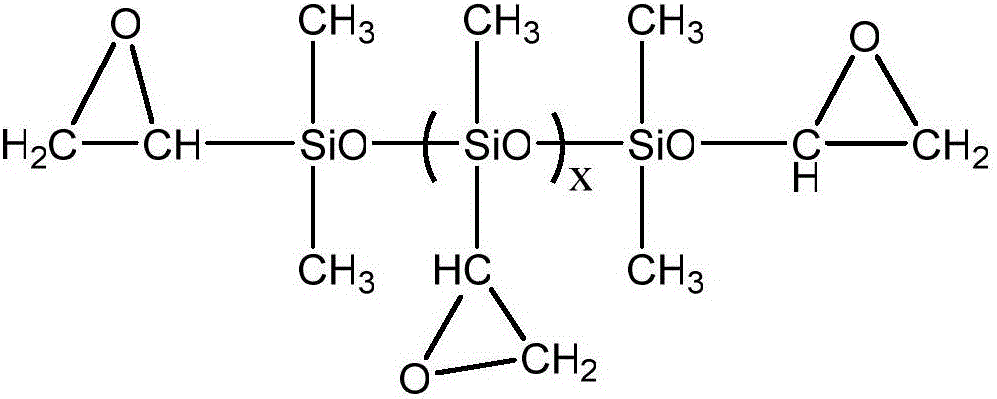

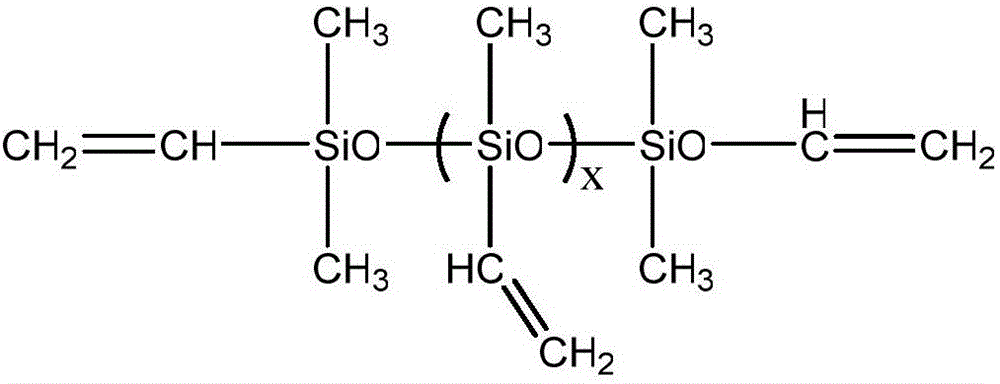

A kind of epoxy polysiloxane and epoxidation preparation method

A technology of epoxy polysiloxane and polyvinyl polysiloxane, which is applied in the field of polymer synthesis, can solve the problems of removing influence, difficult to control catalyst, difficult reaction, etc., so as to improve resistance and avoid interface compatibility. Problems, effects of easy separation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put a thermometer on the reaction vessel, connect the vacuum dehydration device, add 30 parts of octamethylcyclotetrasiloxane, 8 parts of tetramethyltetravinylcyclotetrasiloxane, vinyl 0.4 parts of the double head, the vacuum degree is below -0.090MPa, turn on the heating and magnetic stirring device, raise the temperature to the set initial temperature of 50°C, and remove the water for 0.5h; then add the catalyst tetramethylammonium hydroxide aqueous solution, tetramethylammonium hydroxide The amount of ammonium hydroxide added accounts for 0.03% of the total mass of the mixed monomers. Replace the reflux condenser, raise the temperature of the material in the bottle to a set temperature of 100°C, and polymerize at the set temperature for 5 hours (note: no need at this time) vacuum dewatering device). After the reaction is over, quickly raise the temperature to above 140°C to decompose the catalyst. When the pH of the tail gas is detected to be about 7 with pH test pap...

Embodiment 2

[0037]Put a thermometer on the reaction vessel, connect the vacuum dehydration device, and add 30 parts of octamethylcyclotetrasiloxane, 12 parts of tetramethyltetravinylcyclotetrasiloxane, vinyl 0.6 parts of the double head, the vacuum degree is below -0.090MPa, turn on the heating and magnetic stirring device, raise the temperature to the set initial temperature of 70°C, and remove the water for 1 hour; then add the catalyst tetramethylammonium hydroxide aqueous solution, tetramethylhydrogen The amount of ammonium oxide added accounts for 0.05% of the total mass of the mixed monomers. Replace the reflux condenser, raise the temperature of the material in the bottle to a set temperature of 100°C, and polymerize at the set temperature for 5 hours (note: no vacuum is required at this time) dewatering device). After the reaction is over, quickly raise the temperature to above 140°C to decompose the catalyst. When the pH of the tail gas is detected to be about 7 with pH test pape...

Embodiment 3

[0040] Put a thermometer on the reaction vessel, connect the vacuum pumping and water removal device, add 30 parts of octamethylcyclotetrasiloxane, 10 parts of tetramethyltetravinylcyclotetrasiloxane, and 0.5 parts of vinyl double-head, When the vacuum degree is below -0.090MPa, turn on the heating and magnetic stirring device, raise the temperature to the set initial temperature of 60°C, and remove water for 0.5h; then add the catalyst tetramethylammonium hydroxide aqueous solution, the amount of tetramethylammonium hydroxide added Accounting for 0.04% of the total mass of the mixed monomer, replace the reflux condenser, raise the temperature of the material in the bottle to a set temperature of 110°C, and polymerize at the set temperature for 6 hours (note: no vacuum water removal device is required at this time). After the reaction is over, quickly raise the temperature to above 140°C to decompose the catalyst. When the pH of the tail gas is detected to be about 7 with pH te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com