Low-cost biology base full degradation thin film and preparation method thereof

A bio-based, fully degradable technology, applied in the field of fully biodegradable materials, can solve the problems of high cost of fully biodegradable films, difficult to popularize and apply, and achieve the effect of promoting promotion and application, low cost, and solving the problem of "white pollution".

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

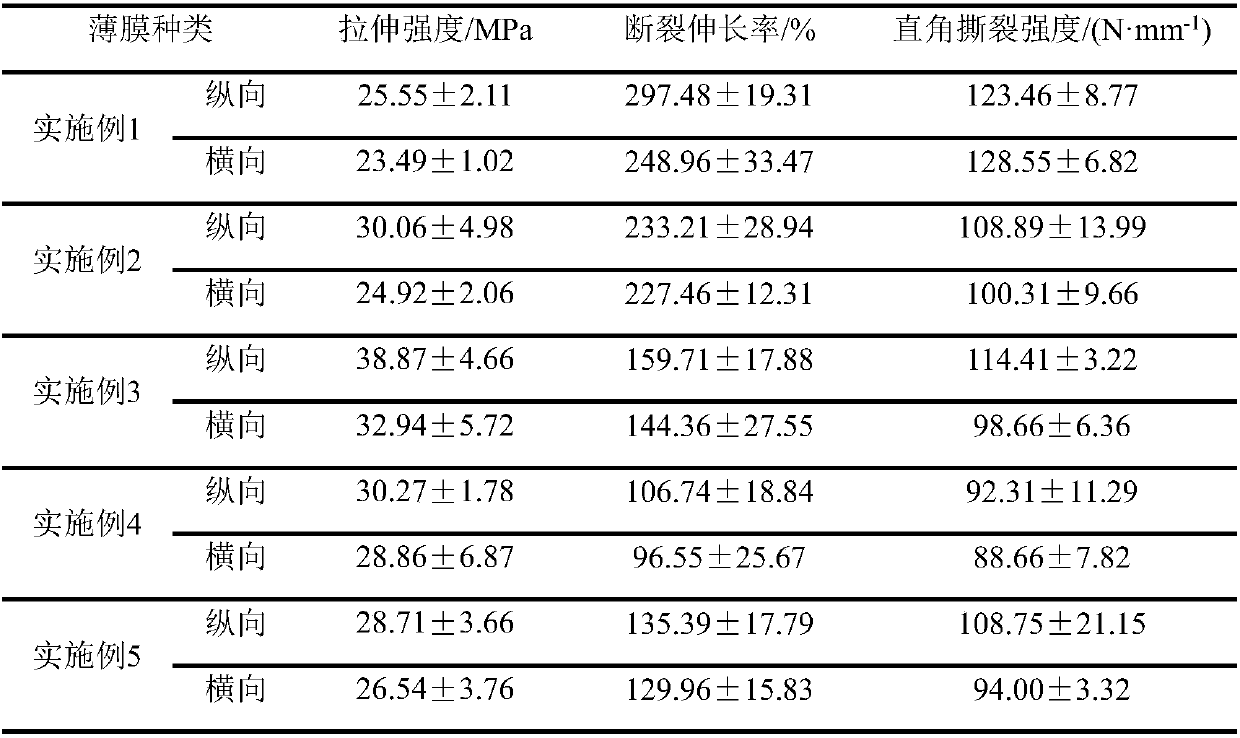

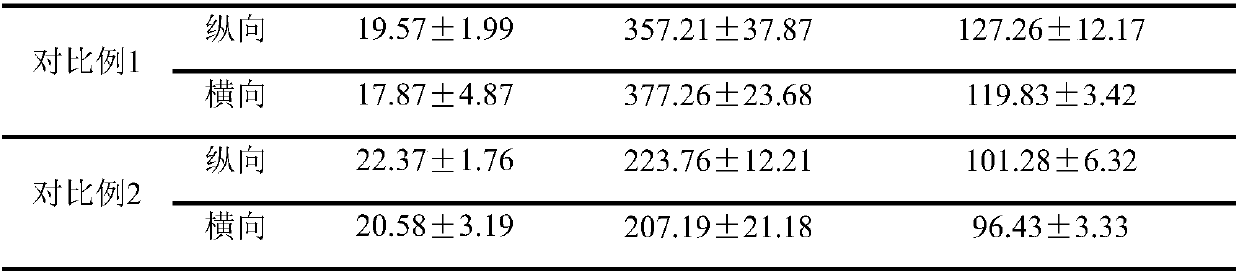

Examples

Embodiment 1

[0027] The low-cost bio-based fully degradable film material consists of the following raw materials in parts by mass: 15 parts of polyglycolide, 25 parts of corn starch, 55 parts of polybutylene adipate / terephthalate, 1.25 parts of glycerol, 2.5 parts of ethylene glycol, 5 parts of ethylene butyl acrylate grafted glycidyl methacrylate, 0.5 parts of citric acid, 0.75 parts of acetyl tributyl citrate, 0.3 parts of maleic anhydride, 0.2 parts of antioxidant 164, 2- 0.2 parts of (2'-hydroxy-5'-methylphenyl)benzotriazole.

[0028] Preparation of low-cost bio-based fully degradable films:

[0029] First, mix polyglycolide, maleic anhydride and acetyl tributyl citrate evenly, then add them to a parallel co-rotating twin-screw extruder for blending and extrusion, and set the temperature in the 1-7 zone of the extruder to 160°C in sequence. 180°C, 230°C, 230°C, 230°C, 230°C, 230°C, head temperature is 220°C, to prepare plasticized and capped PGA modified material;

[0030] Then corn...

Embodiment 2

