Preparation method of full biodegradation polyester copolymer

A copolymer and fully degradable technology, which is applied in the field of preparation of fully biodegradable polyester copolymers, can solve the problems of polylactic acid toughness and other problems, and achieve the effects of excellent mechanical properties, simple process, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

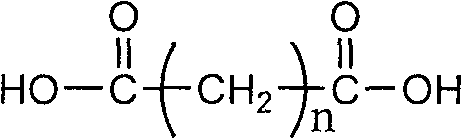

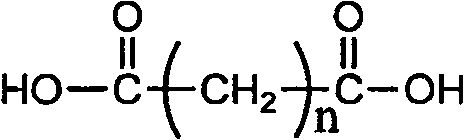

[0023] (1) Dehydrate 400g of L-lactic acid in a reactor at 100°C, then add 20g of succinic acid, vacuum, and perform polycondensation under the action of 0.5g of stannous octoate as a catalyst. The pressure in the reactor is 1000Pa , The temperature is 90 ℃, react for 10 hours, then the pressure in the reactor is reduced to below 100 Pa, the reaction temperature is increased to 150 ℃, and the reaction is continued for 15 hours to obtain M w = 8×10 2 ~3.0×10 4 The carboxyl-terminated lactic acid prepolymer;

[0024] (2) Add the carboxyl-terminated lactic acid prepolymer obtained in step (1) and 200 g of polypropylene carbonate glycol (molecular weight 2000) into the reactor, vacuum, and pass N 2 The reaction temperature is 150°C and the reaction time is 10 hours to obtain a low molecular weight polylactic acid polycarbonate copolymer. The product has a weight average molecular weight of M w 2×10 3 ~5×10 4 .

[0025] (3) The low molecular weight polylactic acid polycarbonate copolym...

Embodiment 2

[0027] (1) Dehydrate 800g of L-lactic acid in a reactor at 110°C, then add 40g of succinic acid, vacuum, and perform polycondensation under the action of 1g of stannous octoate as a catalyst. The pressure in the reactor is 1500Pa. The temperature was 100°C and reacted for 2 hours, then the pressure in the reactor was reduced to below 100Pa, the reaction temperature was increased to 160°C, and the reaction was continued for 10 hours to obtain M w = 8×10 2 ~3.0×10 4 The carboxyl-terminated lactic acid prepolymer;

[0028] (2) Add the carboxyl-terminated lactic acid prepolymer obtained in step (1) and 300 g of polycarbonate 1,6-hexanediol ester diol (molecular weight 3000) into the reactor, vacuum, and pass N 2 The reaction temperature is 170°C, and the reaction time is 10 hours to obtain a low molecular weight polylactic acid polycarbonate copolymer. The product has a weight average molecular weight of M w 2×10 3 ~5×10 4 .

[0029](3) The low molecular weight polylactic acid polycar...

Embodiment 3

[0031] (1) Dehydrate 600g of L-lactic acid in a reactor at 120°C, then add 40g of succinic acid, vacuum, and perform polycondensation reaction under the action of 1g of stannous octoate as a catalyst. The pressure in the reactor is 1800Pa. The temperature is 120°C, react for 3 hours, then the pressure in the reactor is reduced to below 100Pa, the reaction temperature is increased to 170°C, and the reaction is continued for 6 hours to obtain M w = 8×10 2 ~3.0×10 4 The carboxyl-terminated lactic acid prepolymer;

[0032] (2) Add the carboxyl-terminated lactic acid prepolymer obtained in step (1) and 400g of polycarbonate 1,5-pentanediol-1,6-hexanediol ester (molecular weight 4000) into the reactor, and vacuumize , Pass N 2 The reaction temperature is 180℃, and the reaction time is 8 hours to obtain low molecular weight polylactic acid polycarbonate copolymer. The product has a weight average molecular weight of M w 2×10 3 ~5×10 4 .

[0033] (3) Extrude the low molecular weight polyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com