Patents

Literature

31results about How to "Change brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel environment-friendly water-based plastic track

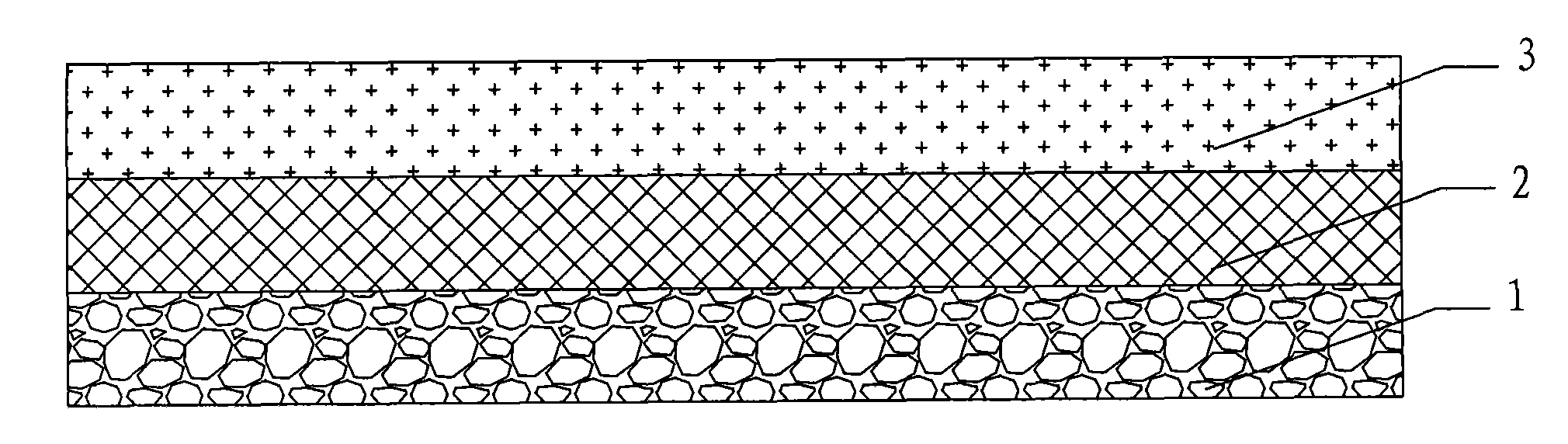

The invention relates to a novel environment-friendly water-based plastic track, which comprises three layers of structures such as a base surface layer, a plastic elastic layer and an antiskid surface layer, wherein the base surface layer is provided with a concrete or asphalt structure; the plastic elastic layer is formed by fully stirring cement, a water-based polymer emulsion, black waste rubber particles of which the particle size is 3 mm, water and an aid, paving the mixture on the base surface layer and solidifying the mixture at the normal temperature of -50 DEG C, and reaches the required thickness; and the antiskid surface layer is formed by fully stirring white cement, a water-based polymer emulsion, water, pigment and an aid to obtain a slurry, paving the slurry on the plastic elastic layer, spraying 30 to 40 mass parts of colorized EPDM particles of which the particle size is 2 to 4 mm, and performing solidification under the condition that the temperature is between the normal temperature and 50 DEG C. The novel environment-friendly water-based plastic track adopts building water-based polymer emulsion modified cement as a binding agent, is nontoxic and environment-friendly, can be used for construction in a moist environment with water, has a low cost, is simple and convenient to operate, is ventilate and hydro-ceramic, has high physical properties, and does not drop particles, and all properties of the novel environment-friendly water-based plastic track reach national standards.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

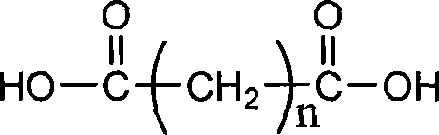

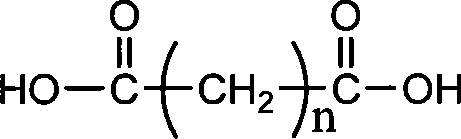

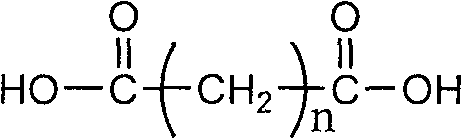

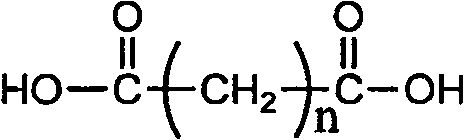

Preparation method of full biodegradation polyester copolymer

The invention belongs to the technological field of the polymer material, particularly relating to a preparation method of the completely biodegradable polyester copolymer. The invention uses the method of the fusion and direct polymerization to prepare the carboxyl-terminated lactic acid prepolymer and then copolymerize with the aliphatic polycarbonate; then the reaction is done in the twin-screw extruder to screw out the extension chain and the good polylactic acid copolymer is made. The concrete steps are: the lactic acid and small-molecule dicarboxylic acid react under the condition with the presence of the catalyst to directly polymerize the carboxyl-terminated lactic acid prepolymer; then the aliphatic polycarbonate diol and the catalyst are added; with the presence of the N2, the reaction is kept for 1 to 10 hours at the temperature of 150 to 200 Celsius system to get the poly lactic acid and polycarbonate copolymer of the low molecular weight; then the reaction is done in the twin-screw extruder at the temperature of 150 to 190 Celsius system to screw out the extension chain; finally the polylactic copolymer of the high molecular weight, toughness and heat resistance is made. The process of the method of the invention is simple and easy in the industrialized production; the copolymer resin product produced by the method is completely biodegradable and the application scope is wide.

Owner:TONGJI UNIV

Method for preparing polylactic acid group block copolymer

The invention belongs to the technological field of polymer material, particularly relating to a preparation method of the poly-lactic acid block copolymer. The invention uses the melting and direct polymerization method to prepare the lactic acid prepolymer, and then uses the chain extension method to prepare the poly lactic acid multi-block copolymer with the high molecular weight. The concrete steps are: first the lactic acid and aliphatic polycarbonate diol are used to react under the condition of the presence of the catalyst and to direct polycondensate to synthesize the hydroxyl-terminated p lactic acid prepolymer; then the chain extender and catalyst are added; with the presence of N2, vacuum; the reaction is kept for 10 to 50 minutes at the temperature of 150 to 300 Celsius system; finally the poly lactic acid multi-block copolymer with the high molecular weight can be made. The process of the method of the invention is simple and easy for the industrialized production; the copolymer resin product produced in the invention is completely biodegradable and the application scope is wide.

Owner:TONGJI UNIV

High-strength and heat-resistant polylactic acid material for 3D printing

ActiveCN104987680AImprove heat resistanceReduce heat warpageAdditive manufacturing apparatusEpoxyAntioxidant

The present invention relates to a high-strength and heat-resistant polylactic acid material for 3D printing, wherein the components comprise, by mass, 100 parts of a L-polylactic acid resin, 1-20 parts of an inorganic filler, 0.01-5 parts of a polycarboxylic acid metal salt, 0.1-5 parts of an amide compound, 0.1-5 parts of a plasticizer, 0.1-1 part of an antioxidant, and 0.1-2 parts of an anti-hydrolyzing agent, wherein the molecular weight of the L-polylactic acid resin is 100000-400000, the anti-hydrolyzing agent is mixing at least one or more than two selected from a Polycarbodiimide compound, a single carbodiimide compound and a compound having an active group epoxy, the inorganic filler is a mixture formed from one or at least two selected from nanometer silica, talc powder, calcium sulfate crystal whisker and mica, and the diameter of the inorganic filler is 0.05-5 [mu]m. According to the present invention, the tensile strength achieves more than or equal to 60 MPa, the bending strength achieves more than or equal to 100 MPa, the Vicat softening temperature is more than or equal to 120 DEGC, the mechanical property and the heat resistance are substantially improved compared with the commonly used PLA, and the practicality and the application range of the PLA supplies are substantially improved.

