Arc-shaped bridge membrane laminating as-cast finish template and production process thereof

A technology of clear water formwork and production process, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to meet curved bridges, inability to achieve radian bending, poor overall bridge effect, etc., to achieve stable and lightweight shape and shorten construction period. , the effect of quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above-mentioned technical content and structural features of the present invention more easily understood by those skilled in the art, the present application will be further described below in conjunction with the accompanying drawings and technical points.

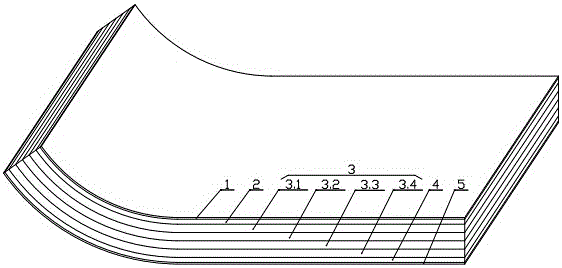

[0032] The arc-shaped bridge film-coated clear water formwork of the present invention is mainly composed of melamine-impregnated paper, poplar veneer and core curtain. Board 2, core curtain 3, lower poplar veneer 4, lower melamine impregnated paper 5. The embryonic order of the core curtain from top to bottom is long curtain 3.1, long curtain 3.2, short curtain 3.3, and long curtain 3.4, that is, the core curtain 3 has four layers in total. The size of the long curtain is 2500×1400×1.8mm, and the size of the short curtain is 1300×2500×2.2mm. The core curtain 3 will be dried to a moisture content below 8%, and then dried in the air after dipping for later use. The upper poplar veneer 2 is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com