Preparation method and application of bionic gecko extremely progressive rigid-flexible gradient micro-column structure

A progressive, rigid-flexible technology, applied in the field of biomimetic materials, can solve the problems of limited structural stability of the composite micro-pillar aspect ratio, high mismatch stress, difficult interface control, etc., to achieve excellent rough surface compliance and durable adhesion performance, The effect of increasing the maximum aspect ratio to avoid interface problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

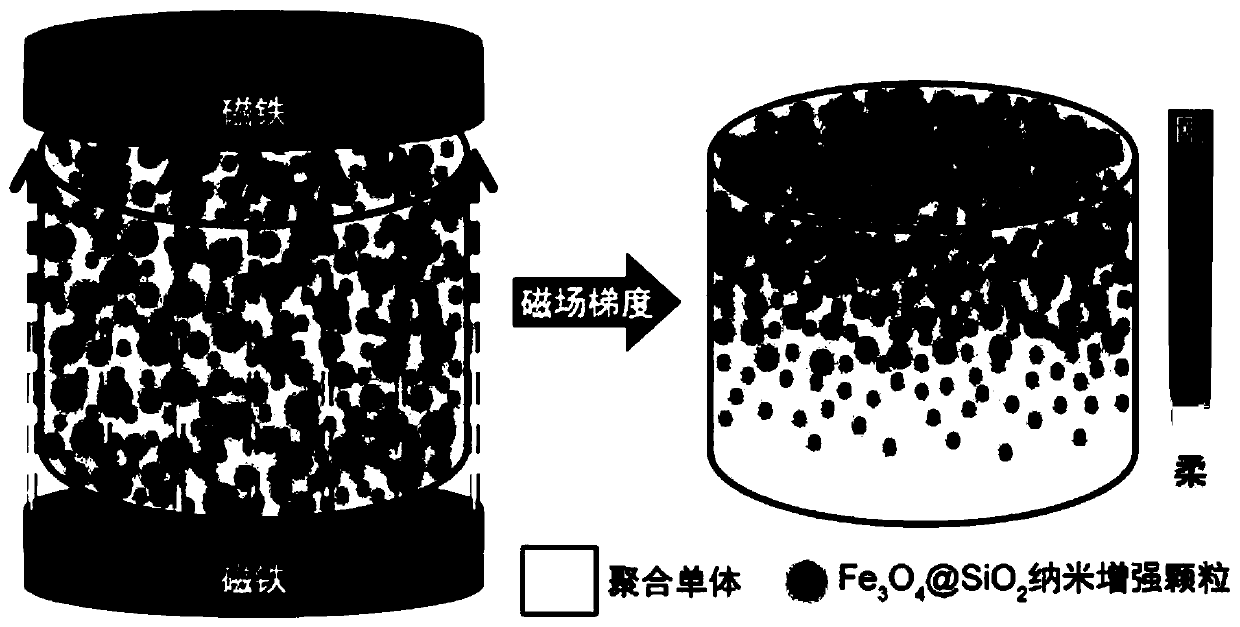

[0037] Controllable Preparation of Matrix and Reinforcing Phase Dual Gradient Polymer-Based Nanocomposites

