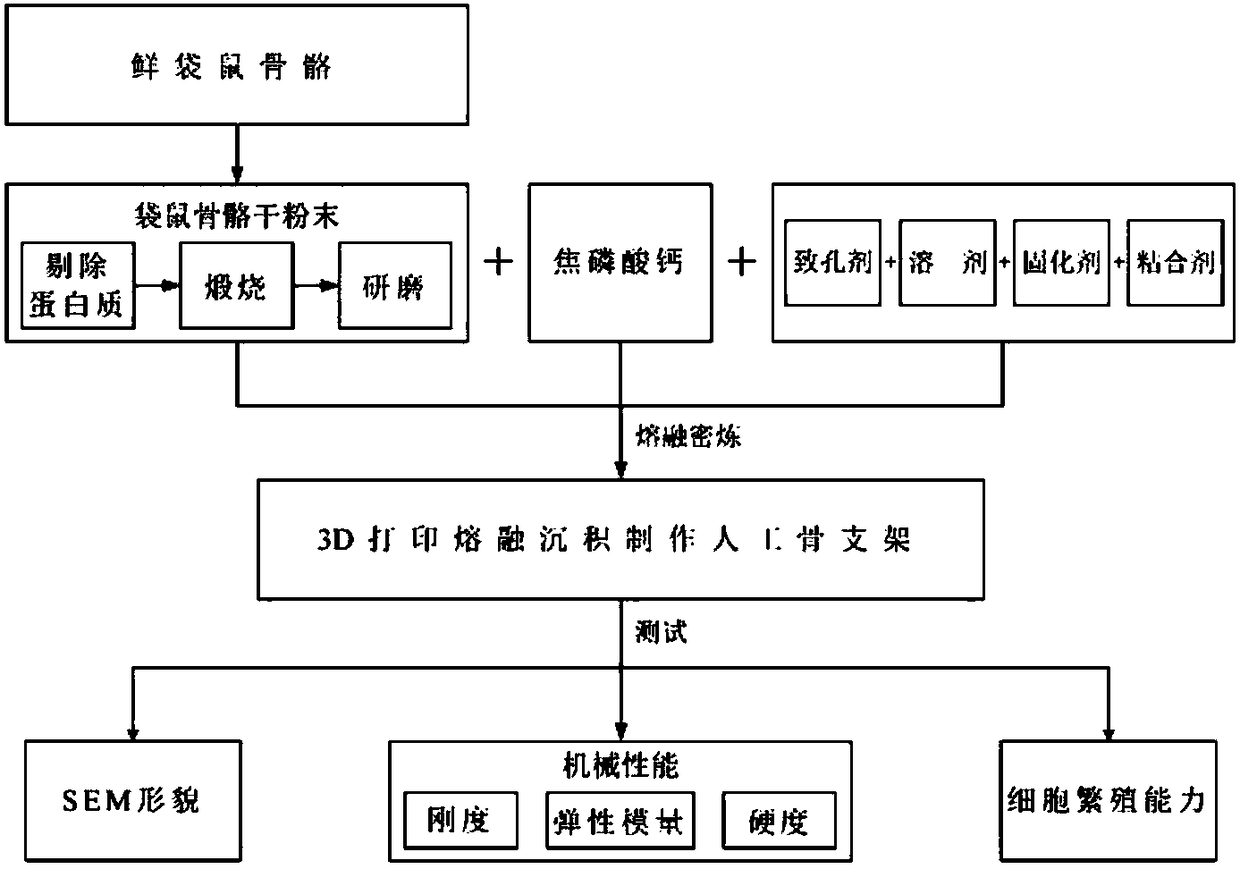

A kind of artificial bone scaffold composite material based on kangaroo bone and its preparation method