Owner:中广核三角洲(江苏)塑化有限公司

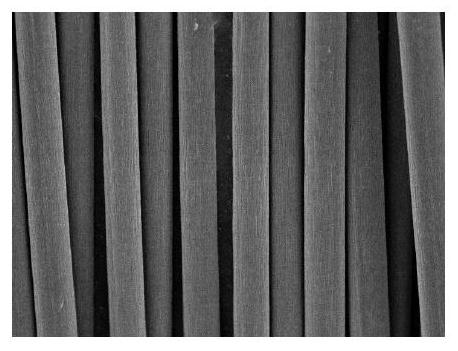

NiTi shape memory alloy bionic nano TiO2 tectorial membrane biology medical embedded material and application

InactiveCN101100738AMake sure not to be importedPrevent splashSurgeryVacuum evaporation coatingTectorial membraneShape-memory alloy

Bio-medical implanting material with biomimetic nano film and its use are both disclosed herewith. The implanting material uses NiTi shape-memory alloy as base with biomimetic nano TiO2 bio-ceramic film of 100-200nm to stop Ni ions liberated in human body liquid. It can be used as implanting device, e.g. tubular support, bone fixer, bone orthotic device, and oral orthodontic material, etc.

Owner:沈阳天贺新材料开发有限公司

Epoxy structure adhesive for rotor blades and preparation method thereof

InactiveCN102329586AMeet application requirementsExtend curing timePolyureas/polyurethane adhesivesEpoxy resin adhesivesPolymer scienceAdhesive

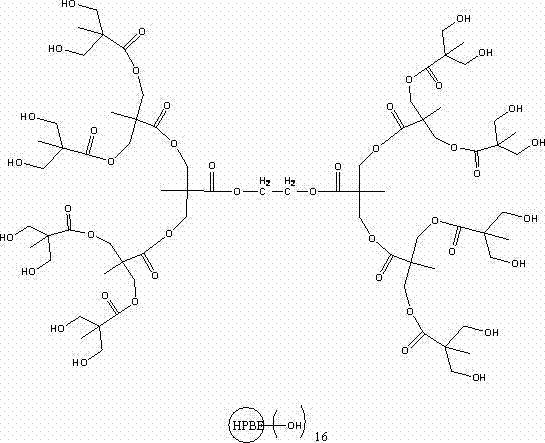

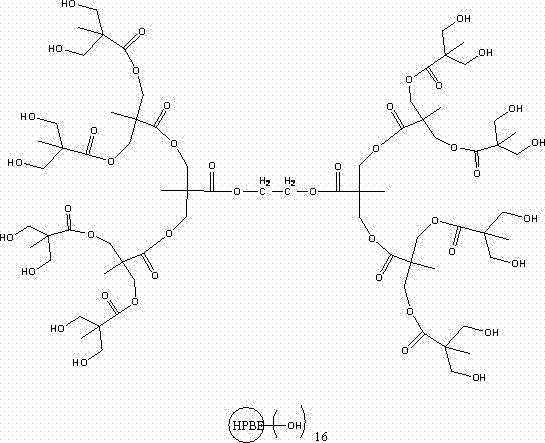

The invention relates to an epoxy structure adhesive for rotor blades and a preparation method thereof. The epoxy structure adhesive for the rotor blades consists of a component A and a component B, of which the proportion by weight is 100:40.5 to 100:49.5; the component A consists of the following materials in percentage by weight: 50 to 68 percent of epoxy resin, 1 to 10 percent of hyperbranched polyurethane acrylate, 10 to 25 percent of thixotropic agent, 0.5 to 12.5 percent of additive and 2 to 10 percent of reactive diluent; the component B consists of the following materials in percentage by weight: 90 to 95 percent of curing agent and 5 to 10 percent of thixotropic agent; and the preparation method for the epoxy structure adhesive for the rotor blades includes the following steps: when in use, the component A and the component B, of which the proportion by weight is 100:40.5 to 100:49.5, are mixed and then are cured under the temperature of 60 DEG C to 70 DEG C for 7 to 10 hours to carry out polymerization reaction, and thereby the epoxy structure adhesive is prepared.

Owner:YANTAI DARBOND TECH

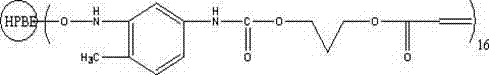

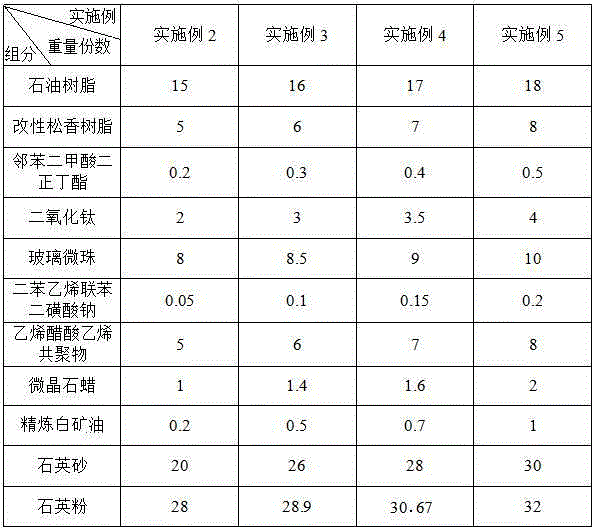

Heat melting high-wear-resistant anti-pollution yellow traffic marking material and preparation method thereof

The invention discloses a heat melting high-wear-resistant anti-pollution yellow traffic marking material and a preparation method thereof. The preparation method is used for preparing the traffic marking material in the technical field of traffics. The heat melting high-wear-resistant anti-pollution yellow traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, glass beads, an ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand, quartz powder and cadmium yellow. The traffic marking material prepared by using the preparation method not only can be used for improving the wear resistance and anti-pollution capacity of a traffic marking, but also can be used for increasing the adhesive force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

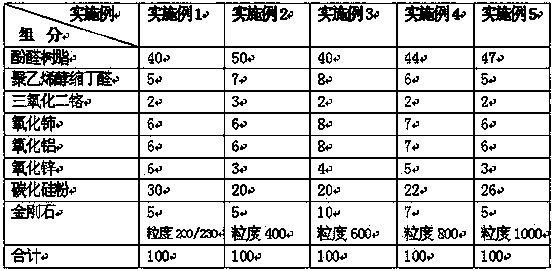

Diamond abrasive of elastic abrasion block used for grinding and polishing nonmetal concave and convex surfaces

InactiveCN104263318AImprove the authenticity rateExtended service lifeOther chemical processesPolyvinyl alcoholCerium oxide

A diamond abrasive of an elastic abrasion block used for grinding and polishing nonmetal concave and convex surfaces is disclosed. The diamond abrasive is characterized in that: the diamond abrasive comprises 40-50% by mass of phenolic resin, 5-8% by mass of polyvinyl butyral, 2-3% by mass of chromic oxide, 6-8% by mass of cerium oxide, 6-8% by mass of aluminium oxide, 3-6% by mass of zinc oxide, 20-30% by mass of silicon carbide and 5-10% by mass of diamond; and the raw materials are fully mixed, subjected to mould pressing and sizing at 156-160 DEG C, and cured at 130-145 DEG C. The diamond abrasive is characterized in that: by adding the polyvinyl butyral, brittleness of the phenolic resin is changed, and flexibility and toughness are enhanced, thus avoiding edge breakage and surface breakage of the abrasive during grinding and polishing, eliminating abrasion scratches caused by scratches of ceramic glazes by edge breakage points and surface breakage points of the abrasive and prolonging the service lifetime of the abrasion block.

