A permanently modified phosphogypsum composite thermal insulation formwork and its manufacturing method

A technology of composite thermal insulation and phosphogypsum, applied in chemical instruments and methods, climate sustainability, synthetic resin layered products, etc., can solve the problem of consuming large molds, sites, labor, increasing costs and investment costs, and affecting the ecological environment, etc. problems, to achieve the effect of good tensile and folding resistance, good thermal insulation performance, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Case 1

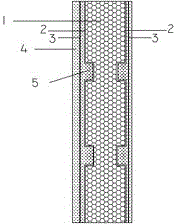

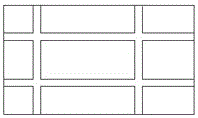

[0022] Such as figure 1 As shown, a permanent modified phosphogypsum composite insulation formwork will be as figure 2 The extruded board with horizontal and vertical grooves shown is placed horizontally, and a layer of interface agent is evenly applied on the outside, with a thickness of about 1mm. The modified phosphogypsum powder is prepared according to the following ratio:

[0023] Calcined phosphogypsum: 56%, cement: 15.1%, fly ash: 20%, quicklime: 4.66%, slag micropowder: 1.6%, vitrified microbeads: 1.1%, latex powder: 0.8%, superplasticizer: 0.22%, waterproofing agent: 0.23%, polypropylene fiber: 0.14%, retarder: 0.15%; the cement mentioned in the above ratio is 42.5R ordinary portland cement sold in the market.

[0024] The latex powder described in the above proportioning is VINNAPAS 5044N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com