[0036] The low-cost bio-based fully degradable film material is composed of the following raw materials in parts by mass: 20 parts of polyglycolide, 30 parts of corn starch, 45 parts of polyadipate / butylene terephthalate, 4 parts of formamide, urea 2 parts, 5 parts of ethylene butyl acrylate grafted glycidyl methacrylate, 0.6 parts of citric acid, 1 part of acetyl tributyl citrate, 0.4 parts of maleic anhydride, 1640.2 parts of antioxidant, 2-(2'- 0.2 parts of hydroxy-5'-methylphenyl)benzotriazole.

[0037] Preparation of low-cost bio-based fully degradable films:

[0038] First, mix polyglycolide, maleic anhydride and acetyl tributyl citrate evenly, then add them to a parallel co-rotating twin-screw extruder for blending and extrusion, and set the temperature in the 1-7 zone of the extruder to 160°C in sequence. 180°C, 230°C, 230°C, 230°C, 230°C, 230°C, head temperature is 220°C, to prepare plasticized and capped PGA modified material;

[0039] Then add cornstarch, formamid...

Embodiment 3

[0045] The low-cost bio-based fully degradable film material is composed of the following raw materials in parts by mass: 25 parts of polyglycolide, 35 parts of corn starch, 35 parts of polybutylene adipate / terephthalate, and ethylene diformamide 12.25 parts, 5 parts of ethylene butyl acrylate grafted glycidyl methacrylate, 0.7 parts of citric acid, 1.25 parts of acetyl tributyl citrate, 0.5 parts of maleic anhydride, 0.2 parts of antioxidant 164, 2-(2' 0.2 parts of -hydroxy-5'-methylphenyl)benzotriazole.

[0046] Preparation of low-cost bio-based fully degradable films:

[0047] First, mix polyglycolide, maleic anhydride and acetyl tributyl citrate evenly, then add them to a parallel co-rotating twin-screw extruder for blending and extrusion, and set the temperature in the 1-7 zone of the extruder to 160°C in sequence. 180°C, 230°C, 230°C, 230°C, 230°C, 230°C, head temperature is 220°C, to prepare plasticized and capped PGA modified material;

[0048] Then cornstarch and et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com