Owner:沈衡平

Metal repair adhesive for machining

InactiveCN103102855AImprove cohesive strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phasePolyamide

The invention relates to a metal repair adhesive for machining, and belongs to the field of mechanical processing technology. The invention provides a machinable metal repair adhesive. The adhesive is composed of one component comprising by weight 25-35 parts of bisphenol A diglycidyl ether, 0.3-0.7 part of organic polysiloxane,48-65 parts of a metal powder, 2-12 parts of gaseous phase white carbon black, 30-50 parts of a curing agent, 25-45 parts of a low-molecular polyamide resin and 15-25 parts of gaseous phase silica. Compared with the prior art, the invention has the following advantages: 1, the metal repair adhesive has high bond strength and hardness; 2, after curing, the hardness and strength can meet the requirements of machining; and 3, the repair adhesive provided by the invention can be bonded to a metal surface with oil or water, and can cure in oil or water.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Carbon fiber reinforced gypsum board and preparation method thereof

The invention relates to a carbon fiber reinforced gypsum board and a preparation method thereof. The technical problem that a gypsum board is low in rupture strength, poor in compressive strength andpoor in waterproof performance in the prior art is solved. The carbon fiber reinforced gypsum board provided by the invention is prepared from the following raw material components: 70-110 parts of agypsum powder, 20-30 parts of diatomite, 5-10 parts of glucose, 4-12 parts of an admixture, 160-200 parts of water and 20-30 parts of chopped carbon fibers. Moreover, the invention further provides apreparation method of the carbon fiber reinforced gypsum board. The carbon fiber reinforced gypsum board disclosed by the invention is widely applied to the technical field of building materials.

Owner:威海南海碳材料科技研究院有限公司

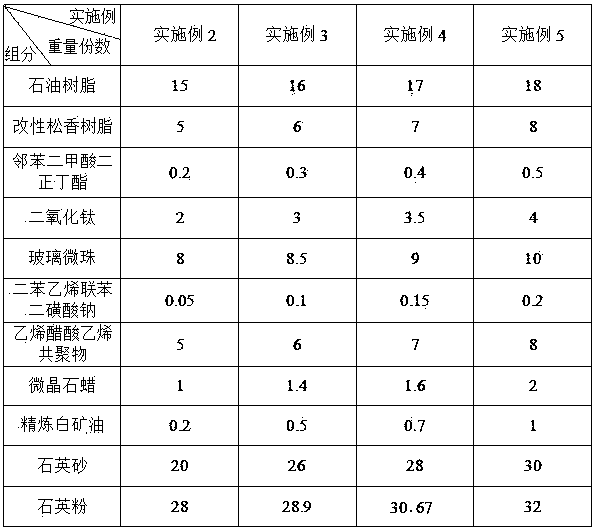

Heat-fused highly-wear-resisting anti-pollution white traffic marking material and preparation method thereof

ActiveCN103951931AGood weather resistanceImprove wear resistanceMicrocrystalline waxMaterials science

The invention discloses a heat-fused highly-wear-resisting anti-pollution white traffic marking material and a preparation method thereof, and the preparation method is used for manufacturing the traffic marking material in the traffic technical field. The heat-fused highly-wear-resisting anti-pollution white traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl ortho-phthalate, titanium dioxide, glass bead, stilbene biphenyl sodium disulfonate, ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand and quartz powder. The traffic marking material prepared by adopting the preparation method disclosed by the invention not only can be used for improving the wear resistance and anti-pollution capacity of the traffic marking, but also strengthening the adhesion force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

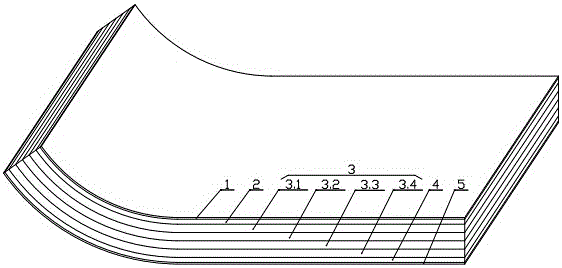

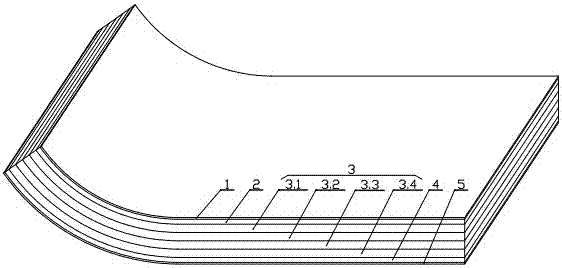

Arc-shaped bridge membrane laminating as-cast finish template and production process thereof

ActiveCN105058941AAchieve "softening" effectTo achieve the effect of softeningLaminationLamination apparatusAdhesiveWhole body

The invention relates to an arc-shaped bridge membrane laminating as-cast finish template and a production process thereof. The template comprises melamine impregnated paper, poplar veneers and a core curtain; the arc-shaped bridge membrane laminating as-cast finish template sequentially comprises upper-layer melamine impregnated paper, an upper-layer poplar veneer, the core curtain, a lower-layer poplar veneer and lower-layer melamine impregnated paper from top to bottom; a blank assembling sequence of the core curtain from top to bottom is a long curtain, a long curtain, a short curtain and a long curtain, namely the core curtain totally comprises four layers; the upper-layer poplar veneer is coated with a modified adhesive and is vertically arrayed; the lower-layer poplar veneer is coated with the modified adhesive and is transversely arrayed; and all the layers are compounded into a whole body through gluing and hot pressing. The production process comprises: (1) preparing the melamine impregnated paper; (2) preparing the core curtain; (3) preparing the poplar veneers; (4) assembling a blank of the template; and (5) gluing, hotly pressing and molding. According to the template, a blank assembling structure is adjusted and a surface adhesive type is improved to realize a softening effect, so that the effect that the template can be randomly bent and is not cracked, deformed and broken is realized; and the effect of a manufactured bridge is good and the requirements needed by a curved-surface bridge are met.

Owner:FUJIAN LONGDA BAMBOO +1

Plastic special for fluorescent switch buttons

InactiveCN106609018AImprove flame retardant performanceImprove the lubrication effectSodium metasilicateFluorescence

The invention discloses a plastic special for fluorescent switch buttons. The plastic comprises the following components by weight: 40-50 parts of polyvinyl chloride, 0.5-2 parts of an antioxidant, 3-6 parts of a fluorescent brightener, 2-4 parts of aluminum hydroxide, 1-4 parts of magnesium hydroxide, 5-10 parts of sodium metasilicate pentahydrate, 1-4 parts of fatty alcohol-polyoxyethylene ether, 3-10 parts of a stabilizer, 2-5 parts of a mold release agent, 2-4 parts of a preservative, 30-40 parts of calcium carbonate, 2-4 parts of a penetrating agent, and 1-3 parts of an anti-sedimentation agent. The plastic provided by the invention has the advantages of good fluorescent effect, convenient use, high flame retardance and shock resistance, lubricity and water resistance, and low production cost.

