A catalyst for catalytic combustion of chlorine-containing volatile organic compounds and its preparation method and application

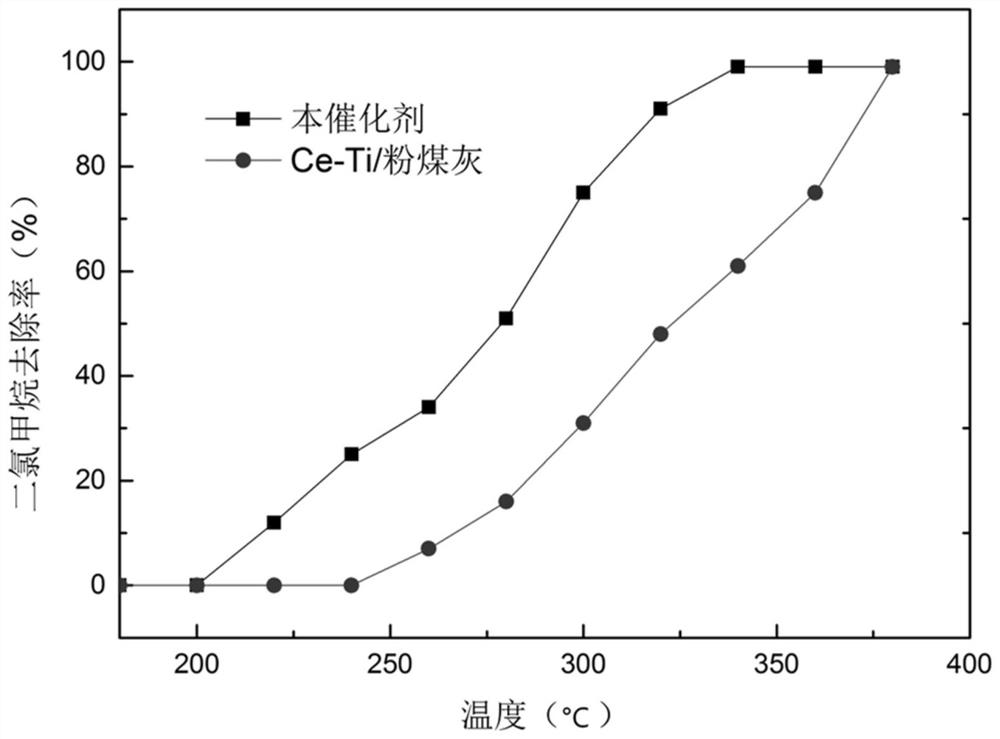

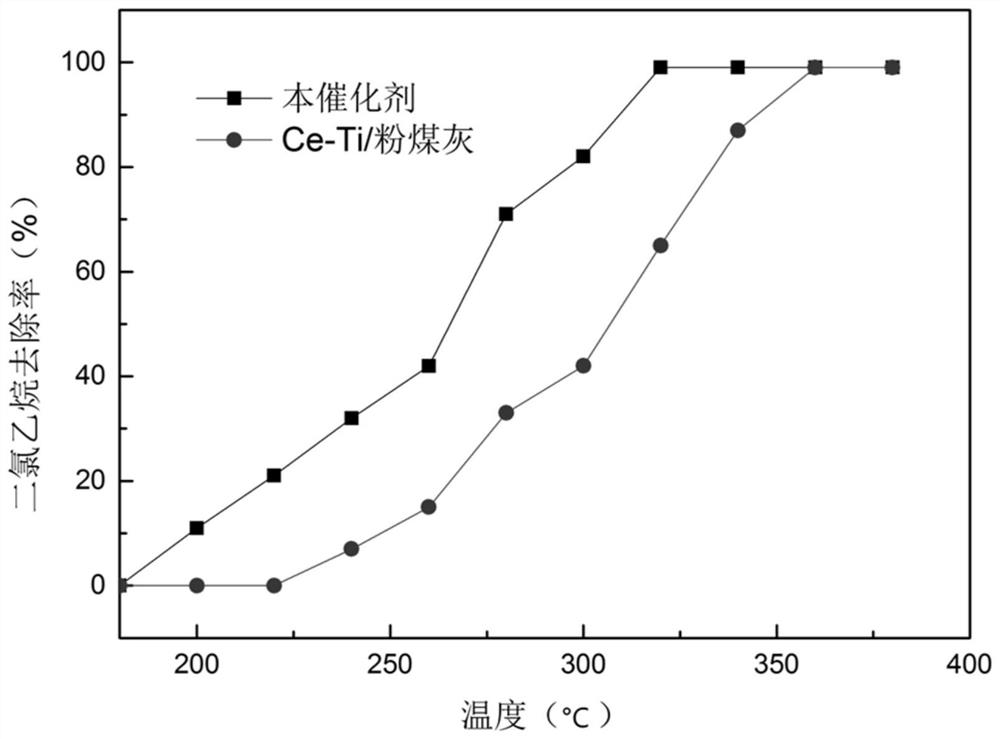

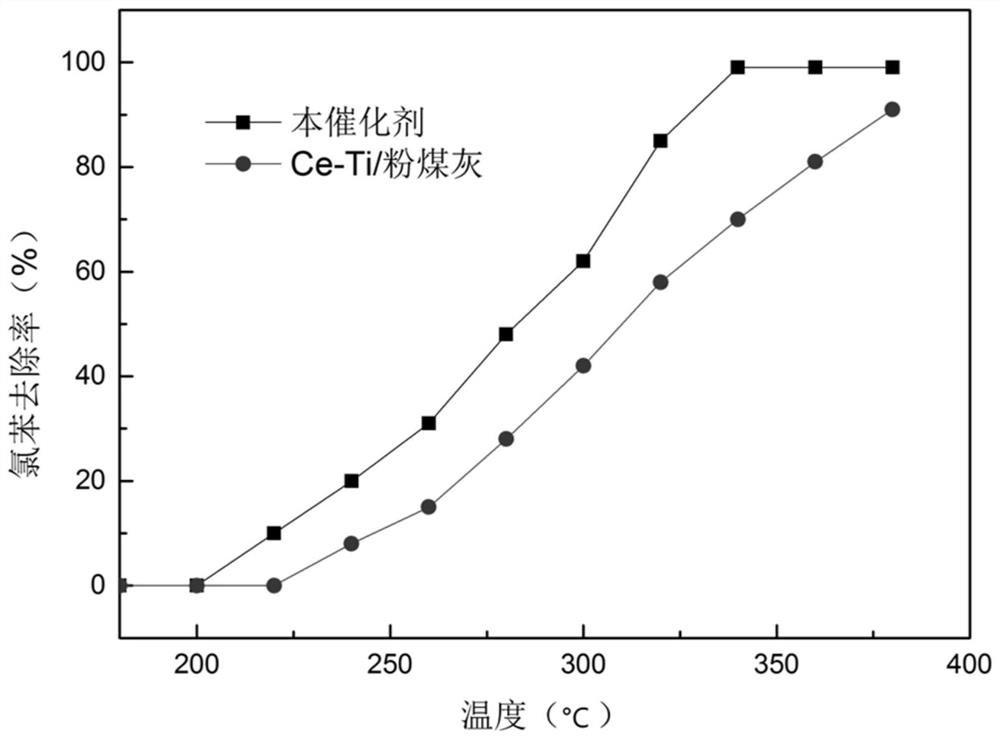

A volatile organic compound, catalytic combustion technology, used in physical/chemical process catalysts, combustion methods, molecular sieve catalysts, etc., can solve the problem of catalysts prone to chlorine poisoning, and achieve the effects of low cost, high adsorption activity, and good catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention relates to a catalyst for catalytic combustion of chlorine containing volatile organic compounds and a preparation method thereof. The raw materials include fly ash, strong oxidizing acid, sodium hydroxide, disodium ethylenediamine tetraacetate, titanium dioxide and cerium nitrate. The mass ratio of fly ash, titanium dioxide, disodium EDTA, deionized water and cerium nitrate is 30:5:2:10:3.

[0033] The specific steps are as follows:

[0034] (1) Pretreatment of fly ash and titanium dioxide: weigh 30 g of fly ash, grind it to 200 mesh, dry it in an oven at 80 ℃ for 3 hours, cool it to room temperature, mix the dried fly ash with 10% hydrochloric acid solution at a material liquid ratio (g / ml) of 5:15, stir