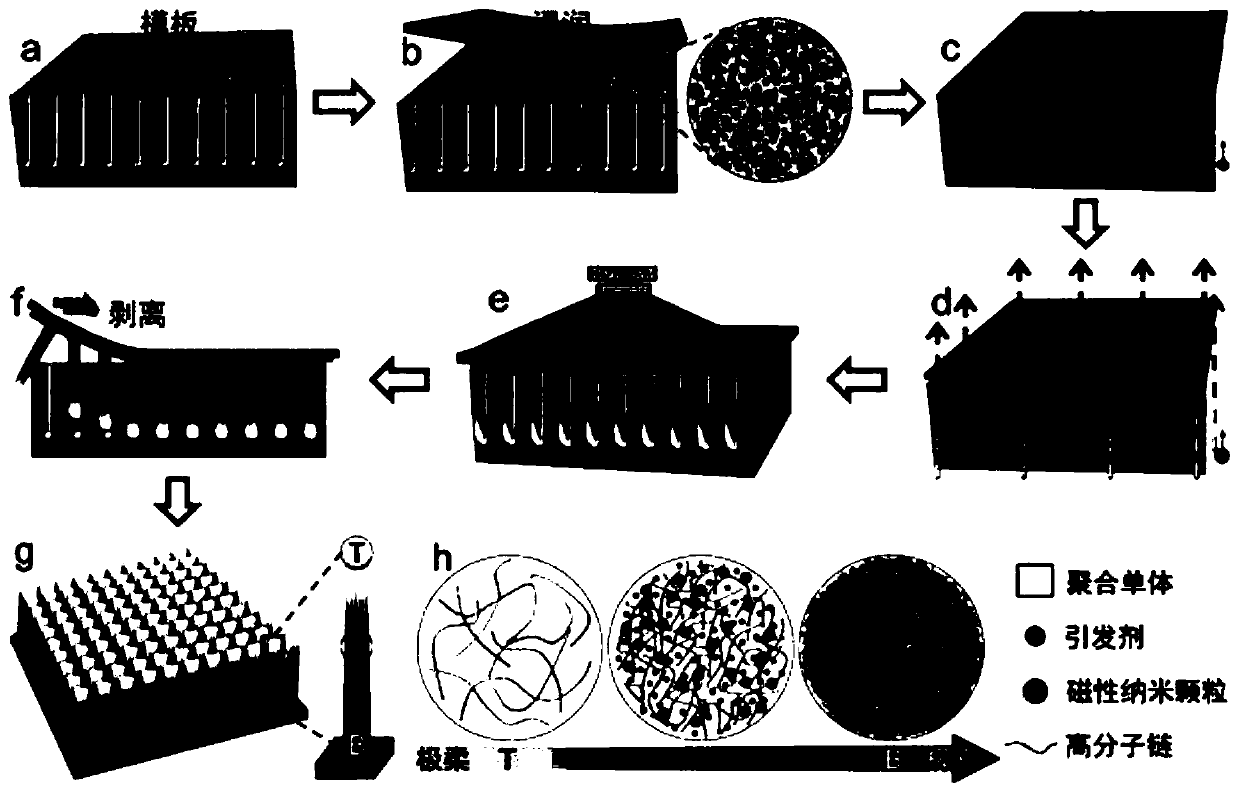

[0038] The invention discloses a preparation method and application of a bionic gecko extremely progressive rigid-flexible gradient micro-column structure. The preparation process is as follows figure 1 shown.

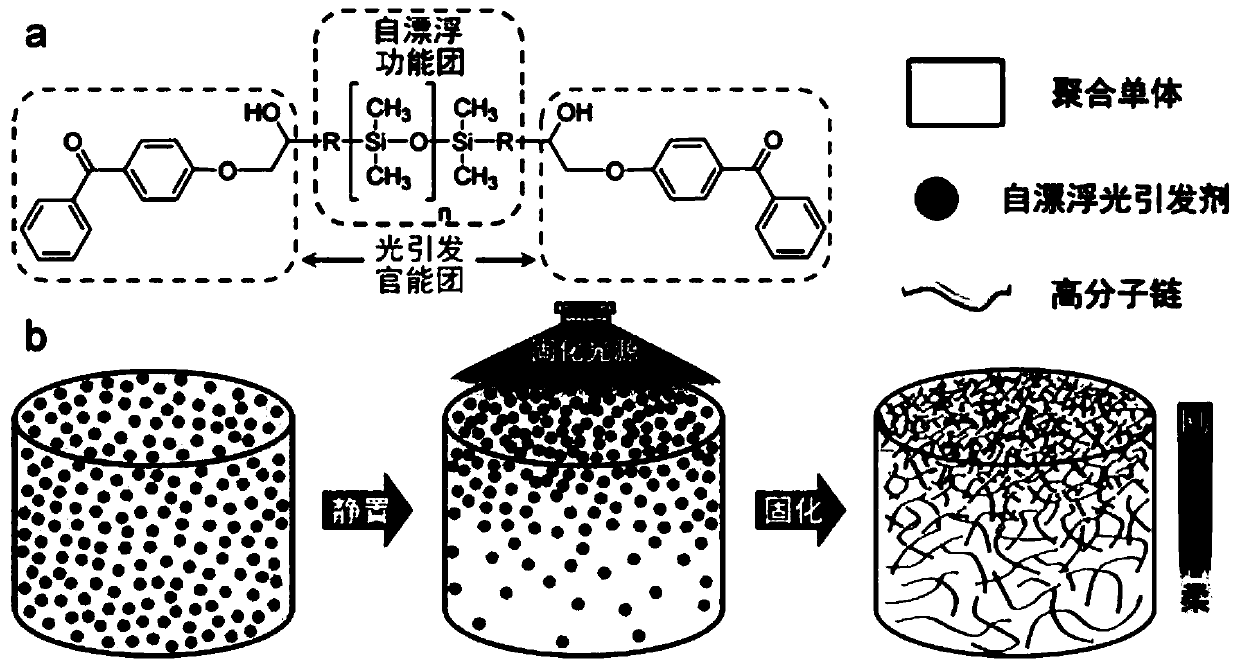

[0039] Step 1: Preparation of self-floating polysiloxane-based photoinitiated crosslinking agent.

[0040] First, HHMP (26.9 g, 0.12 mol), TsCl (19.0 g, 0.10 mol), KOH (22.4 g, 0.40 mol) were dissolved in 300 mL CH 2 Cl 2 in a 500 mL three-necked round bottom flask equipped with a mechanical stirrer and a condenser. Stir at room temperature (25° C.) for 2 h, and rinse with deionized water three times. The organic layer was in Na 2 SO 4 Dry, filter, and vacuum distill. The crude product was purified by silica gel (200-300mesh) column chromatography with ethyl acetate and dichloromethane (volume ratio: 1:20) as the eluent, and the yield was 62.5%. The synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com