Owner:CHUZHOU PINZHIDA ELECTRIC TECH

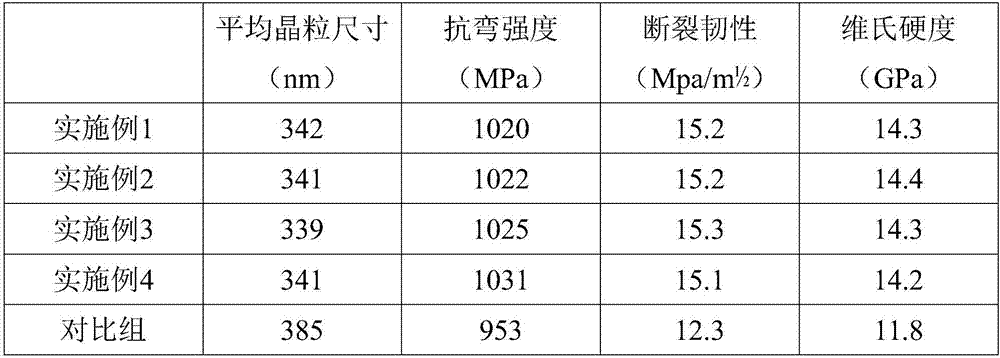

Ceramic electric kettle and preparation method thereof

The invention discloses a ceramic electric kettle and a preparation method thereof and relates to the technical field of electric kettles. The electric kettle body is prepared from, by weight, 80-100parts of silicon dioxide, 30-35 parts of aluminium oxide, 12-18 parts of titanium dioxide, 8-15 parts of zirconium oxide, 12-15 parts of calcium carbonate, 6-12 parts of magnesium carbonate, 19-27 parts of talc, 30-60 parts of argil, 20-40 parts of kaolin, 10-16 parts of silicon nitride, 5-10 parts of titanium carbide, 3-8 parts of reinforcing agent, 7-10 parts of stabilizer, 1.6-1.9 parts of glaze and 40-55 parts of water; the reinforcing agent is prepared from, by weight, 20-25 parts of glass fiber, 30-45 parts of polyvinyl alcohol fiber, 10-15 parts of polybutylene terephthalate, 8-14 partsof phenolic foam, 12-18 parts of yttrium oxide and 15-18 parts of chromium carbide. The prepared ceramic electric kettle has smaller grain size and higher bending strength, fracture toughness and hardness, has great anti-embrittlement effect, and has prominent contribution for prolonging the service life of the ceramic electric kettle.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