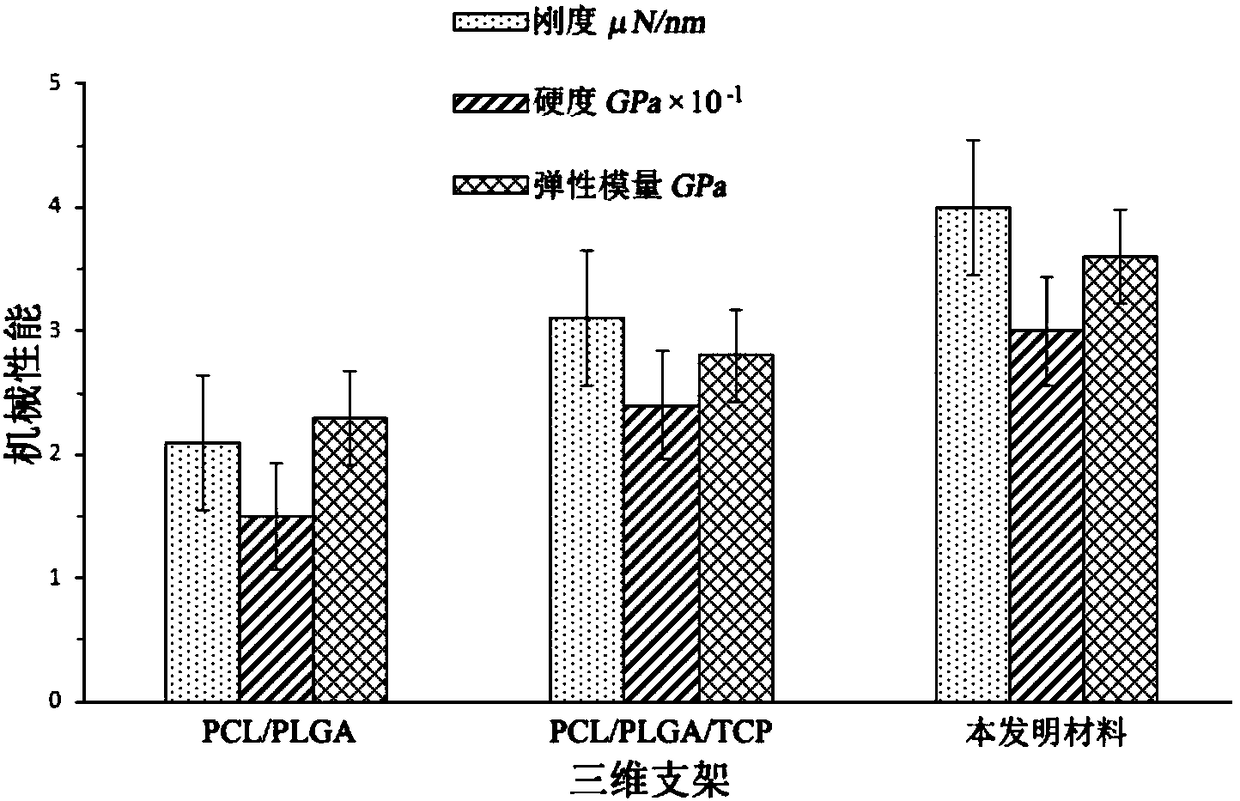

A composite material and artificial bone technology, applied in the field of polymer materials and biomedical materials, can solve the problems of weak compressive strength, secondary injury to the patient's body, insufficient mechanical strength of the stent, etc., to enhance the elastic modulus and avoid stress shielding. , the effect of overcoming mechanical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. The production process of kangaroo bone dry powder

[0054] Step 1: Protein Removal from Kangaroo Femur:

[0055] First, wash the fresh kangaroo femur with clean water, then soak it with 0.8mol / L hydrochloric acid for 1 hour, and then use 4M guanidine hydrochloride solution to dissolve the protein (among them, guanidine hydrochloride is a strong denaturant, which can dissolve the kangaroo femur. of protein). Then cook in boiling water at 100°C for 3 hours. The purpose of boiling is to remove the meat and other substances in the kangaroo bones, then wash the kangaroo femur with distilled water, and put it in a drying oven to keep the temperature at 110°C for about 28 hours, make the kangaroo bones completely dry and then put them into the freezer for 3 hours;

[0056] The second step: calcining it at a temperature of 80°C for 2 hours, increasing the temperature to 20°C / min during the calcination process, and cooling at room temperature for 2 hours;

[0057] Step 3:...

Embodiment 2

[0071] 1. The production process of kangaroo bone dry powder

[0072] Step 1: Protein Removal from Kangaroo Femur:

[0073] First, wash the fresh kangaroo femur with water, then soak it in 0.5mol / L hydrochloric acid for 2 hours, and then dissolve the protein with 6M guanidine hydrochloride solution. Then boil it in boiling water at 100°C for 4 hours, then wash the kangaroo femur with distilled water, put it in a drying box and keep the temperature at 110°C for about 30 hours, make the kangaroo bone completely dry, and then put it in the freezer for 5 hours ;

[0074] The second step: calcining it at a temperature of 65°C for 3 hours, increasing the temperature to 20°C / min during the calcination process, and cooling at room temperature for 2 hours;

[0075] Step 3: Grind into very fine powder particles with a ceramic mortar grinder. The grinder is a TM130 solid particle grinder. Set at 45 minutes. The particle size of kangaroo femur powder is less than 30 μm.

[0076] 2. C...

Embodiment 3

[0081] 1. The production process of kangaroo bone dry powder

[0082] Step 1: Protein Removal from Kangaroo Femur:

[0083] First, wash the fresh kangaroo femur with clean water, then soak it in 1mol / L hydrochloric acid for 1 hour, and then use 5M guanidine hydrochloride solution to dissolve the protein. Then boil it in boiling water at 100°C for 3.5 hours, then wash the kangaroo femur with distilled water, put it in a drying oven and keep the temperature at 110°C for about 29 hours, make the kangaroo bone completely dry, and then put it in the freezer for 4 hours ;

[0084] The second step: calcining it at a temperature of 90°C for 2.5 hours, increasing the temperature to 20°C / min during the calcination process, and cooling at room temperature for 2 hours;

[0085] Step 3: Grind into very fine powder particles with a ceramic mortar grinder. The grinder is a TM130 solid particle grinder. Set at 35 minutes. The particle size of kangaroo femur powder is less than 30 μm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com