A preparation method of burning oxidized carbon fiber reinforced phenolic resin friction composite material

A phenolic resin, fiber reinforced technology is applied in the field of preparation of sintered carbon oxide fiber reinforced phenolic resin friction composite materials, which can solve the problems of human health hazards, cumbersome steps, limitations, etc. The effect of improving tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

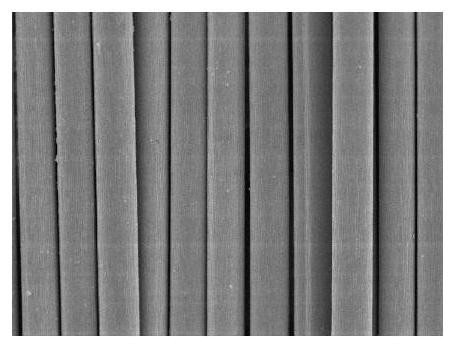

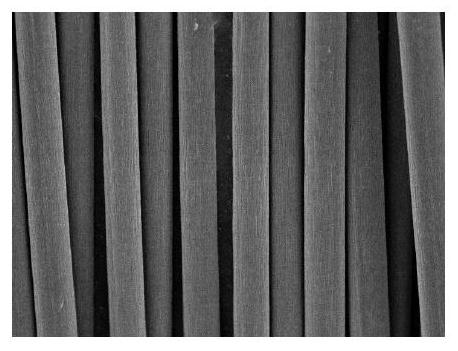

Image

Examples

preparation example Construction

[0025] A method for preparing a burning carbon fiber reinforced phenolic resin friction composite material, comprising the following steps:

[0026] Step 1: Burn the carbon fiber with butane gas for 0-60min, and fix the distance between the muzzle and the carbon fiber at 5-8cm. After the reaction is over, wash the carbon fiber sample with deionized water and dry it at 70°C to obtain the surface Activated carbon fiber.

[0027] Step 2: the modified β-Si 3 N 4 , phenolic resin, and H256 curing agent are mixed in ethanol according to the mass ratio of 1-5:80-90:5-10 to make a mixed phenolic resin ethanol solution.

[0028] Step 3: Immerse the burned carbon fiber in step 1 in the ethanol solution of mixed resin in step 2, wherein the mass ratio of burned carbon fiber to mixed resin is 30-40:60-70, so that it can penetrate evenly In the fired carbon fiber. Take out the impregnated carbon fiber cloth and put it in an oven, remove the ethanol solvent at 70°C to obtain the ignited...

Embodiment 1

[0030] Step 1: Reflux 8g of carbon fibers with acetone to remove surface pollutants and sizing agents, wash them with deionized water and dry them. Then, the carbon fiber was burned with butane gas for 10 minutes, and the distance between the muzzle and the carbon fiber was fixed at 5 cm. After the reaction, the carbon fiber sample was washed with deionized water and dried at 70°C to obtain surface-activated carbon fiber.

[0031] Step 2: Add 0.4g of modified β-Si 3 N 4 , 17.6g phenolic resin, 2g H256 curing agent mixed in 50mL ethanol to make a mixed phenolic resin ethanol solution.

[0032] Step 3: Immerse the burned carbon fiber in step 1 in the mixed resin ethanol solution in step 2, wherein the mass ratio of burned carbon fiber to mixed resin is 40:60, so that it can evenly penetrate into the burned in carbon fiber. Take out the impregnated carbon fiber cloth and put it into an oven, remove the ethanol solvent at 70°C to obtain a carbon fiber reinforced phenolic resin ...

Embodiment 2

[0034] Step 1: Reflux 8g of carbon fibers with acetone to remove surface pollutants and sizing agents, wash them with deionized water and dry them. Then, the carbon fiber was burned with butane gas for 60 minutes, and the distance between the muzzle and the carbon fiber was fixed at 8 cm. After the reaction, the carbon fiber sample was washed with deionized water and dried at 70°C to obtain surface-activated carbon fiber.

[0035] Step 2: Add 0.4g of modified β-Si 3 N 4 , 17.6g phenolic resin, 2g H256 curing agent mixed in 50mL ethanol to make a mixed phenolic resin ethanol solution.

[0036] Step 3: Immerse the burned carbon fiber in step 1 in the mixed resin ethanol solution in step 2, wherein the mass ratio of burned carbon fiber to mixed resin is 40:60, so that it can evenly penetrate into the burned in carbon fiber. Take out the impregnated carbon fiber cloth and put it in an oven at 70°C to remove the ethanol solvent to obtain a carbon fiber reinforced phenolic resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear rate | aaaaa | aaaaa |

| wear rate | aaaaa | aaaaa |

| wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com