it with a magnetic stirrer at 30 ℃ for 2 hours to obtain the mixture liquid, wash and filter the mixture liquid with distilled water for 3 times to neutral, and dry it for 10 hours, Obtain the pretreated fly ash; Weigh 10 g of titanium dioxide, grind it to...

Embodiment 2

[0040]The invention relates to a catalyst for catalytic combustion of chlorine containing volatile organic compounds and a preparation method thereof. The raw materials include fly ash, strong oxidizing acid, sodium hydroxide, disodium ethylenediamine tetraacetate, titanium dioxide and cerium nitrate. The mass ratio of fly ash, titanium dioxide, disodium EDTA, deionized water and cerium nitrate is 40:5:5:20:4.

[0041] The specific steps are as follows:

[0042] (1) Pretreatment of fly ash and titanium dioxide: weigh 40 g of fly ash, grind it to 200 mesh, dry it in an oven at 120 ℃ for 5 hours, cool it to room temperature, mix the dried fly ash with 20% sulfuric acid solution at a material liquid ratio (g / ml) of 5:15, stir it with a magnetic stirrer at 30 ℃ for 4 hours to obtain the mixture liquid, wash and filter the mixture liquid with distilled water for 5 times to neutral, and dry it for 12 hours, Obtain the pretreated fly ash; Weigh 5 g of titanium dioxide, grind it to 200 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com