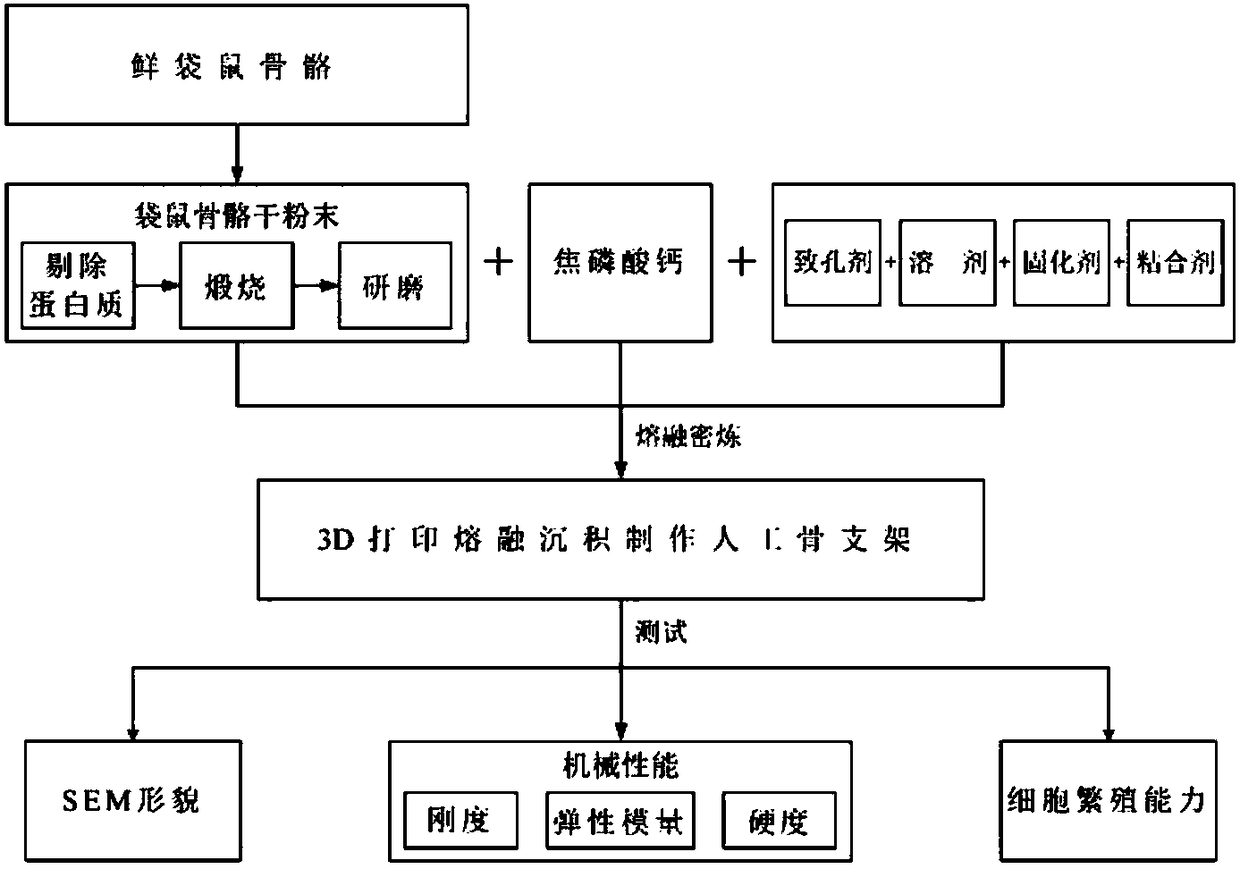

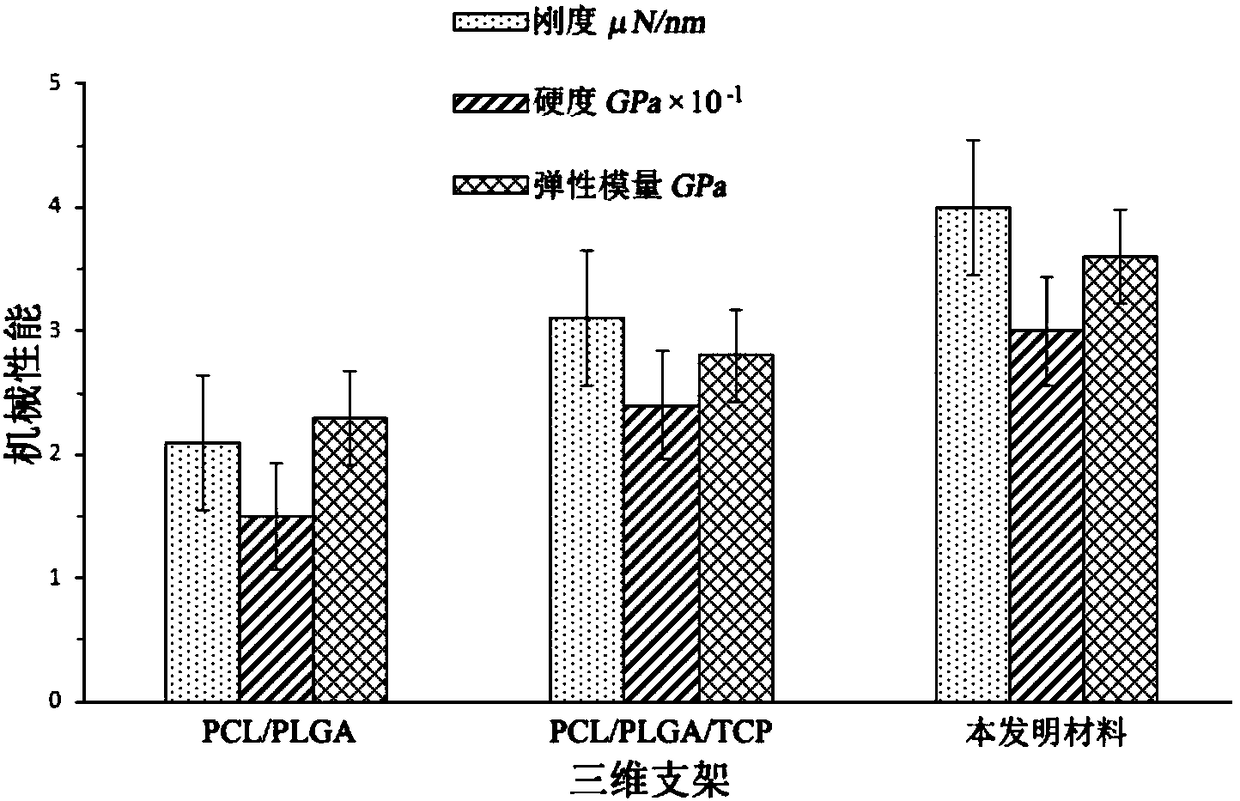

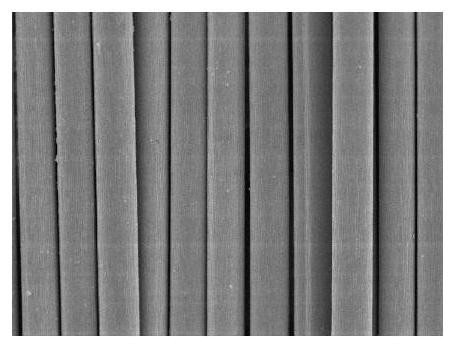

A kind of artificial bone scaffold composite material based on kangaroo bone and its preparation method

ActiveCN105536065BHigh hardnessHigh modulus of elasticityTissue regenerationProsthesisGlycolic acidCalcium pidolate

The invention discloses an artificial bone scaffold composite material based on kangaroo bone and a preparation method of the artificial bone scaffold composite material. The material is a blended material composed of kangaroo bone powder, calcium pyrophosphate Ca2P2O7, a pore-forming agent, a solvent, a catalytic curing agent and a bonding agent. The method comprises the following steps of adding dry kangaroo bone powder, the calcium pyrophosphate, the pore-forming agent, the solvent, the catalytic curing agent and the bonding agent into a mixing-type torque rheometer for fusion and smelting till a torque is balanced, thereby obtaining the artificial bone scaffold composite material based on the kangaroo bone; finally obtaining an artificial bone scaffold through a 3D (three-dimensional) fused deposition modeling technology. The artificial bone scaffold based on the kangaroo bone disclosed by the invention has the advantages that the biocompatibility is kept and the mechanical defects are conquered at the same time; compared with the existing PLA / PLGA, PLA / PLGA / TCP (polylactic acid / poly(lactic-co-glycolic acid) / tertiary calcium phosphate) artificial bone scaffolds, the rigidity, hardness and elastic modulus of the artificial bone scaffold based on the kangaroo bone are all enhanced.

Owner:杭州夏尔电子科技有限公司

A preparation method of burning oxidized carbon fiber reinforced phenolic resin friction composite material

The invention discloses a method for preparing an oxidized carbon fiber-reinforced phenolic resin friction composite material by a burning method. First, the carbon fibers are burned with butane gas for 5-60 minutes to obtain carbon fibers with a large number of oxygen-containing functional groups such as -COOH and -OH on the surface. . The calcined carbon fibers were then combined with APTES-modified β-Si 3 N 4 , phenolic resin and curing agent (H256) are mixed with pre-dipping liquid in a mass ratio of 30-40:60-70. After removing the solvent from the prepreg, hot-press curing at a temperature of 130-150° C., a hot-pressing time of 20 minutes, and a pressure of 5 MPa to obtain a fired carbon oxide fiber / phenolic resin friction composite material. The sample was subjected to friction and wear test, and its thermal conductivity was 3.06W m ‑1 k ‑1 , the coefficient of kinetic friction reaches 0.13, and the wear rate is as low as 1.14×10 ‑8 mm 3 / Nm. The friction composite material exhibits excellent tribological properties, and has a simple preparation process, low cost and no pollution.

Owner:CHANGCHUN UNIV OF TECH

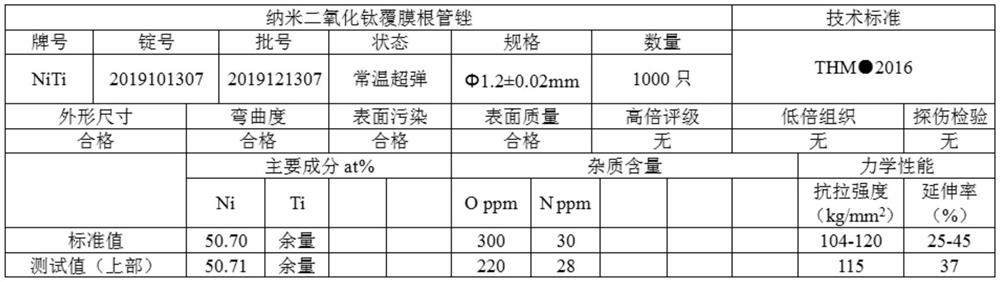

Nano-titanium-dioxide coated root canal file and preparation method thereof

PendingCN111850497AIncrease biological functionGood workmanshipTeeth fillingVacuum evaporation coatingShape-memory alloyTitanium

The invention relates to the field of biomedical metal products, in particular to a nano-titanium-dioxide coated root canal file and a preparation method thereof. The nano-titanium-dioxide coated rootcanal file takes nickel-titanium shape memory alloy as a matrix, a nano titanium dioxide coating film is prepared on the surface of the matrix, and the thickness of the nano titanium dioxide coatingfilm is 60 nm-100 nm. The nano-titanium-dioxide coated root canal file adopts the Ni-Ti shape memory alloy and has biological functionality, and the mechanical property of the nano-titanium-dioxide coated root canal file is suitable for a human body; and the nano-titanium-dioxide coating film on the surface of the root canal file has biocompatibility of biological ceramic, is non-toxic, has good biological safety, and has great advantages and application prospects. A film coating method adopted in the preparation method of the nano-titanium-dioxide coated root canal file is simple in process,but the film coating effect is good. The nano-titanium-dioxide coated root canal file is safe to use in medicine and good in practicability.

