A kind of high tear-resistant silicone rubber nanocomposite and preparation method thereof

A silicone rubber nano-composite technology, applied in the field of silicone rubber, can solve the problems of weak force of carbon nanotubes, uneven dispersion, weak matrix interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

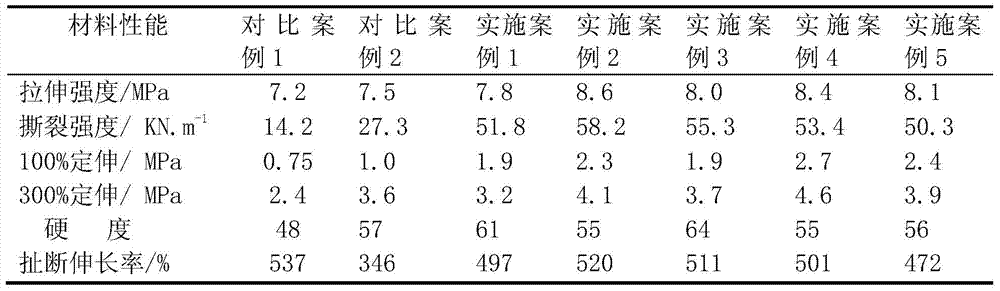

comparative example 1

[0017] Put 100 grams of silicone rubber with a vinyl content of 0.1-0.2% and a molecular weight of 550,000-600,000 on a double-roll mill at room temperature. After the rolls are stabilized, add 40 parts of fumed white carbon black and 5 parts of hydroxyl silicone oil. 1. 0.5 part of dicumyl peroxide, after fully mixing, thin pass 4 times to lower the sheet, then vulcanize on a flat vulcanizing machine with a temperature of 160°C and a pressure of 15MPa. The mechanical properties of the tested material are shown in Table 1:

comparative example 2

[0019] Put 100 grams of silicone rubber with a vinyl content of 0.1-0.2% and a molecular weight of 550,000-600,000 on a double-roll mill at room temperature. After the rolls are stabilized, add 30 parts of fumed white carbon black and 3 parts of hydroxyl silicone oil. , 5 parts of carbon nanotubes, 0.8 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane, after fully mixing, thin pass 4 times to lower the sheet, and then at a temperature of 170 ℃, and the pressure is 15MPa on a flat vulcanizing machine. The mechanical properties of the tested materials are shown in Table 1:

Embodiment example 1

[0021] Put 100 grams of silicone rubber with a vinyl content of 0.1-0.2% and a molecular weight of 550,000-600,000 on a double-roll mill at room temperature. After the rolls are stabilized, add dimethyldiphenylthiuram disulfide 0.6 50 parts of fumed white carbon black, 6 parts of hydroxy silicone oil, 3 parts of carbon nanotubes, 3.5 parts of benzoyl peroxide. Vulcanized on a 15MPa flat vulcanizing machine, the mechanical properties of the tested materials are shown in Table 1:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com