Owner:山西嘉文生物科技有限公司

A kind of hot-melting high wear-resistant and anti-pollution white traffic marking material and preparation method thereof

The invention discloses a hot-melt high wear-resistant and anti-pollution white traffic marking material and a preparation method thereof, which are used for making traffic marking materials in the field of traffic technology 。 Including the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, titanium dioxide, glass microspheres, sodium distyrene biphenyl disulfonate, ethylene vinyl acetate copolymer, microcrystalline paraffin, refined white Mineral oil, quartz sand, quartz powder. The traffic marking material prepared by the invention can not only improve the wear resistance and anti-pollution ability of the traffic marking, but also enhance the adhesion of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

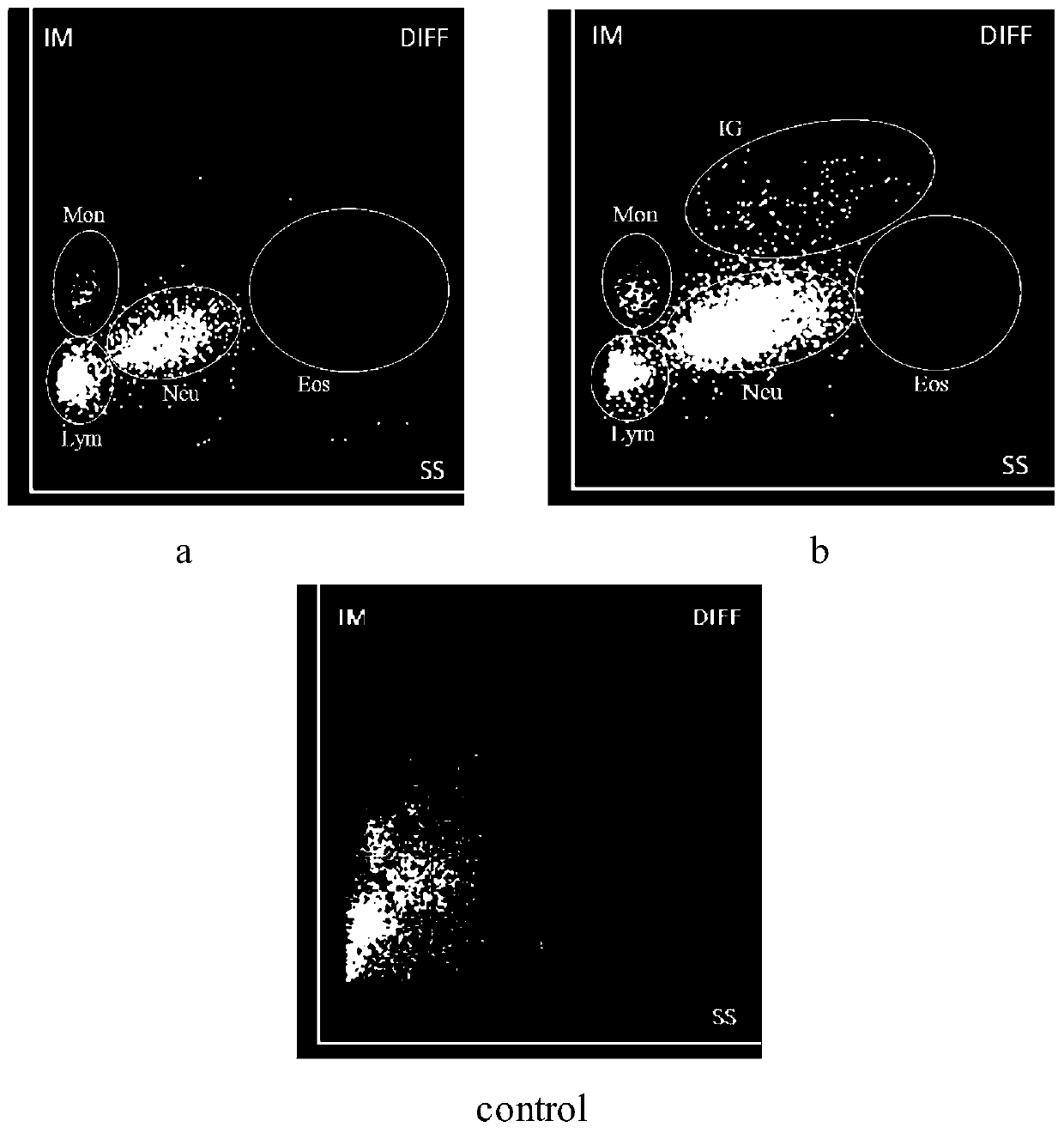

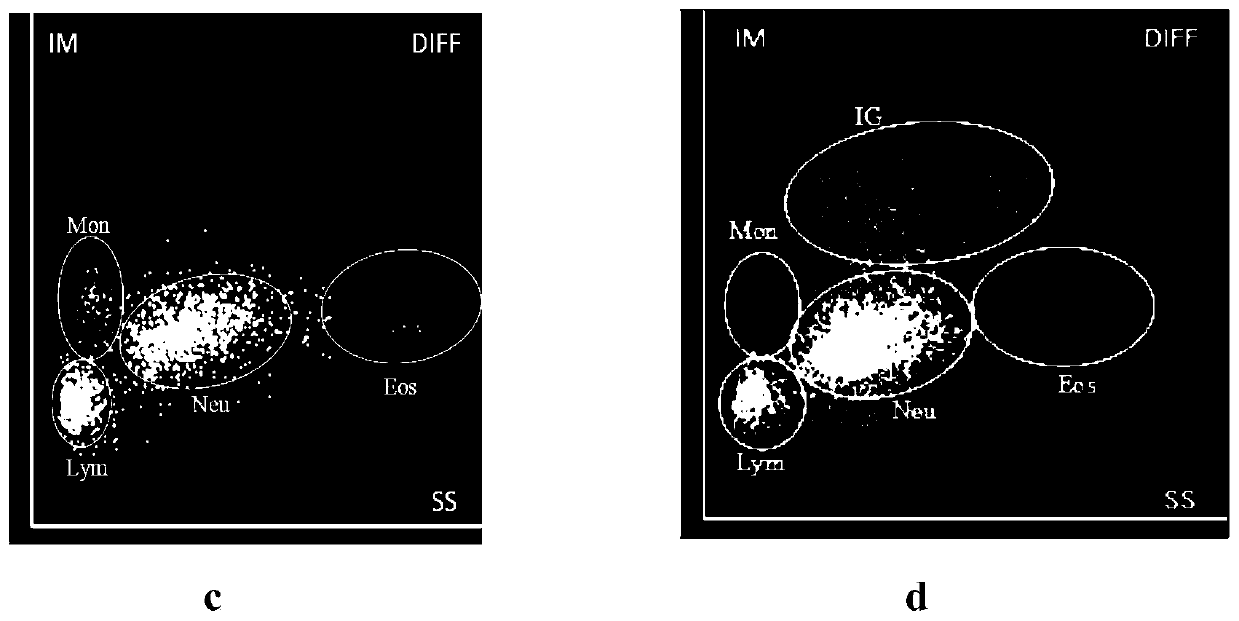

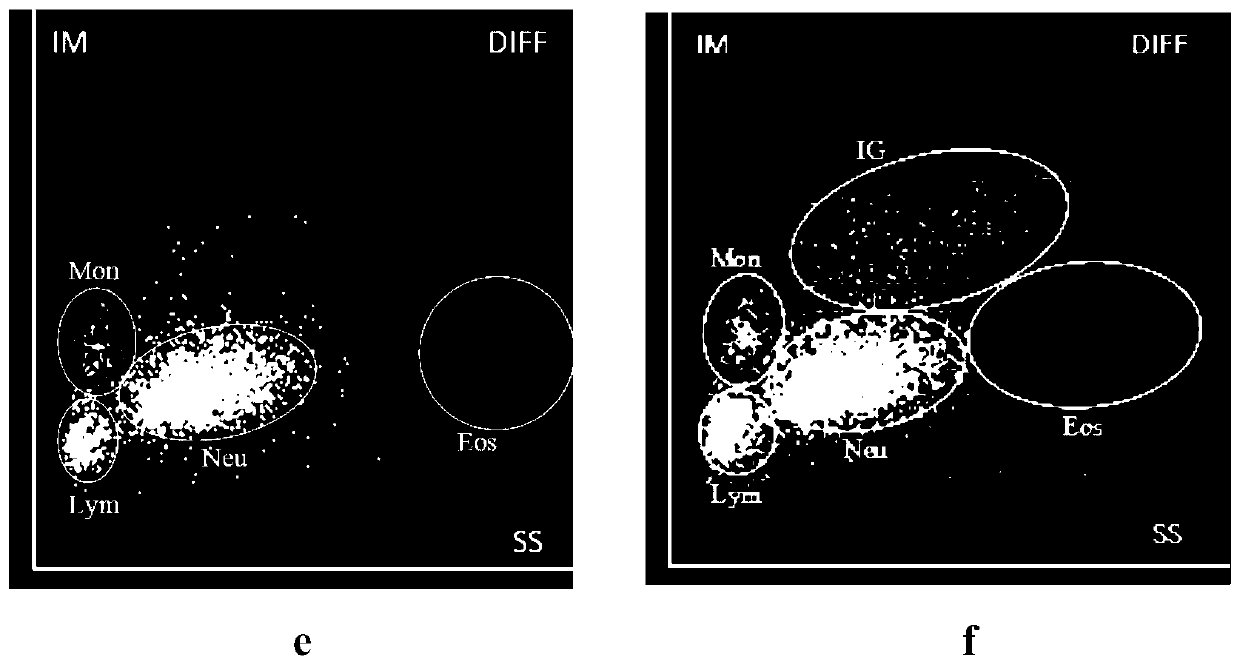

Leukocyte classification reagent

InactiveCN111024563AChange brittlenessEfficient separationBiological particle analysisIndividual particle analysisBasophiliaWhite blood cell

The invention relates to the technical field of in vitro diagnosis, and discloses a leukocyte classification reagent. The leukocyte classification reagent comprises a polyoxyethylene type nonionic surfactant, a polyol type nonionic surfactant, a buffer solution, a conductivity supplement, an osmotic pressure regulator and a preservative. The reagent provided by the invention is simple in formula and dye-free, the main components only comprise two specific nonionic surfactants, and the defects of excessive cell damage or too small size and too large distribution span of the same kind of cells and failure in effective classification which are possibly caused by other reagents are avoided. According to the present invention, with the reagent, leukocytes can be divided into monocytes, lymphocytes, neutrophils (including basophils) and eosinophils with clear boundaries, and juvenile granulocytes can be classified.

Owner:SONOSCAPE MEDICAL CORP

Processing technology of cotton felt

ActiveCN109594191AReduced service lifeThe rebound rate is maintainedNon-woven fabricsFiberCooking & baking

The invention discloses a processing technology of cotton felt. The processing technology of the cotton felt comprises the following steps: (1), cotton blending, wherein the ratio of PET to hollow fiber to LPET is 30%:40%:30%; (2), cotton mixing; (3), opening; (4), carding; (5), cotton laying; (6), hot baking, wherein the temperature is maintained at 220-250 DEG C, and the fan is controlled at 1200 + / - 200 rev / min; (7), rolling, wherein the thickness of the cotton felt is controlled at 10 + / - 2mm; (8), fan cooling: normal temperature; and (9), cutting and shipping. The cotton felt produced bythe processing technology of the cotton felt provided by the invention is small in volume and convenient to transport, and can be reused after being restored to the original state by heating.

Owner:翰诠特种纺织品(平湖)有限公司

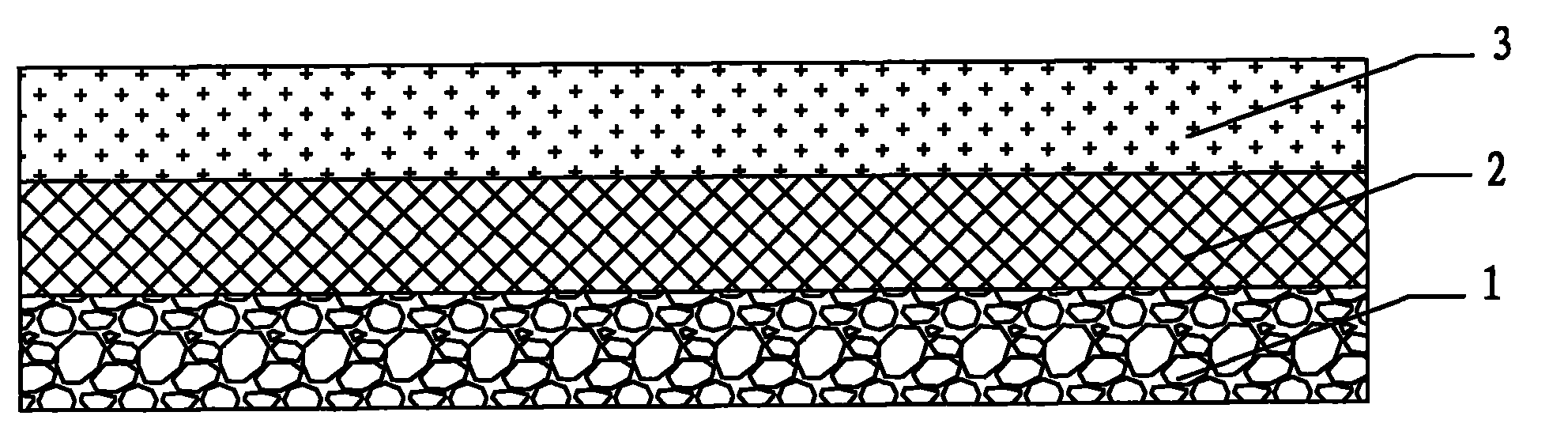

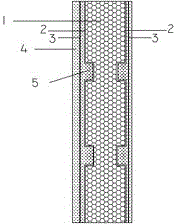

A permanently modified phosphogypsum composite thermal insulation formwork and its manufacturing method

InactiveCN104652697BChange acidityChange brittlenessSolid waste managementClimate change adaptationEmulsionThermal insulation

The invention relates to a permanently modified phosphogypsum composite thermal insulation template and a manufacturing method thereof. The composite thermal insulation formwork is prepared by coating the outside of the extruded board (1) with an interface agent (2), then coating the outside with a modified phosphogypsum slurry (4), and filling the middle of the modified phosphogypsum slurry with a reinforcing material (3). Modified phosphogypsum slurry is made by mixing calcined phosphogypsum powder, cement, fly ash, quicklime, slag micropowder, vitrified microspheres, latex powder, water reducer, retarder, etc. in a certain proportion and then mixed with water. The invention has the advantages of simple preparation process, fast forming, large output, time-saving, labor-saving and labor-saving, and most of the raw materials used are solid waste, which conforms to national policies, is energy-saving and environmentally friendly, and has remarkable economic benefits.

Owner:UNIV OF JINAN

Metal bonding agent used in machining

InactiveCN109988532AHigh hardnessHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phasePolyamide

The invention discloses a metal bonding agent used in machining, and belongs to the technical field of machining. The metal bonding agent used in machining is composed of one component; the componentis composed of, by weight, bisphenol A diglycidyl ether 25-35 parts, organopolysiloxane 0.3-0.7 part, metal powder 48-65 parts, gas-phase white carbon black 2-12 parts, a curing agent 30-50 parts, lowmolecular polyamide resin 25-45 parts, and fumed silica 15-25 parts. Compared with the prior art, the metal bonding agent has the following advantages: 1, the bond strength and hardness are very high; 2, the hardness and strength after curing are capable of meeting the requirements of mechanical processing; and 3, the metal binding agent can be used for binding on metal surfaces with oil or water, and curing in oil or water can be realized.

Owner:谭磊

NiTi shape memory alloy bionic nano TiO2 tectorial membrane biology medical embedded material and application

InactiveCN100507070CGood workmanshipIncrease elasticitySurgeryVacuum evaporation coatingTectorial membraneShape-memory alloy

Bio-medical implanting material with biomimetic nano film and its use are both disclosed herewith. The implanting material uses NiTi shape-memory alloy as base with biomimetic nano TiO2 bio-ceramic film of 100-200nm to stop Ni ions liberated in human body liquid. It can be used as implanting device, e.g. tubular support, bone fixer, bone orthotic device, and oral orthodontic material, etc.

Owner:沈阳天贺新材料开发有限公司

Film-coated clean-water formwork for arc-shaped bridges and its production process

ActiveCN105058941BAchieve "softening" effectTo achieve the effect of softeningLaminationLamination apparatusAdhesiveWhole body

The invention relates to an arc-shaped bridge membrane laminating as-cast finish template and a production process thereof. The template comprises melamine impregnated paper, poplar veneers and a core curtain; the arc-shaped bridge membrane laminating as-cast finish template sequentially comprises upper-layer melamine impregnated paper, an upper-layer poplar veneer, the core curtain, a lower-layer poplar veneer and lower-layer melamine impregnated paper from top to bottom; a blank assembling sequence of the core curtain from top to bottom is a long curtain, a long curtain, a short curtain and a long curtain, namely the core curtain totally comprises four layers; the upper-layer poplar veneer is coated with a modified adhesive and is vertically arrayed; the lower-layer poplar veneer is coated with the modified adhesive and is transversely arrayed; and all the layers are compounded into a whole body through gluing and hot pressing. The production process comprises: (1) preparing the melamine impregnated paper; (2) preparing the core curtain; (3) preparing the poplar veneers; (4) assembling a blank of the template; and (5) gluing, hotly pressing and molding. According to the template, a blank assembling structure is adjusted and a surface adhesive type is improved to realize a softening effect, so that the effect that the template can be randomly bent and is not cracked, deformed and broken is realized; and the effect of a manufactured bridge is good and the requirements needed by a curved-surface bridge are met.

Owner:FUJIAN LONGDA BAMBOO +1

Bonding material for steel surfaces and asphalt concrete

ActiveCN104449427BDispersedHigh modulusNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyamideAccelerant

A bonding material applied to a steel surface and bituminous concrete comprises a component A and a component B at the ratio of 2 to 1, wherein the component A comprises the following ingredients in parts by weight: 2.5-3 parts of an active environment-friendly thinner, 75-90 parts of epoxy resin E51, 5-8 parts of a reactive diluent 501, 2-5 parts of dipropylene glycol and 8-12 parts of an epoxy resin flexibilizer; the component B comprises the following ingredients in parts by weight: 4-6 parts of an active environment-friendly thinner, 8-12 parts of a polyamide curing agent 651, 35-50 parts of a modified amine hardener, 0.8-1.2 parts of an accelerant MP-30, 1.2-1.8 parts of a silane coupling agent Si-69 and 4-6 parts of magnesium oxide. The bonding material has the advantages of being convenient in construction, high in bonding strength, high in impact resistance and high in damage resistance and has the effects of being high in tensile strength, shearing resistance, heat resistance, water resistance and rust resistance.

Owner:辽宁瑞德公路科技有限公司

Strong-strength 3D printing PLA material

ActiveCN106243655AImprove heat resistanceReduce heat warpageAdditive manufacturing apparatusAntioxidantCarboxylic acid

The invention discloses a strong-strength 3D printing PLA material, which comprises the following components in parts by mass: 100 parts of poly-L-lactic acid resin, 1 to 20 parts of an inorganic filler, 0.01 to 5 parts of metal polycarboxylate, 0.1 to 5 parts of an amide compound, 0.1 to 5 parts of a plasticizer, 0.1 to 1 part of an antioxidant and 0.1 to 2 parts of a hydrolysis resistant agent, wherein the hydrolysis resistant agent is at least one of a polycarbodiimide compound, a monocarbodiimide compound and an acrylic copolymer with an active epoxide group; the inorganic filler is one or a mixture formed by at least two of nano silica, talc powder, a calcium sulfate whisker and mica, and the diameter of the inorganic filler is 0.05 to 10 [mu]m. According to the strong-strength 3D printing PLA material, the mechanical performance can also be improved, the tensile strength of the material reaches 63 MPa or above, the brittleness of PLA is changed, and higher pressure and wear can also be born.

Owner:中广核高新核材科技(苏州)有限公司

Processing technology of cotton felt

ActiveCN109594191BReduced service lifeThe rebound rate is maintainedNon-woven fabricsHollow fibreFiber

Owner:翰诠特种纺织品(平湖)有限公司

Thermosetting plastic for air conditioner internal unit

The invention discloses a thermosetting plastic for an air conditioner internal unit. The thermosetting plastic comprises, by weight, 40-50 parts of phenolic resin, 0.5-2 parts of antioxidants, 3-6 parts of coloring agents, 5-10 parts of sodium metasilicate pentahydrate, 5-12 parts of polyoxyethylene-polyoxypropylene copolymer, 3-6 parts of tribasic lead carbonate, 1-4 parts of dimethyl phosphite, 2-5 parts of mould release agents, 2-4 parts of preservatives, 30-40 parts of fillers and 2-4 parts of penetrating agents. The thermosetting plastic is high in heat stability, low in aging speed and long in service life, colors can be adjusted, so that attractiveness of a finished product is enhanced, and production cost is low.

Owner:CHUZHOU PINZHIDA ELECTRIC TECH

Preparation method of full biodegradation polyester copolymer

ActiveCN100558787CChange brittlenessImprove mechanical propertiesPolymer scienceBiodegradable product

The invention belongs to the technical field of polymer materials, and in particular relates to a preparation method of a fully biodegradable polyester copolymer. The present invention adopts the method of melt direct polycondensation to prepare the carboxyl-terminated lactic acid prepolymer, and then carries out copolymerization with aliphatic polycarbonate diol, and then carries out reaction extrusion chain extension in a twin-screw extruder, and the preparation performance Good polylactic acid copolymer. The specific steps are: lactic acid and small molecule dibasic acid are reacted and directly polycondensed under catalyst conditions to form a carboxyl-terminated lactic acid prepolymer, then add aliphatic polycarbonate diol and catalyst, and vacuumize under N2 atmosphere, at 150 At ~200°C, react for 1-10 hours to obtain low-molecular-weight polylactic acid / polycarbonate copolymer, and then perform reaction extrusion chain extension in a twin-screw extruder at 140-190°C to finally obtain high-molecular-weight Polylactic acid copolymer with good toughness and heat resistance. The method of the invention has simple process and is easy for industrialized production, and the prepared copolymer resin product can be completely biodegraded and has wide application fields.

Owner:TONGJI UNIV

A hot-melt high wear-resistant and anti-pollution yellow traffic marking material and its preparation method

ActiveCN103980747BNo color changeGood weather resistanceCoatingsMicrocrystalline waxDi n butyl phthalate

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com